Waterproof and breathable electric appliance cavity structure and production method of waterproof and breathable film

A waterproof and breathable membrane, waterproof and breathable technology, applied in the direction of gas-proof/waterproof devices, components of lighting devices, lighting devices, etc., can solve the problems of insufficient internal and external air pressure balance, large thermal expansion effect of gas, and inability to pass through, etc., to achieve The pore size of the diaphragm is easy to control, the pore density is uniform, and the production speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

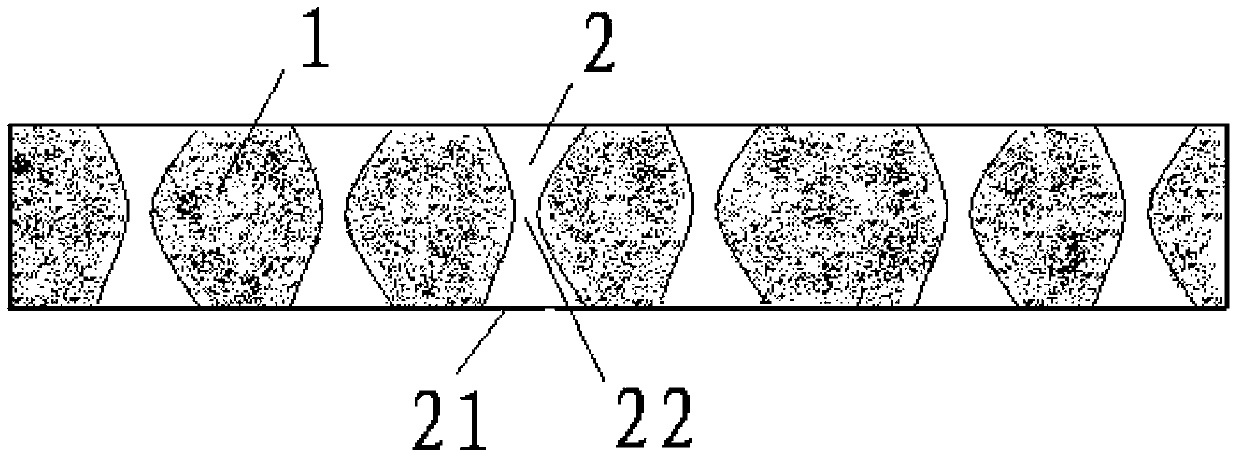

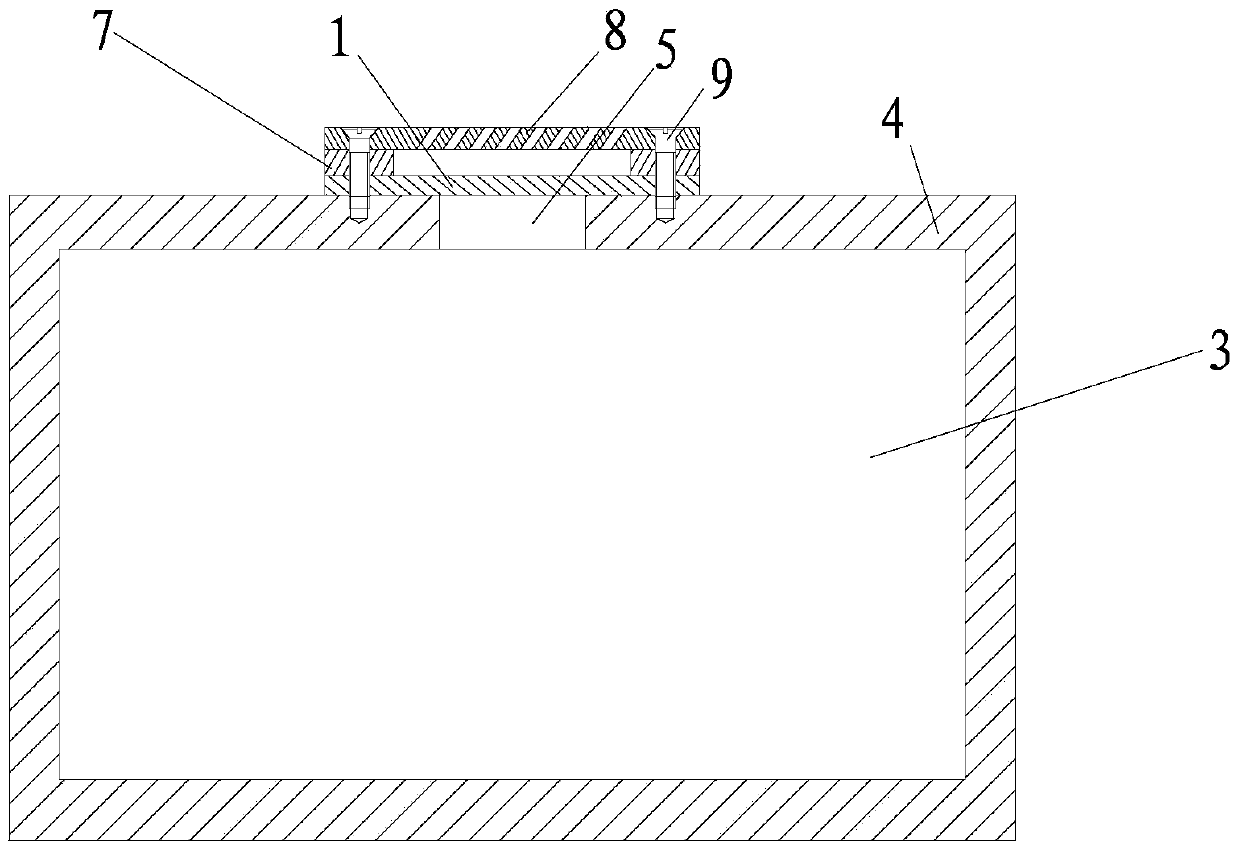

[0032] A method for producing a waterproof breathable film, comprising the following steps:

[0033] A. Using the PET polymer material film as the base material, the polymer material film is irradiated with high-energy charged particles.

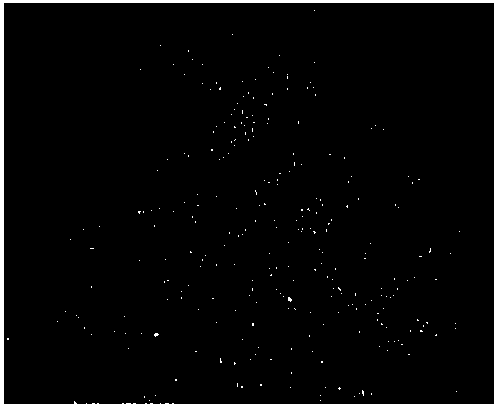

[0034] The irradiation power is 2,000-10,000 kilowatts, and the irradiation time is 0.5-200 seconds. The micropore density can be adjusted by adjusting the irradiation energy and irradiation time, and the obtained micropore density ranges from 100,000 to 20 million per square centimeter.

[0035] B. Immerse the irradiated PET polymer material film in a container filled with NaOH solution for etching reaction to obtain a waterproof and breathable film.

[0036] The concentration of NaOH solution is 15-35%, the etching reaction temperature is 70-90 degrees Celsius, the etching time is 0.2-60 minutes, and the obtained micropore diameter is 30 nanometers, which can be adjusted by adjusting the alkali concentration, reaction temperature, and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com