Ionic membrane electrolytic bath

An ionic membrane electrolytic cell and current collector technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of uneven current density distribution of electrolyte, uneven electrolyte concentration distribution, uneven current density distribution, etc. It can achieve the effect that the cell voltage drops significantly, the liquid concentration quickly tends to be uniform, and the current distribution is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

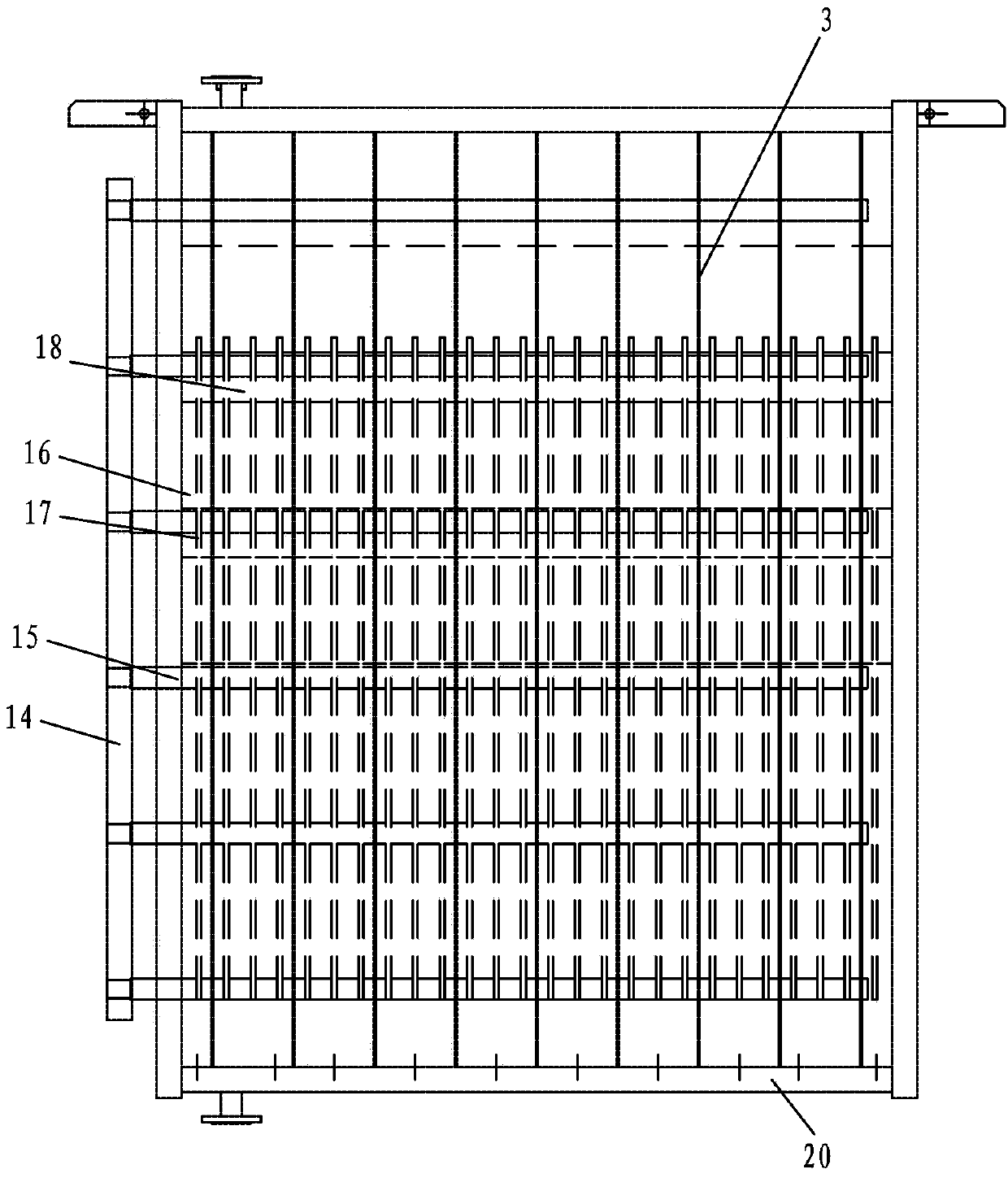

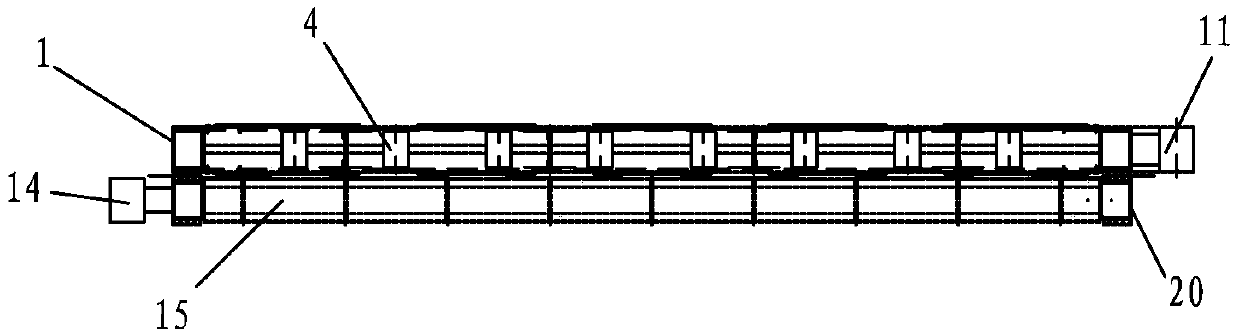

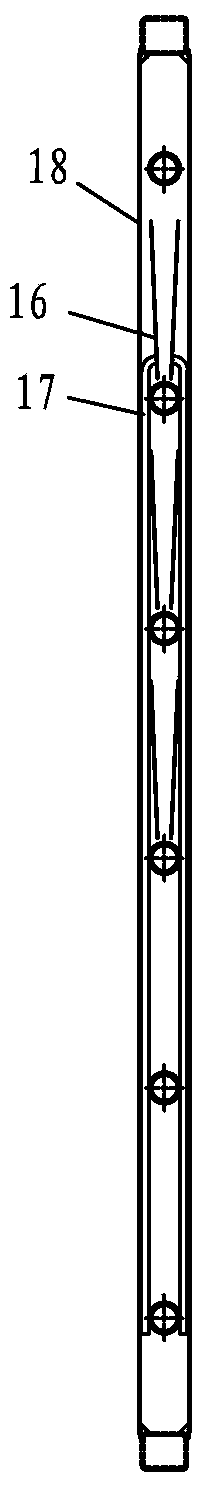

[0018] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the ionic membrane electrolyzer of the present invention includes more than one anode unit and more than one cathode unit, and the cathode unit and the anode unit are juxtaposed in the order of a cathode unit, an anode unit, another cathode unit, and another anode unit Adhere to the setting, figure 2 Only a cathode unit and an anode unit are schematically drawn, and each cathode unit includes a cathode frame 1 arranged along the left and right vertical directions, the bottom end of the cathode frame 1 is provided with an inlet, and the top end of the cathode frame 1 is provided with an outlet , the front and rear sides of each cathode frame 1 are respectively provided with a support plate 2 made of expanded mesh. The plates 3 are fixedly connected, and the side ends of the multi-channel cathode ribs 3 are respectively fixedly connected with the inner wall of the cathode frame 1 where they are located....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com