Red mud modification method, modified product and its application in adsorption of brilliant blue dye

A technology of modified compounds and blue dyes, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as environment, safety and waste of resources, occupation of land resources, hidden dangers of ecological environment, etc. To achieve the effect of convenient material acquisition, large specific surface area and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The red mud is washed to neutral, dried, ball milled and passed through a 200-mesh sieve; according to the molar ratio of Mg:(Al+Fe)=3:1, the magnesium oxide and red mud are evenly mixed, and roasted at 550°C for 4h. Obtain LDO, obtain the required adsorbent material through ball milling and passing through a 200-mesh sieve, which is denoted as adsorbent I.

Embodiment 2

[0030] The red mud is washed to neutral, dried, ball milled and passed through a 200-mesh sieve; according to the molar ratio of Mg:(Al+Fe)=3:1, the magnesium oxide and red mud are evenly mixed, and roasted at 550°C for 4h. Obtain LDO, through ball milling, pass 200 mesh sieves; Configure saturated sodium carbonate solution according to the mass ratio of LDO:sodium carbonate=3:1, put LDO into sodium carbonate solution, fully stir 10h, carbonate anion and free water Introduce its interlayer structure and synthesize LDH as another adsorbent material, denoted as Adsorbent II.

[0031] 2. Application of brilliant blue dye adsorption:

[0032] 1) Preparation of brilliant blue dye simulated wastewater:

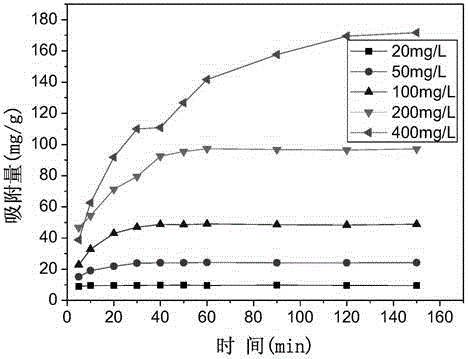

[0033] Weigh reactive brilliant blue dyes and dissolve them in a certain amount of water, prepare simulated wastewater with a concentration of 20, 50, 100, 200, and 400 mg / L, and weigh 50 ml of simulated wastewater for each set of samples.

[0034] 2) Preparation of contrast adsor...

Embodiment 3

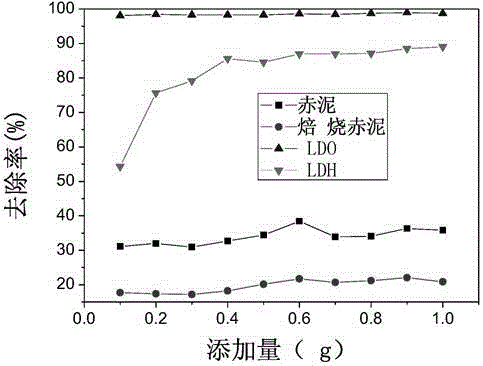

[0043] Add 0.1-1g of adsorbent II to 50mg / L brilliant blue dye, shake at 27°C for 120min, then take the supernatant and centrifuge at 4000rpm for 10min, and use UV-visible spectrophotometer to measure its Absorbance, and calculate its removal rate. With the increase of LDH addition, the removal rate of LDH to Brilliant Blue increased from 54.2% to 89.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com