Sliding bearing plate sintering method and supporting frame used in method

A technology for sliding bearings and plates, which is applied in the sintering method of sliding bearing plates and the support used in the method, which can solve the problems of inability to ensure the heat distribution between layers and the uniformity of sintering atmosphere, reduce the performance of sintered products, and unstable sintering quality, etc. problems, to achieve the effect of increasing production quantity, improving efficiency, and reasonable structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

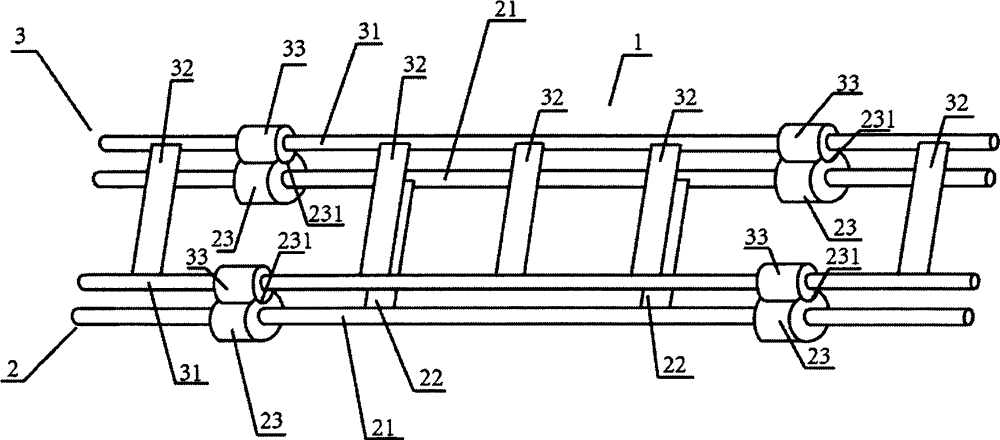

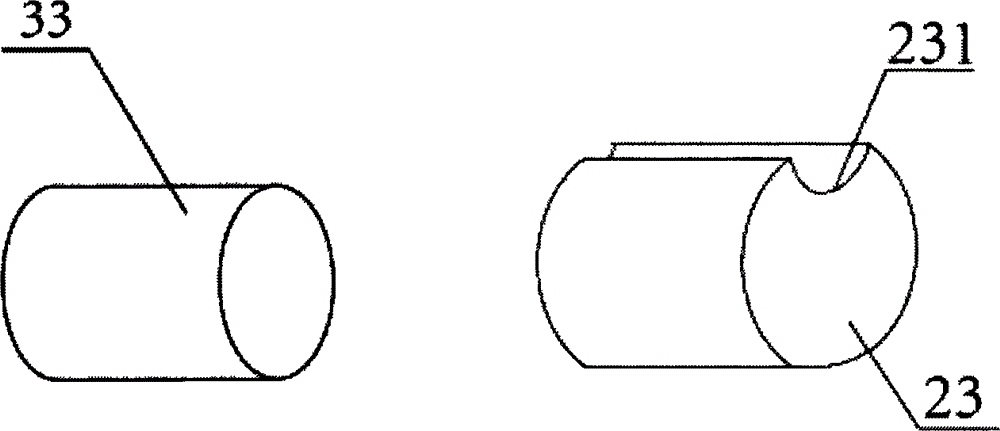

[0050] See attached Figure 1-2 , a support 1 for sliding bearing plate sintering, including an A discharge layer 2 and a B discharge layer 3; the A discharge layer 2 includes two support rods 21 and two connecting rods 22; the two support rods Both ends are covered with fixing pieces 23; all fixing pieces are in the shape of a cylinder, and the surface is provided with a concave surface 231 with an opening upward; the B discharging layer 3 includes two support rods 31 and five connecting rods 32; all Both ends of the support rod are covered with fixing parts 33; all the fixing parts are in the shape of a cylinder; all the fixing parts can be correspondingly snapped into the concave surface 231; among the five connecting rods, three connecting rods are located at the fixing parts at both ends of the supporting rod Between, there is a connecting rod between one fixing part and the end point of the support rod close to the fixing part, and there is a connecting rod between the o...

Embodiment 2

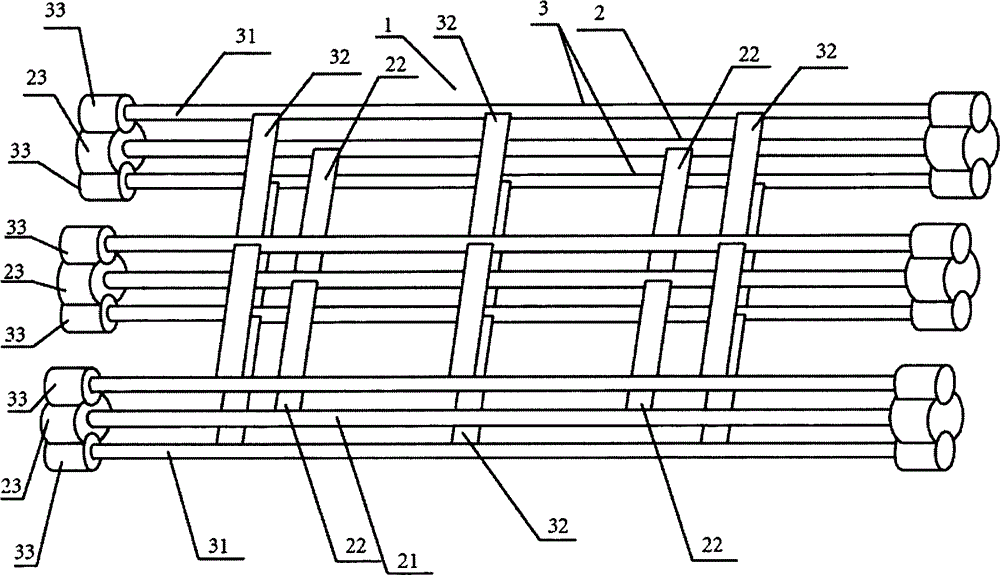

[0053] See attached Figure 3-4 , a support 1 for sliding bearing plate sintering, including an A discharge layer 2 and a B discharge layer 3; the A discharge layer 2 includes three support rods 21 and four connecting rods 22; both ends of all support rods are Covered with fixing parts 23; all fixing parts are in the shape of a cylinder, and the surface is provided with a concave surface 231 with an opening facing upward and a concave surface 232 with an opening facing downward; the B discharging layer 3 includes three support rods 31 and six connecting rods 32; Both ends of all support rods are covered with fixing parts 33; all fixing parts are in the shape of a cylinder; all fixing parts can be snapped into the corresponding concave surface 231 and concave surface 232;

[0054] The support rod is connected to the connecting rod by welding; the total number of layers of the discharge layer is 3 layers, and the A discharge layer is located between the two B discharge layers; t...

Embodiment 3

[0056] See attached Figure 5-6 , a support 1 for sliding bearing plate sintering, including an A discharge layer 2 and a B discharge layer 3; the A discharge layer 2 includes three connecting rods 22 and two support rods 21; the two support rods 21 Both ends are covered with fixing parts 23; all fixing parts are in the shape of a cylinder, and its surface is provided with a concave surface 232 with an opening facing down; A winding knot 221 and a winding knot 222 are formed on the rod; the winding knot 221 and the winding knot 222 are respectively in contact with the support rods of the B discharge layer; among the three connecting rods, one connecting rod is located between the fixing parts at both ends of the supporting rod, and one The connecting rod is located between one fixing part and the end point of the supporting rod close to the fixing part, and one connecting rod is located between the other fixing part and the end point of the supporting rod close to the fixing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com