A foam light soil high railway foundation

A technology of foam light soil and high-speed railway foundation, which is applied in the field of building construction, can solve problems affecting the smooth operation and safety of high-speed trains, reduce the service life of vehicles and track structures, and deteriorate train operating conditions, and achieve scientific and reasonable component ratios. The effect of maintenance cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The components for preparing high-speed rail-based foam lightweight soil are as follows:

[0025] (1) The cement is Jianpai Tower P.C32.5 composite Portland cement produced by Zhejiang Zhijiang Cement Co., Ltd. Main indicators: the initial setting time shall not be earlier than 45min, the final setting time shall not be later than 10h, the fineness, setting time, stability and strength shall meet the requirements of national standards; the cement density shall not be lower than 2700kg / m 3 .

[0026] (2) When the main raw materials enter the site, they must issue a factory certificate, and at the same time, they should be inspected according to the requirements in the table.

[0027]

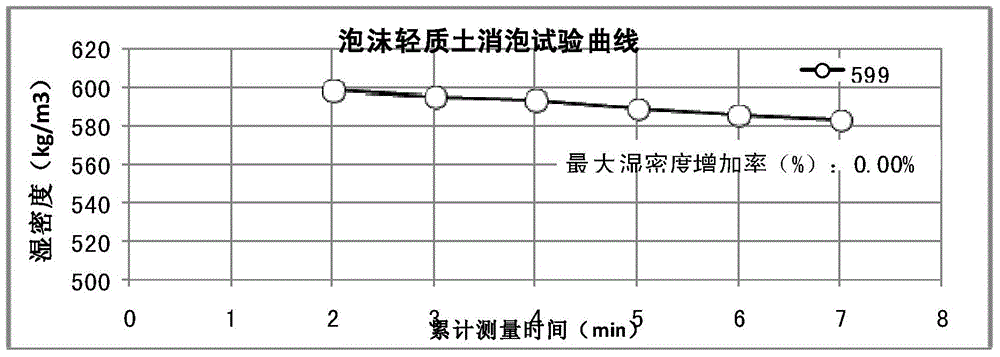

[0028] (3) The foaming agent used for foaming is the SRTJ-A foaming agent produced by Guangdong Shengrui Civil Engineering Technology Development Co., Ltd., which has the characteristics of low bleeding rate and low wet density increase rate, ensuring that the prepared foam The qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com