Measurement device, with step-shaped cone, absorbing all energy of high-energy laser

A high-energy laser and energy measurement technology, applied in measurement devices, optical radiation measurement, photometry, etc., can solve the problems of low laser damage threshold and low temperature measurement accuracy, and achieve the effect of reducing power density and increasing heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

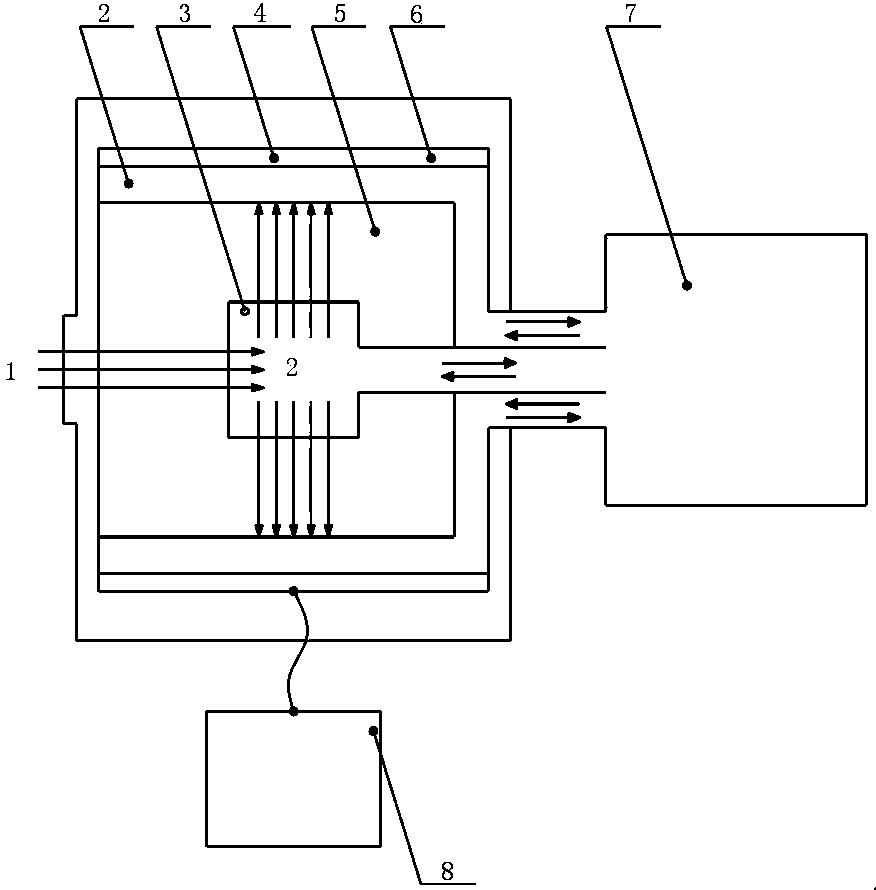

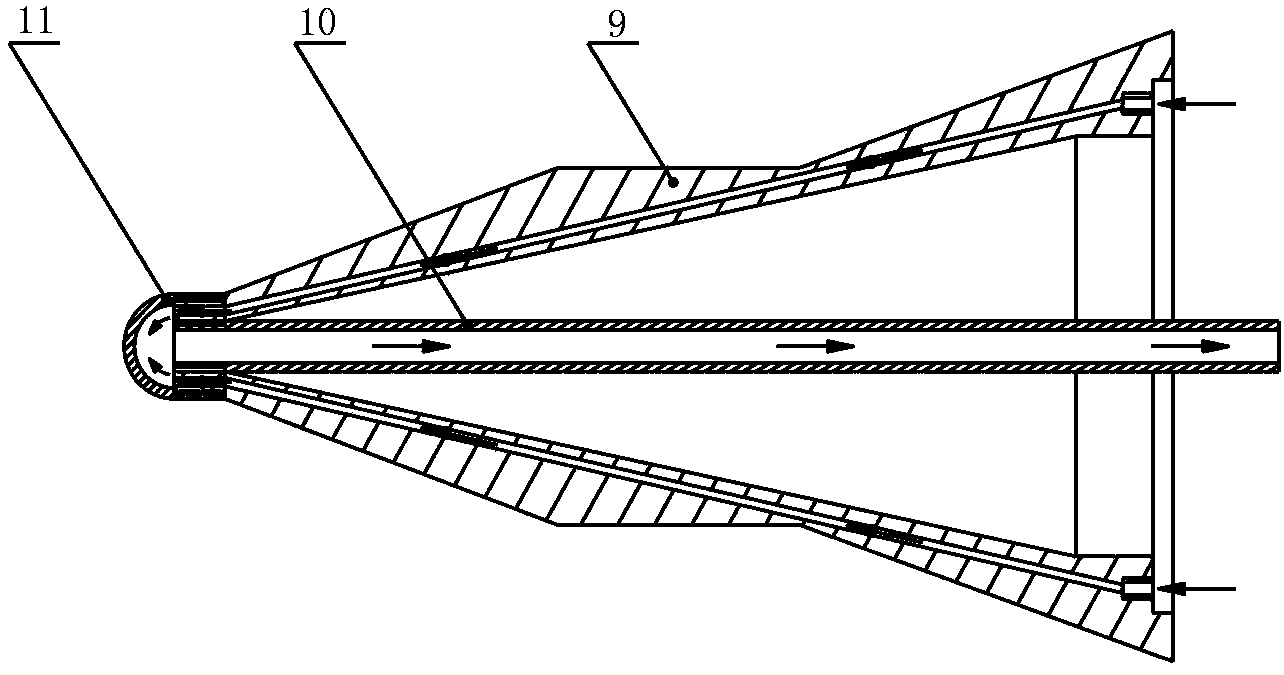

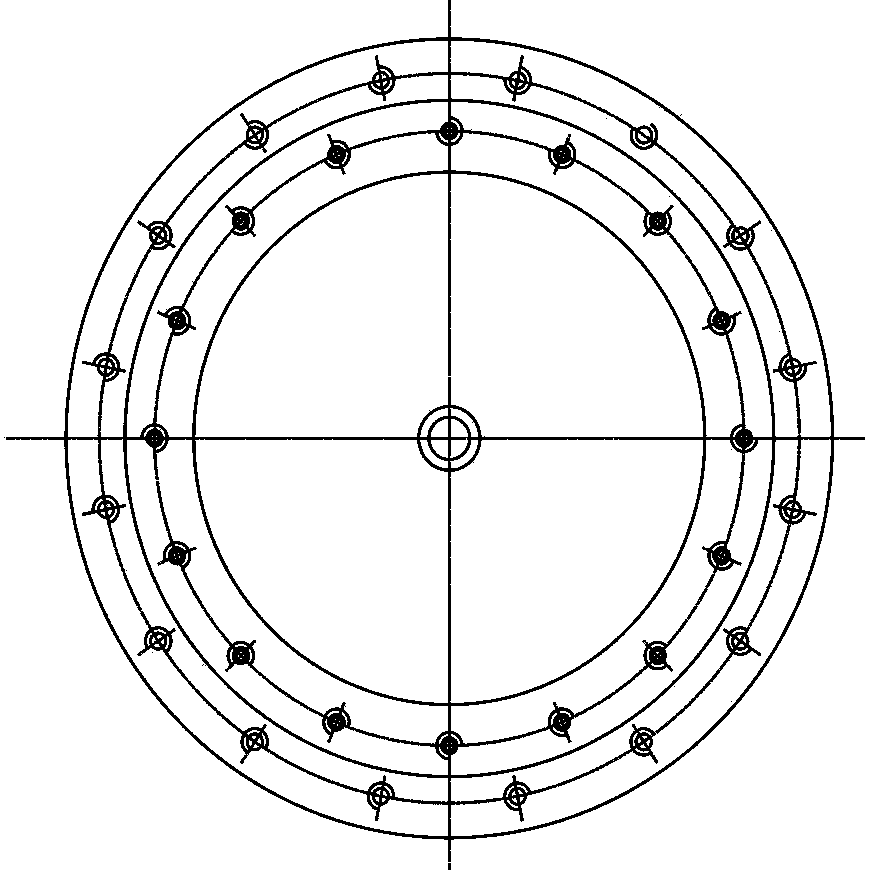

[0031] figure 1 It is a schematic diagram of the structure of the stepped cone high-energy laser total absorption energy measurement device, where the thin arrow marks the propagation direction of the laser light, and the thick arrow marks the water flow direction. figure 1 The medium laser enters the absorption cavity 5 from the entrance 1 of the energy meter, and is incident on the reflector 3. The stepped reflection cone 9 is sandblasted and gold-plated to form a diffuse reflection surface. The laser diffusely reflects to the entire absorption cavity 5 through the reflector 3. The absorber 2 and the heat insulator 4 form a closed absorption cavity 5, and the laser light is fully absorbed by the absorption cavity 5. The bottom of the water tank in the water circulation part 7 is provided with a submersible pump, which can pump water into the pipeline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com