Packaging-after etching three-dimensional system-on-chip upright stacking packaging structure and technology method

A system-level chip, etch first and then seal technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problem of difficult to control the quality of interconnecting solder balls between packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

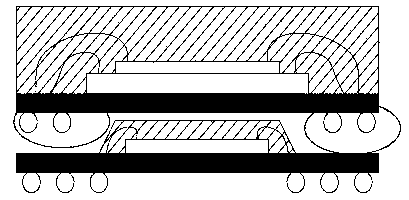

[0201] Embodiment 1. Single-layer circuit single-chip formal mounting single-turn pins

[0202] See Figure 27 , Is a schematic structural view of Embodiment 1 of the three-dimensional system-on-chip front-mount stack package structure of the present invention, which is etched and then sealed. It includes a base island 1 and a pin 2. The front surface of the base island 1 is provided with a conductive or non-conductive adhesive material 3 There is a chip 4, the front surface of the chip 4 and the front surface of the pin 2 are connected by a metal wire 5, and a conductive pillar 6 is provided on the front surface of the pin 2. The peripheral area of the base island 1 and the base island 1 The area between pin 2 and pin 2, the area between pin 2 and pin 2, the area above base island 1 and pin 2, the area below base island 1 and pin 2, and the chip 4, metal line 5 and The conductive pillars 6 are all encapsulated with a plastic molding compound 7. The plastic molding compound 7 i...

Embodiment 2

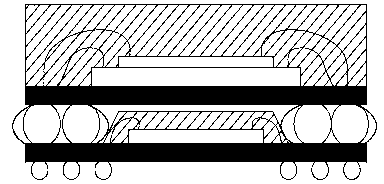

[0256] Embodiment 2. Stacked J-shaped foot package

[0257] See Figure 28 , Is a schematic structural diagram of Embodiment 2 of the three-dimensional system-on-chip front-mount stacked package structure of the present invention, which is etched and then sealed. The difference between Embodiment 2 and Embodiment 1 is that the outer corner of the package body 9 is a J-shaped foot.

Embodiment 3

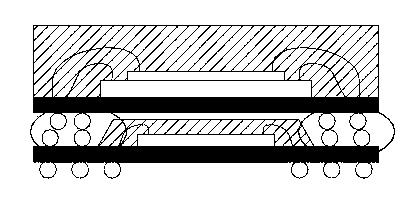

[0258] Embodiment 3. Stacked L-shaped foot package

[0259] See Figure 29 , Is a schematic structural diagram of Embodiment 3 of the three-dimensional system-on-chip front-mount stack package structure of the present invention, which is etched and then sealed. The difference between Embodiment 3 and Embodiment 1 is that the outer corner of the package body 9 is an L-shaped foot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com