Downhole booster

A technology of supercharger and supercharger unit, which is applied in the direction of drilling with liquid/gas jets, etc., can solve the problems of poor manufacturability, poor sealing of the reversing valve of the downhole supercharger, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

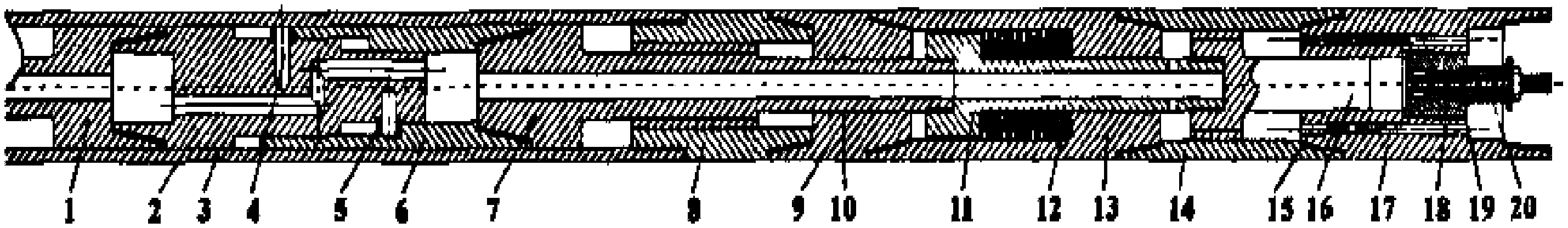

[0007] During the drilling process, the drilling fluid relies on hydraulic action to drive the downhole screw motor to rotate. The power shaft 2 and the power conversion body 6 convert the rotary motion of the screw motor into the reciprocating motion of the plunger 16, and drive the spline shaft 7, butterfly The reed shaft 11 and plunger 16 move downward, and the valve closes to pressurize the drilling fluid in the cylinder; driven by the butterfly spring 12, the spline shaft 7, butterfly spring shaft 11, and plunger 16 move upward, and the valve opens to suck Drilling fluid, such that one reciprocating movement completes one pressurization process of the supercharger.

[0008] During the entire pressurization process, the entry and exit of high-pressure drilling fluid are completed by a valve body. Drilling fluid flows out from the transmission shaft 1 of the screw pump, enters the inner flow channel of the butterfly spring shaft 11 through the inner flow channel of the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com