Vertical shaft shield tunneling machine

A shield machine and shaft technology, which is applied in shaft equipment, sinking, mining equipment, etc., can solve the problems of low shaft construction efficiency and achieve the effects of improving support efficiency, high excavation efficiency, and fast excavation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

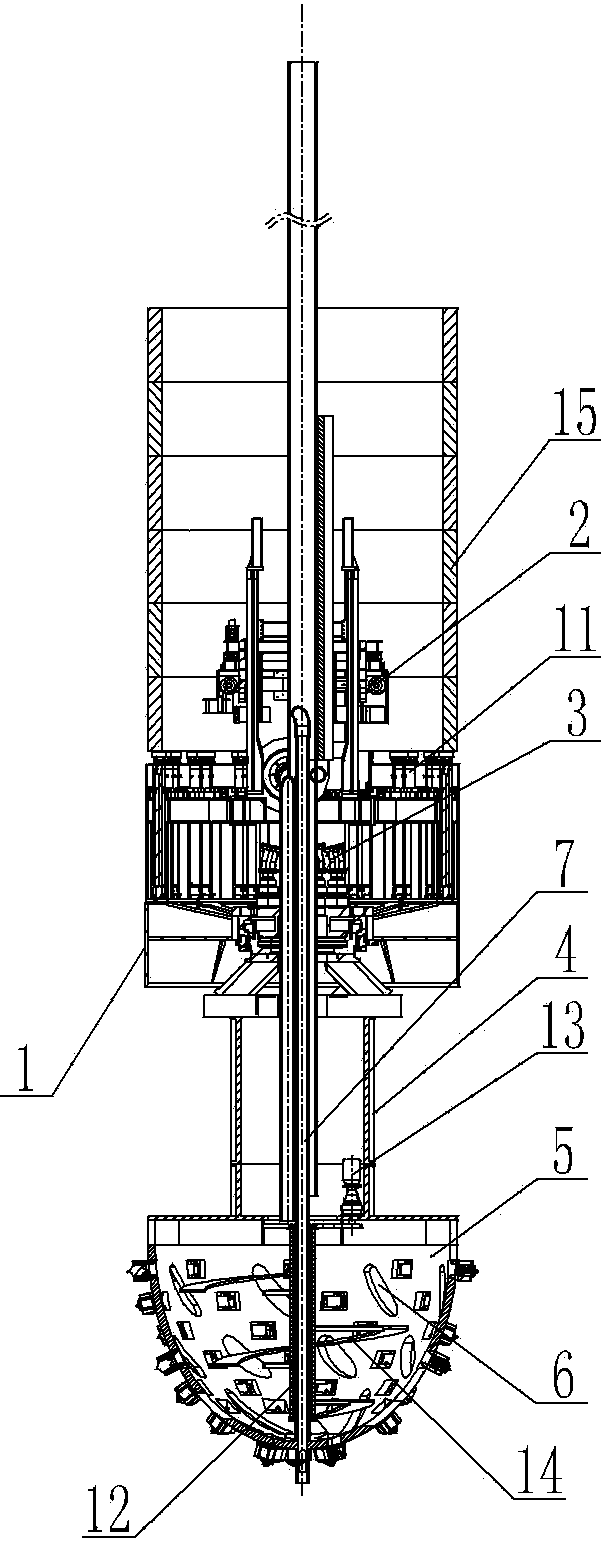

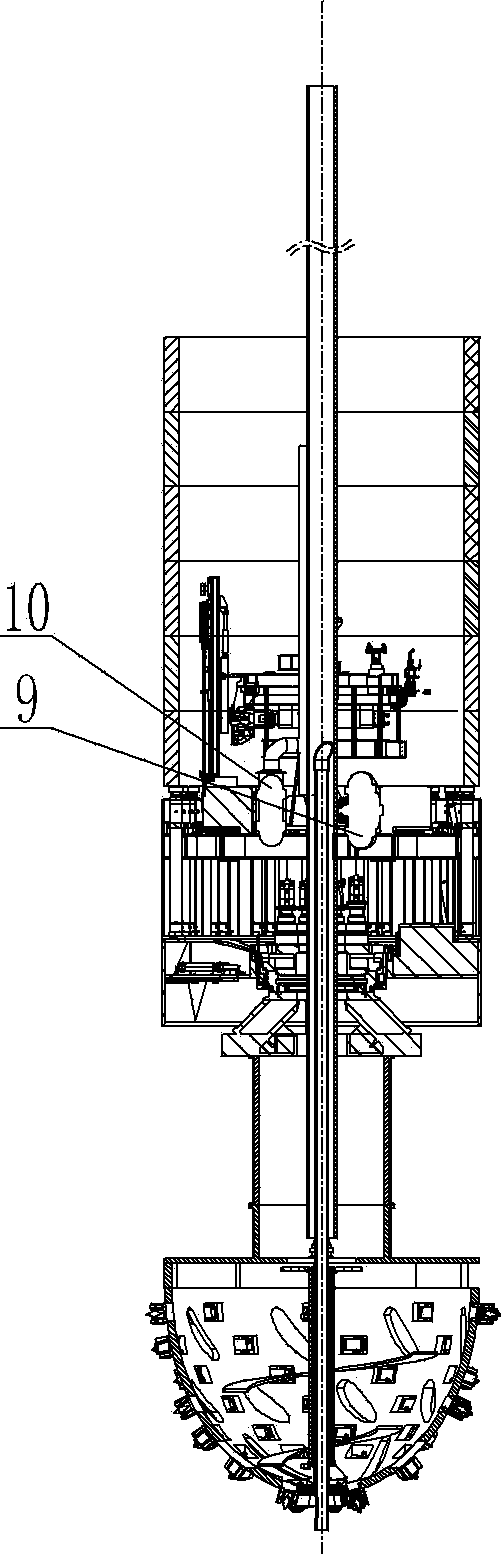

[0016] An embodiment of a shaft shield machine, in figure 1 and figure 2 Among them, the shield body 1 is a cylindrical shield body, and a segment assembly machine 2 is arranged at the rear of the shield body 1. The segment assembly machine 2 here is a segment assembly machine in the prior art, and its structure is similar to that of The working mode is the same as the segment assembly machine of the subway tunnel shield machine in the prior art, and will not be described in detail here. A cutter head drive system 3 is provided inside the shield body 1. The cutter head drive system 3 here is a gear drive system, which has a drive gear driven by a hydraulic motor. The hydraulic motor is fixed on the shield body 1, and the drive gear and the ring gear Engaging transmission, the ring gear is fixed together with the rear portion of the connecting cylinder 4. The connecting cylinder 4 is arranged on the shield body 1 through the slewing support of the main bearing, so that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com