Hydraulic synchronous control mechanism with compensating function

A control mechanism and hydraulic synchronization technology, applied in mechanical equipment, fluid pressure actuating devices, servo motors, etc., can solve the problems of complex hydraulic and electrical control methods, high maintenance costs, and high system oil cleanliness, and achieve electrical control. Simple method, high reliability and high synchronization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention relates to a novel hydraulic synchronous control mechanism with compensation in the field of hydraulic technology, in particular to a novel hydraulic synchronous control mechanism for synchronizing multiple hydraulic cylinders.

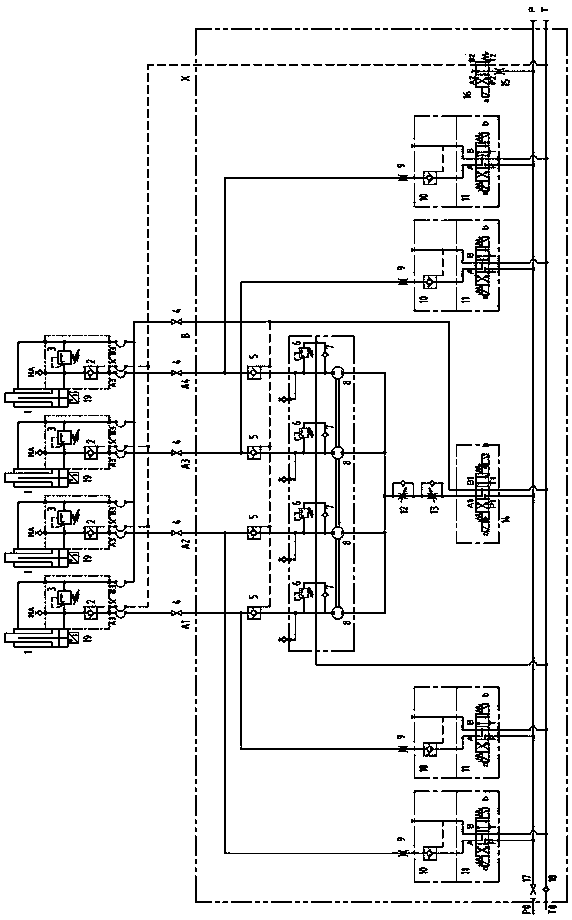

[0023] see figure 1 , the specific structure of a hydraulic synchronous control mechanism with compensation involved in the present invention is:

[0024] Including the main working circuit and compensation circuit; among them,

[0025] The main working circuit includes an oil cylinder 1 provided with a first hydraulic control check valve 2, a first relief valve 3 and a displacement sensor 19, and the oil inlet A3 of the first hydraulic control check valve 2 passes through the first ball valve 4 in sequence , the control of the second hydraulic control check valve 5, the second relief valve 6, the first check valve 7, the synchronous motor 8, the second throttle valve 12, the third throttle valve 13 and the electro-hydraulic reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com