Refractive index matching liquid

A refractive index matching liquid and refractive index technology, which is applied in the direction of testing optical performance, phase influence characteristic measurement, etc., can solve the problems of high price, complex composition, high cost of use, etc., and achieve the effect of simple production, small fluidity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation of the refractive index matching liquid is as follows: mixing glycerol and a surfactant in parts by weight, and stirring at normal temperature until it is transparent without flocs, and thus the refractive index matching liquid is obtained. The preparation also includes the step of defoaming the obtained refractive index matching liquid. The defoaming treatment may adopt the following method: the obtained refractive index matching liquid is placed in a vacuum container and vacuumized to remove air bubbles. In the defoaming treatment, the obtained refractive index matching liquid can also be left to stand until the air bubbles dissipate, and the standing time is determined according to the actual time for the air bubbles to dissipate. The defoaming treatment can be carried out after the refractive index matching liquid is prepared, and can also be carried out before the refractive index matching liquid is used.

[0027] Further, the refractive index matc...

Embodiment 1-14

[0033] The raw materials were taken according to the parts by weight listed in Table 1 to prepare a refractive index matching liquid, and the refractive index of the refractive index matching liquid was measured at 25° C. at a wavelength of 1550 nm.

[0034] Table 1. The parts by weight of each raw material of Examples 1-14 and the refractive index of the obtained refractive index matching liquid

[0035]

[0036]

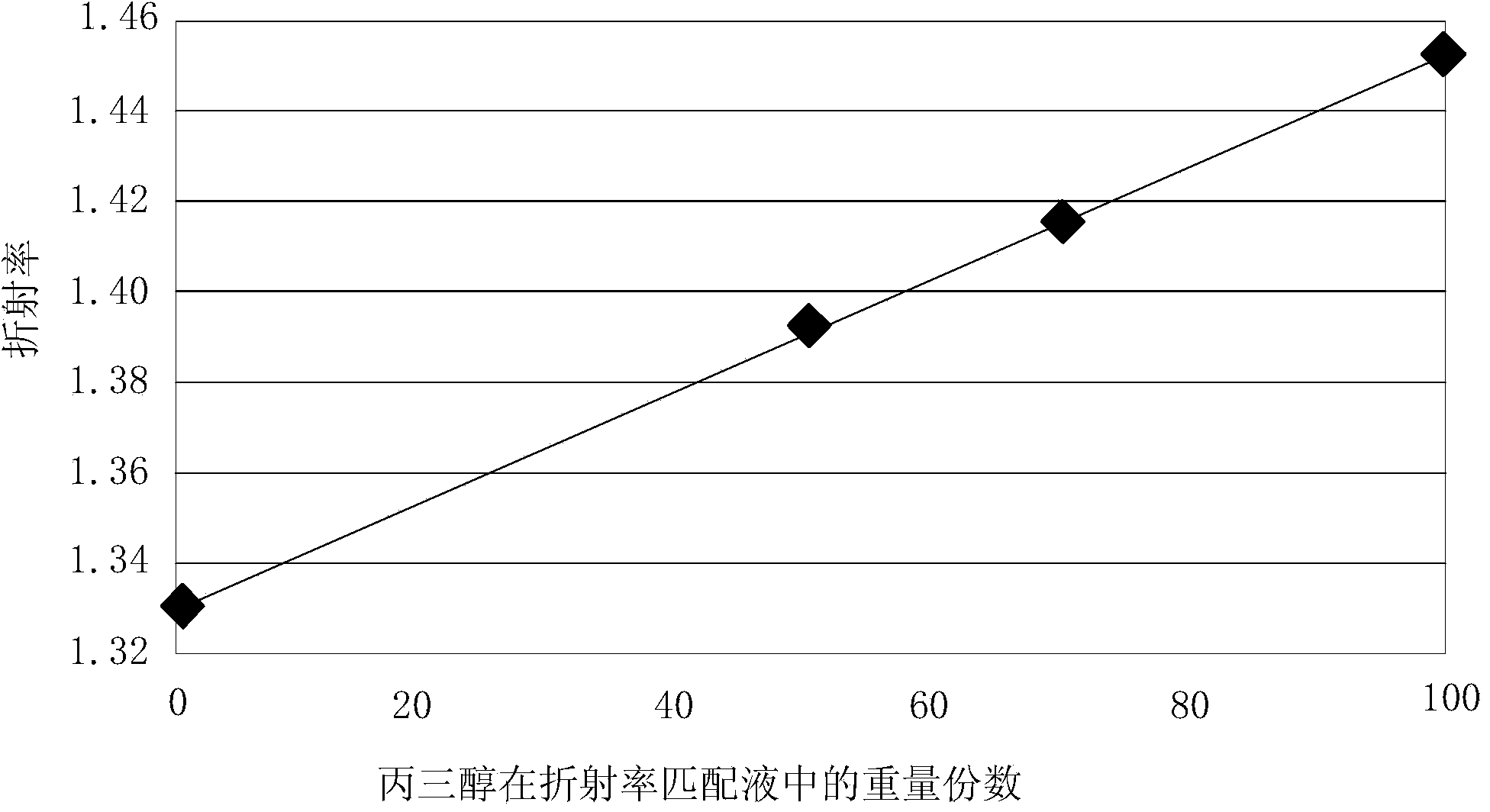

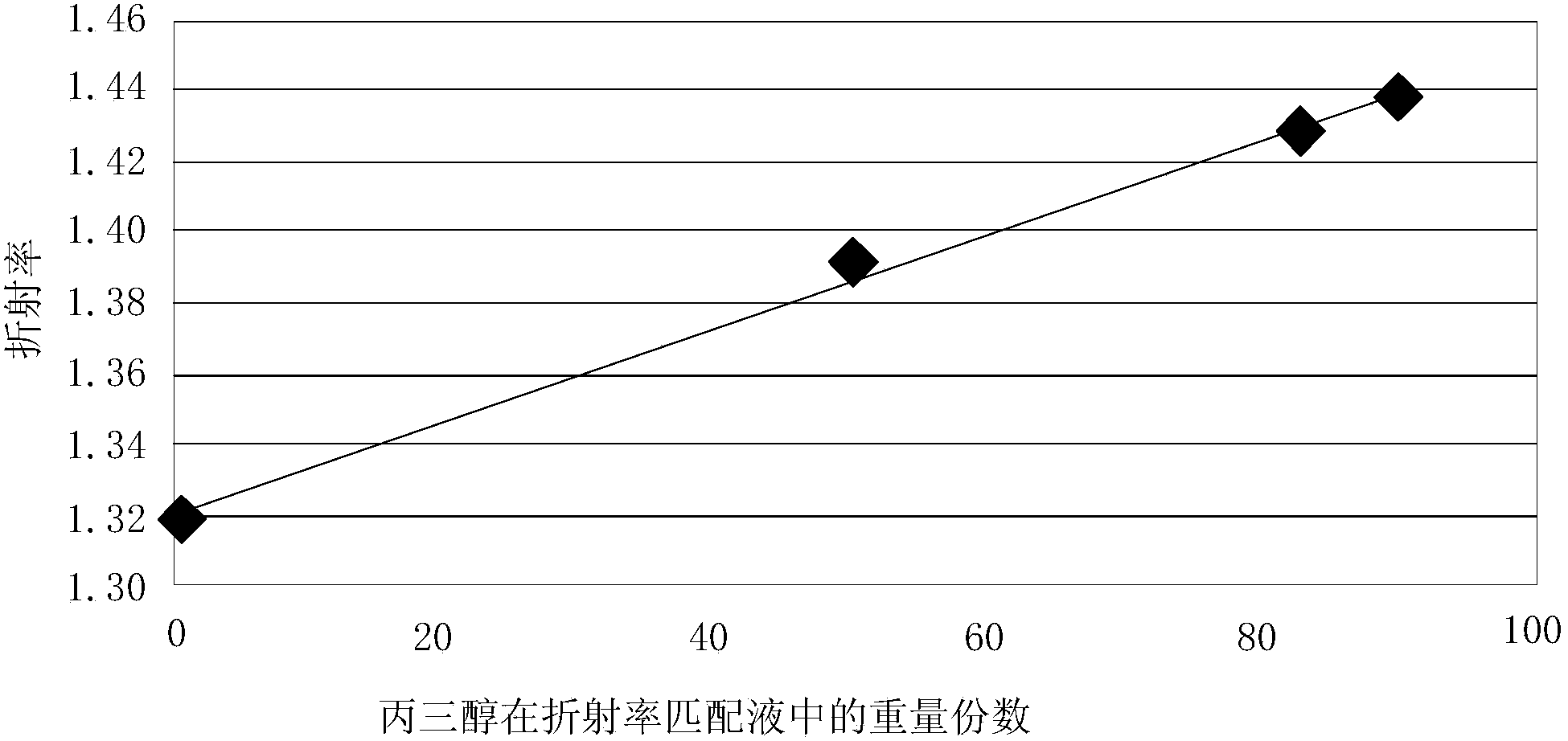

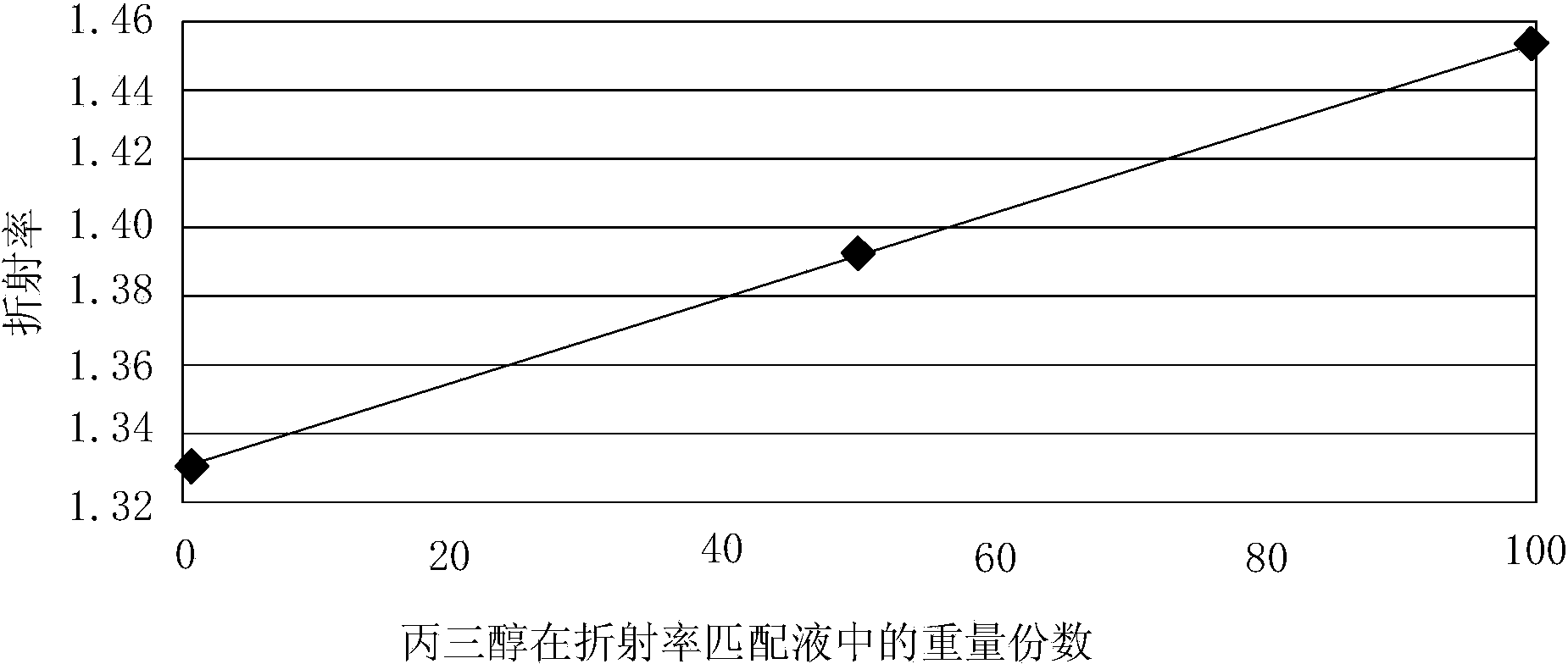

[0037] The refractive index curve of the refractive index matching liquid that embodiment 1-4 obtains is as follows figure 1 As shown, where linear fitting is used: y=0.123x+1.329, R 2 =0.999; the refractive index curve of the refractive index matching liquid that embodiment 5-8 obtains is as follows figure 2 As shown, where linear fitting is used: y=0.134x+1.318, R 2 =0.996; the refractive index curve of the refractive index matching liquid that embodiment 9-11 obtains is as follows image 3 As shown, where linear fitting is used: y=0.123x+1.329, R 2 =0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com