Liquid crystal panel cutter and fixing device

A liquid crystal panel and fixing device technology, applied in glass cutting devices, conveyors, conveyor objects, etc., can solve problems such as high defective product rate, collision and scratches, etc., to improve product yield, avoid walking space, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

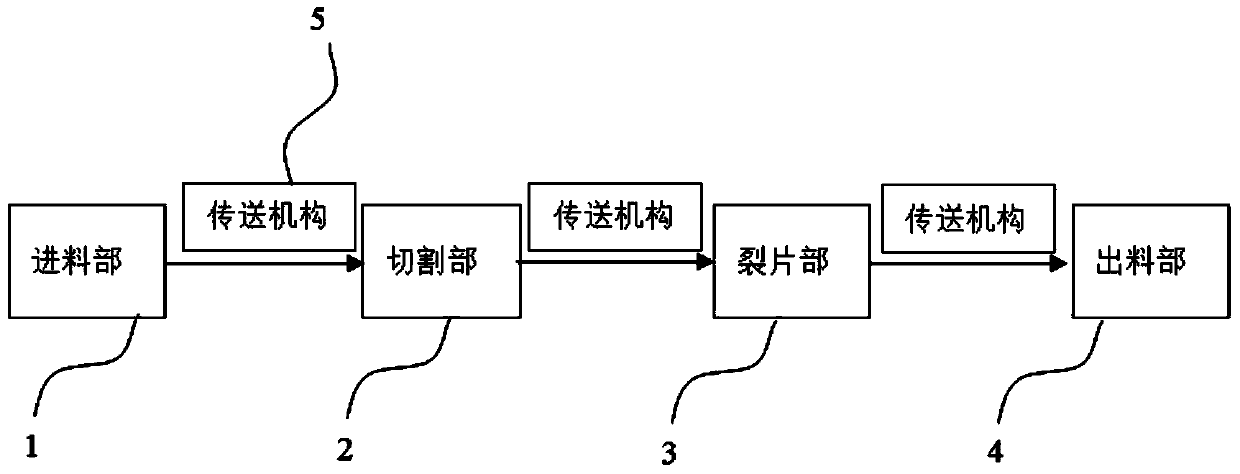

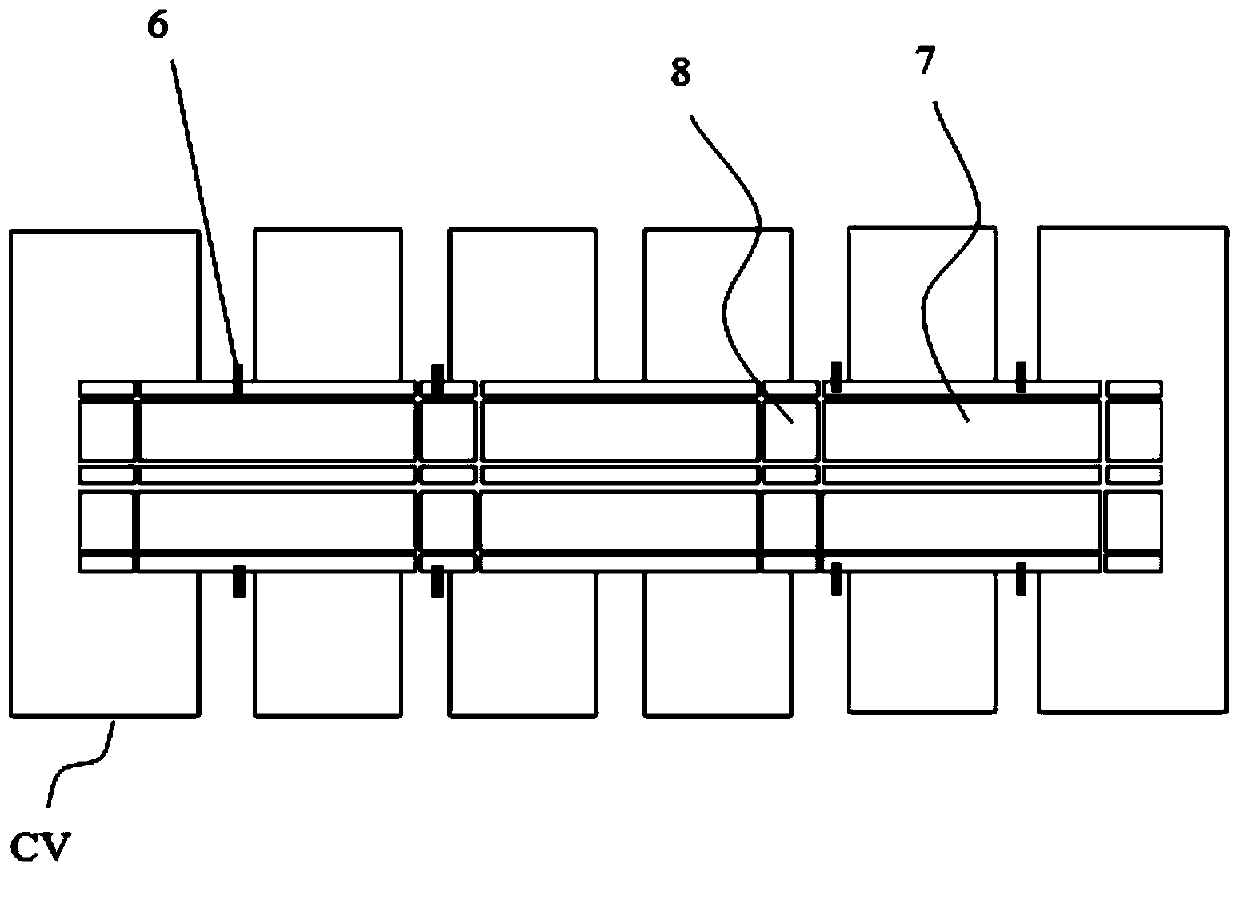

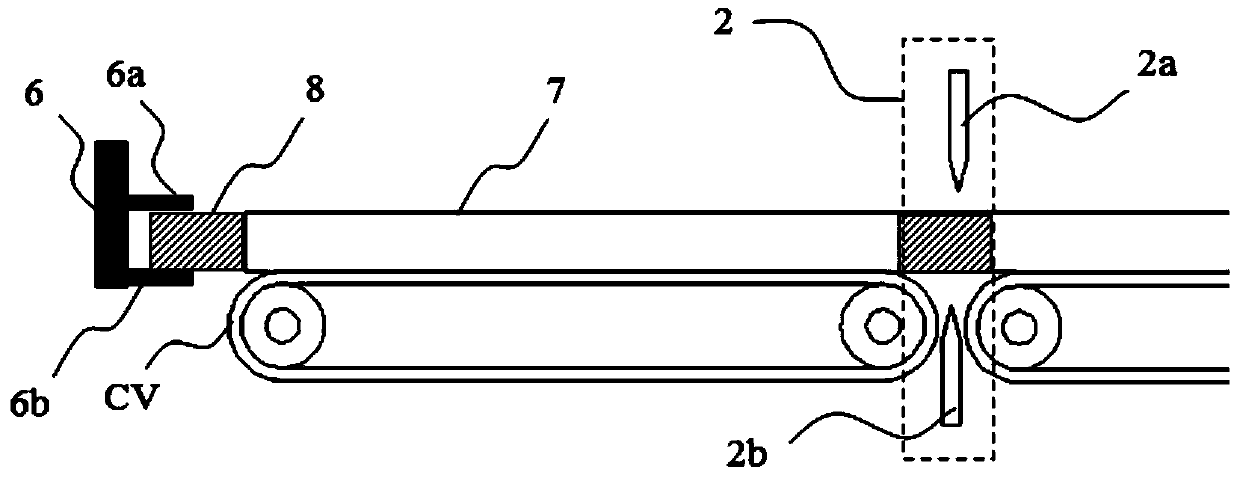

[0027] As mentioned above, the present invention provides a liquid crystal panel cutting machine for the defects of the prior art, including a cutting part, a split part, and a conveying mechanism for conveying liquid crystal panels, wherein the conveying mechanism includes a fully integrated A belt and a fixing device, the comprehensive integrated belt is used to carry and convey the liquid crystal panel, and the fixing device is used to fix the liquid crystal panel to prevent the liquid crystal panel from shaking during the cutting process and splitting process. The liquid crystal panel cutting machine provided by the invention can prevent the cut liquid crystal panel from colliding on the conveying mechanism, thereby improving the product yield and reducing the cost.

[0028] The present invention will be further described below with reference to the accompanying drawings.

[0029] refer to figure 1 , the same as the existing ones, the liquid crystal panel cutting machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com