Test device for flow performance characteristics of three-way intake and exhaust pipes of internal combustion engines

A technology of flow performance and test device, applied in the direction of internal combustion engine testing, etc., can solve the problems of complicated piping system, huge system, inability to measure the flow characteristics of three-way pipes, etc., and achieve the effects of flexible operation, high versatility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

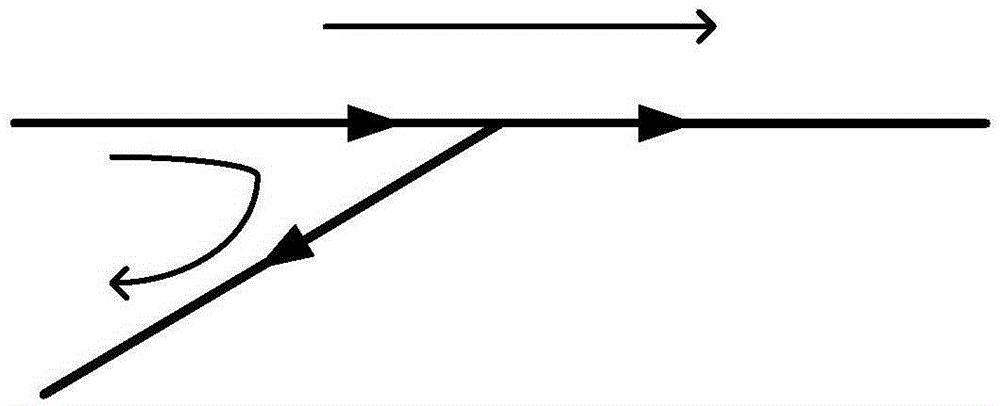

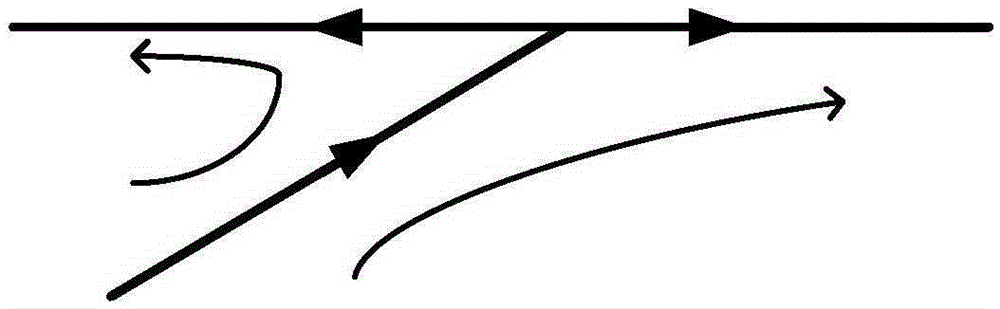

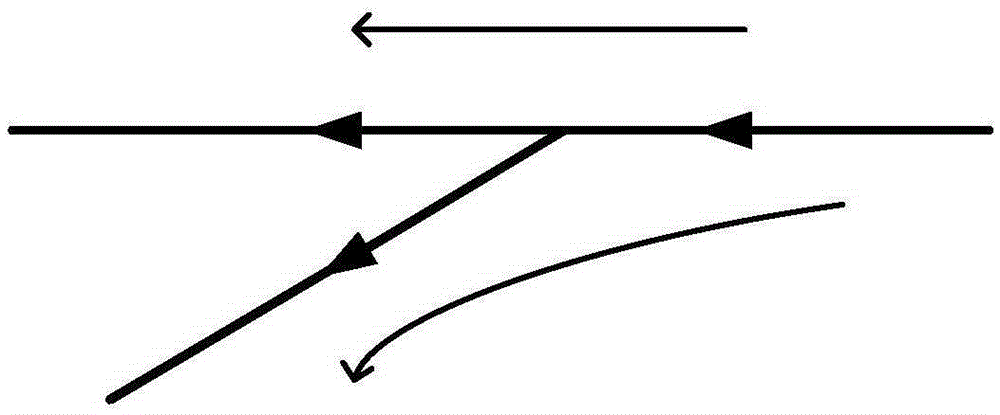

[0034] Such as Figure 7 As shown, a flow performance characteristic test device of a three-way intake and exhaust pipe of an internal combustion engine in a preferred embodiment of the present invention includes a test piece 701, a blower fan 702, a motor 703, a flow piping system, a regulating valve, and a steady flow rate gauges, sensors, surge tanks, transition pipes and flexible pipes. Among them, the test piece 701 is a three-way pipe with three ports, namely the first port 704, the second port 705 and the third port 706; the flow piping system includes three pipelines, respectively the first pipeline 707, the second The pipeline 714 and the third pipeline 721 , these three pipelines are matched with the three ports of the test piece 701 respectively.

[0035] Specifically, the first port 704 of the test piece 701 is connected to one end of the first pipeline 707. The first pipeline 707 is composed of a common pipeline and a branch pipeline, and the first steady flow fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com