Beam formwork support device and method of use

A technology of supporting device and beam formwork, which is applied to the on-site preparation of formwork/formwork/work frame, pillar, and building components, etc., can solve the problems of material waste, low turnover, labor-consuming and time-consuming installation process, etc. The effect of construction speed, reduction of construction cost and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

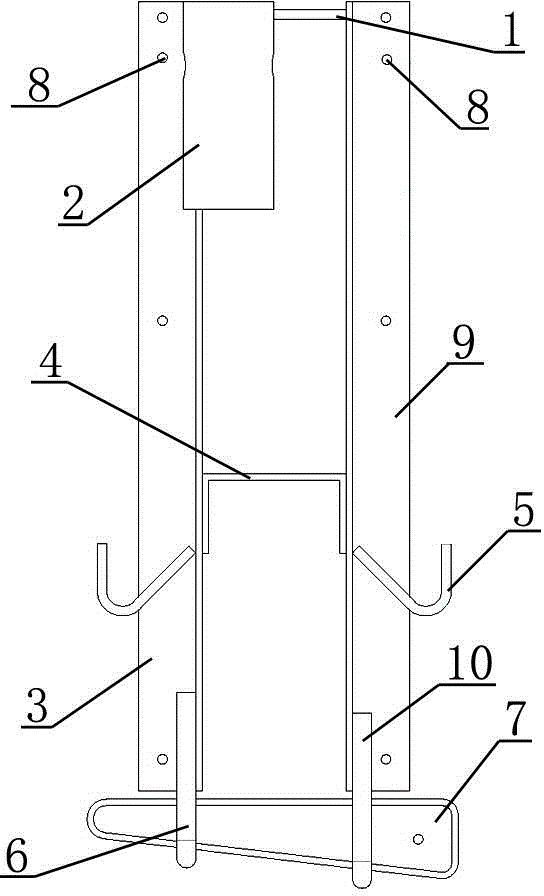

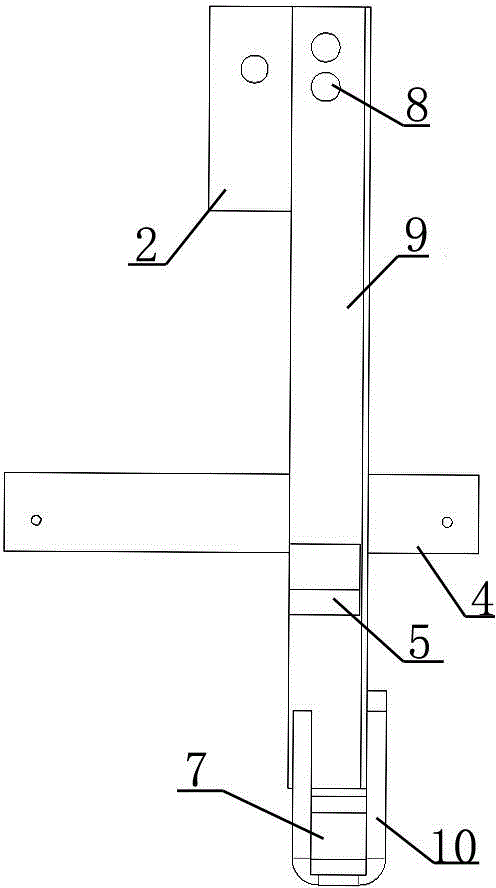

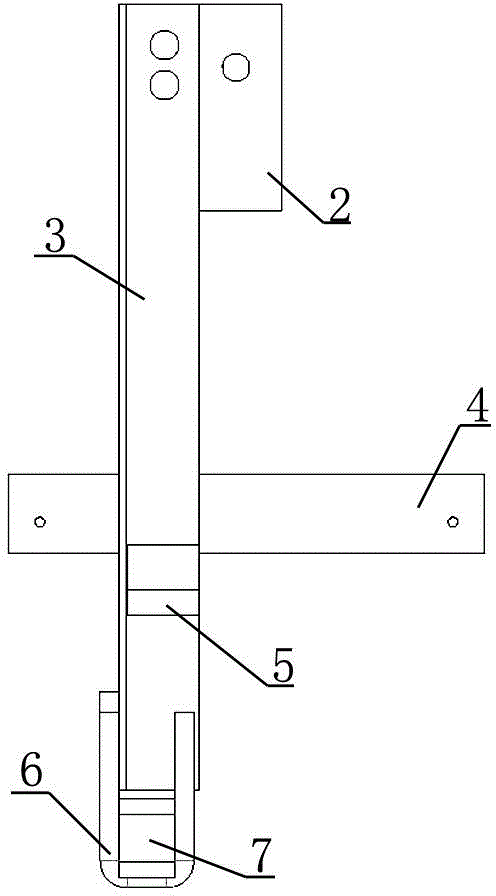

[0040] Examples see Figure 1 to Figure 4 As shown, a beam formwork supporting device includes a connecting plate 1, a supporting groove 4, a left U-shaped connecting card 6, a right U-shaped connecting card 10, a wedge-shaped pin 7, a left supporting angle steel 3 arranged in parallel and a right supporting The angle steel 9, the left support angle steel 3 and the right support angle steel 9 limbs are set opposite to each other, and a gap is reserved between the two;

[0041] The connecting plate 1 is supported between the top of the left supporting angle steel 3 and the top of the right supporting angle steel 9, and its end is welded and connected with the transverse limbs of the left supporting angle steel 3 and the right supporting angle steel 9, and the supporting groove 4 is parallel to the connecting plate 1 Setting, the setting position is the middle and lower part of the left support angle steel 3 and the right support angle steel 9, the outer surface of the support g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com