a wind turbine

A technology for wind power generators and generators, which is applied in the direction of wind motor combinations, wind engines, wind power generation, etc. It can solve the problems of easy vibration and noise of the unit, lengthening of the axial dimension of the unit, and increase of the width of the nacelle, so as to reduce assembly and Debugging time, reduced maintenance requirements, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

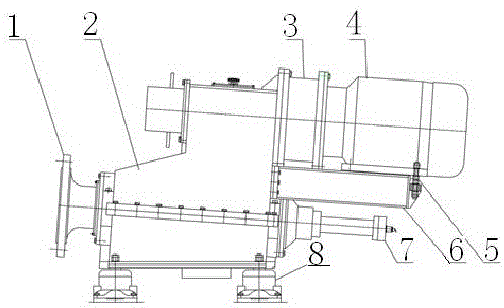

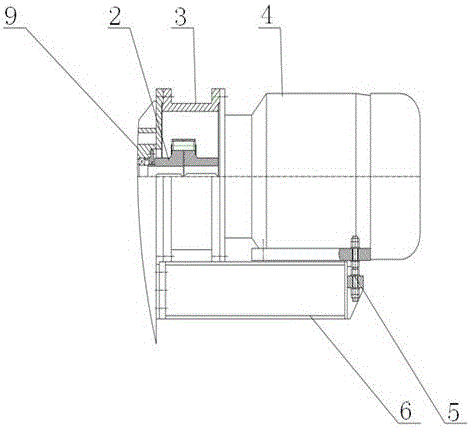

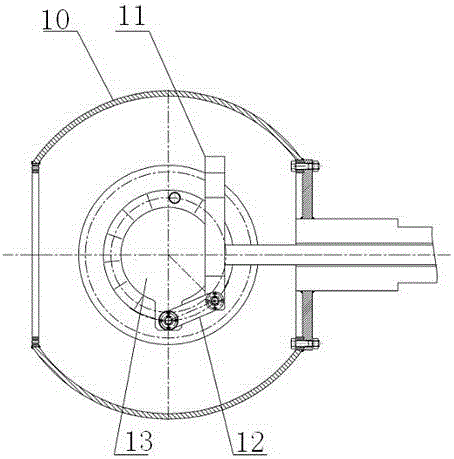

[0029] A wind turbine, such as figure 1 As shown, the wind power generating set is mainly composed of a gear box, a generator, a wind wheel and a nacelle chassis, and the gear box 2 is used as a body; It is connected with the variable pitch oil cylinder 7 through a flange, and the transmission shaft is arranged in a rotary manner (such as Figure 7 , 8 shown); the support frame 6 is fixed on the gear box 2, and the contact surface of the generator and the gear box is regulated by the adjustable jackscrew 5 on the support frame 6 (as figure 2 shown);

[0030] The low-speed shaft of the gearbox 2 is connected to the wheel hub 10 as the main shaft, the front and rear bearings of the low-speed shaft of the gearbox are used as the main shaft bearings, and the high-speed shaft of the gearbox is connected to the generator 4 flange through the connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com