Micro-stirring welding system and welding method integrating laser and mechanical dual sensors

A dual-sensor, welding system technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large welding deformation and troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

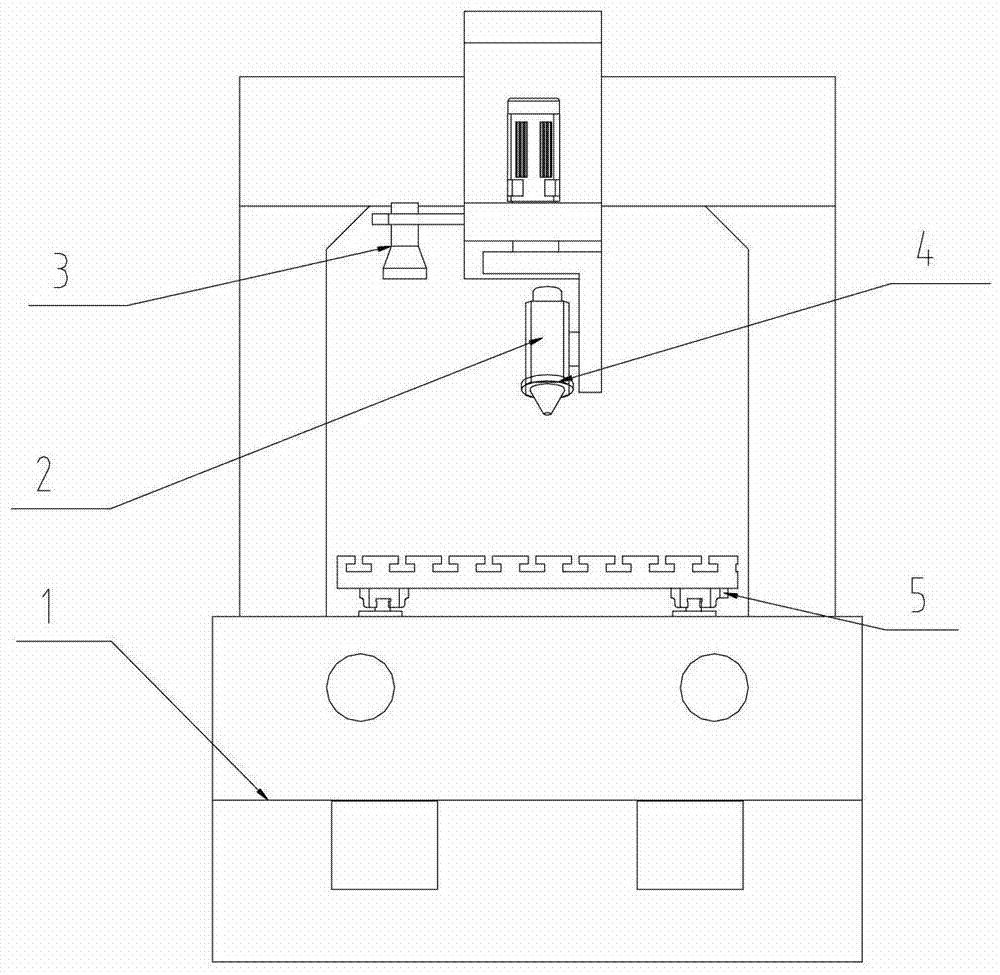

[0029] Such as figure 1 As shown, this embodiment includes: a five-axis machine tool platform 1, a welding spindle 2, a laser system 3, a mechanical sensor 4, a displacement sensor 5 and a control system, wherein the mechanical sensor 4 is installed on the welding spindle 2, and the displacement sensor 5 is installed on the Near the guide rail on the five-axis machine platform 1, the laser system 3 is installed on the five-axis machine platform 1, and the control system is respectively connected with the five-axis machine platform 1, the laser system 3, the force sensor 4, and the displacement sensor 5, and is used to control the Adjustment of axis machine tool platform 1, laser system 3, force sensor 4 and displacement sensor 5.

[0030] The five-axis machine tool platform 1 is a double-swing head mechanism with five-axis linkage in series, including X-axis, Y-axis, Z-axis, C-axis and S-axis. Among them, the X-axis, Y-axis, and Z-axis are moving axes, and the C-axis is rotati...

Embodiment 2

[0036] Embodiment 2 is a welding method using the micro-stirred welding system integrated with laser and mechanical dual sensors provided in Embodiment 1.

[0037] This embodiment includes the following steps:

[0038] The first step is to place the device to be welded on the five-axis machine tool platform, and after installation and fixation, control the movement of the X and Y axes through the control system to allow the laser sensor in the laser system to identify the starting point of the weld of the device to be welded;

[0039] In the second step, the laser system automatically identifies the welding seam of the device, and then saves the parameters of the welding seam track point into the corresponding database file;

[0040] In the third step, the staff writes the processing program in the control system and sets the welding process parameters;

[0041] The fourth step, after the above three steps are completed, press the welding start button in the control system, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com