Anti-condensation protection system and anti-condensation protection method of laser output port

A technology for protection system and output port, applied in the direction of control/regulation system, instrument, non-electric variable control, etc., can solve the problems of low precision, burnout of optical fiber, low degree of automation, etc., and achieve strong real-time performance, strong adaptability, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

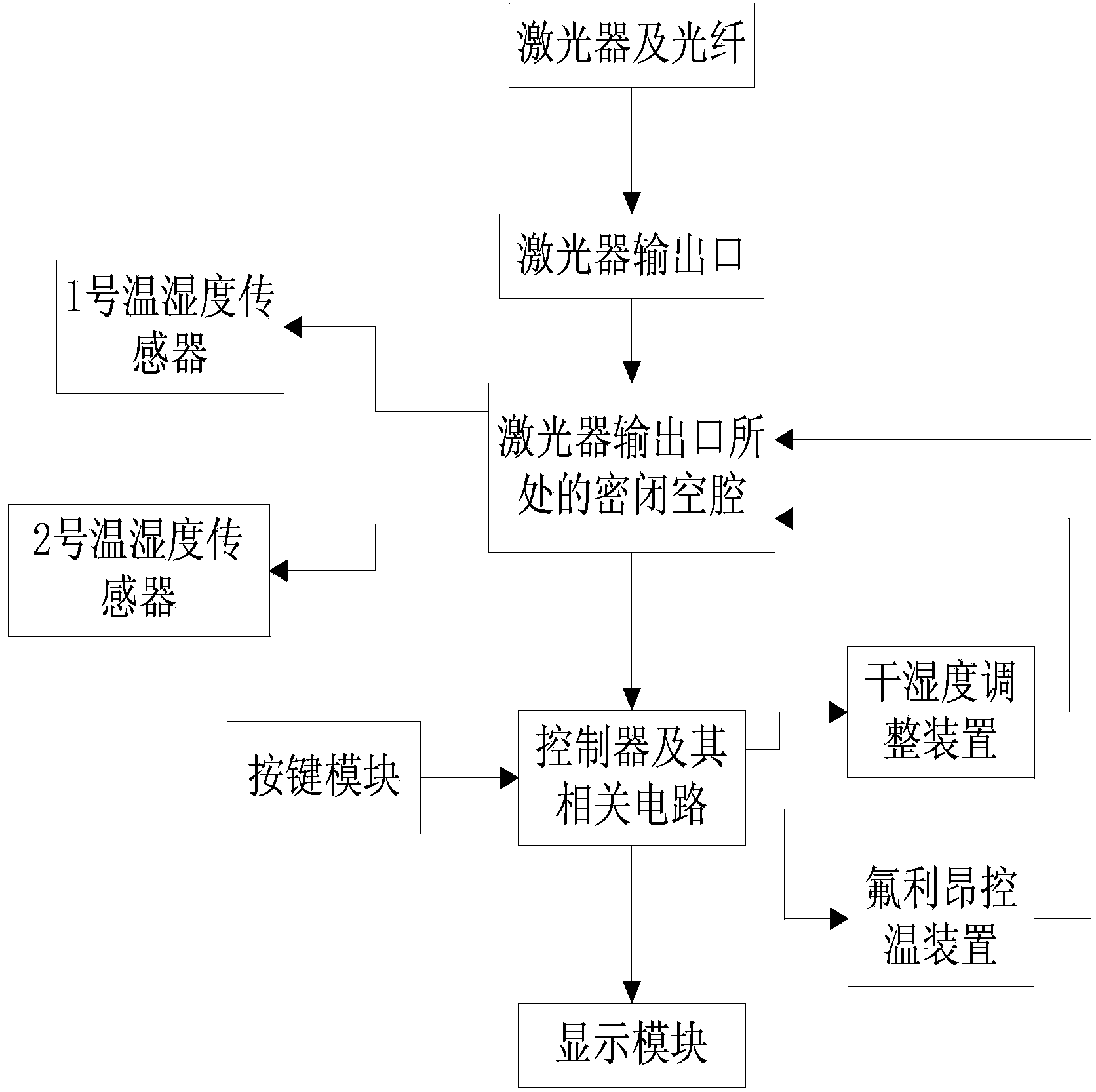

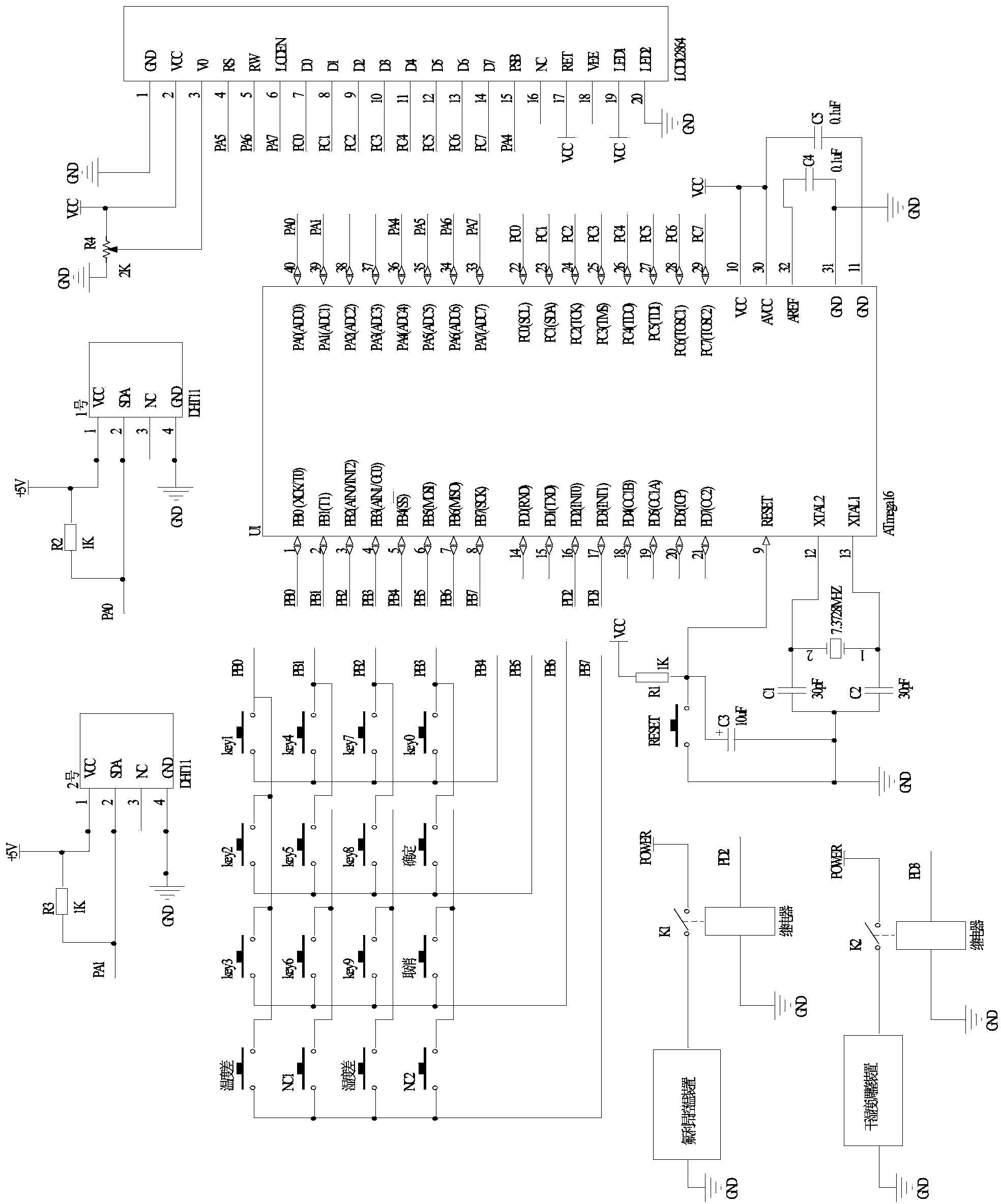

[0023] like figure 1 As shown, an anti-condensation protection system at the laser output port is composed of seven parts: No. 1 temperature and humidity sensor: used to measure the temperature and humidity inside the airtight cavity where the laser output port is located; No. 2 temperature and humidity sensor: used for Measure the temperature and humidity of the external environment where the airtight cavity where the laser output port is located; display module: used to display relevant information; controller and related circuits: used for data processing and control; key module: used for function setting of the system and parameter input; Freon temperature control device: used to control the temperature in the airtight cavity where the laser output port is located is consistent with the external ambient temperature; dry humidity adjustment device: used to control the temperature in the airtight cavity where the laser output port is located The humidity is consistent with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com