Thermal insulation structure with adjustable cold core for growth of sapphire single crystals by virtue of kyropoulos method

A technology of bubble growth and sapphire, which is applied in the field of high temperature thermal insulation structure for growing sapphire (α-Al2O3 single crystal) by bubble growth, to achieve the effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

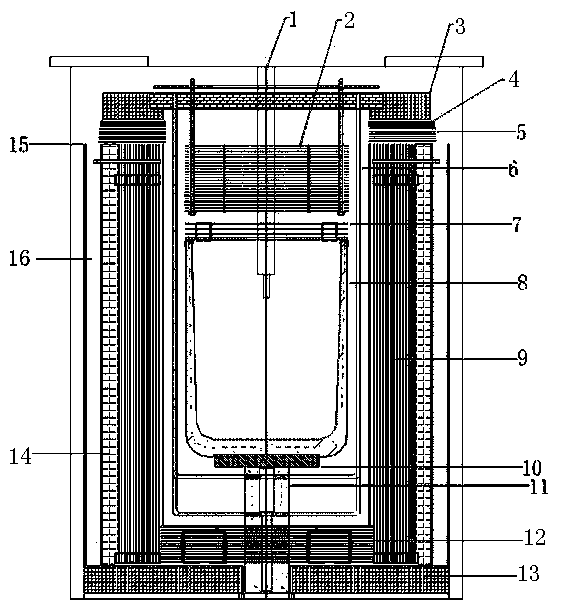

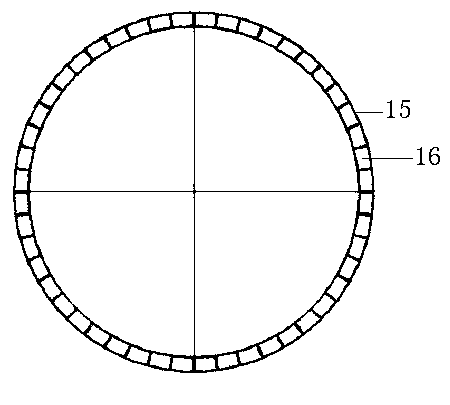

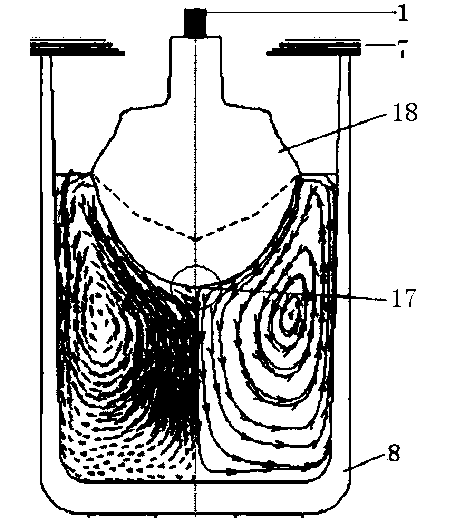

[0034] Such as figure 1 As shown, the thermal insulation structure applied to the Kyropoulos sapphire single crystal growth of the present invention is arranged on the heat shield in the stainless steel barrel 15, and the heat shield is mainly made of two materials of tungsten and molybdenum, including horizontal heat shields 2, 5, 7, 12, vertical heat shield 9.

[0035] Among them, the horizontal heat shield 2 is a circular ring with a central opening, and the central opening is a seed crystal lifting rod 1 that penetrates through it. During the crystal growth process, it plays a role in lifting and rotating the crystal. The grown sapphire Crystals are housed in crucible 8 . The horizontal heat shield 5 is arranged above the vertical heat shield 9 and is a larger circular ring with a central opening, which can accommodate the horizontal heat shie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com