Test auxiliary device for testing tensile strength of rock through Brazilian test

A technology of tensile strength and auxiliary devices, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., can solve problems affecting test accuracy, complex fixture structure, and poor results, etc., to achieve Accurate test data, convenient disassembly and assembly, and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

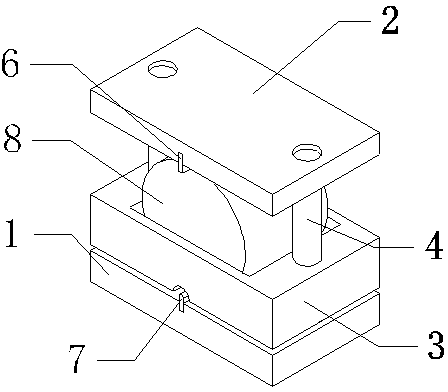

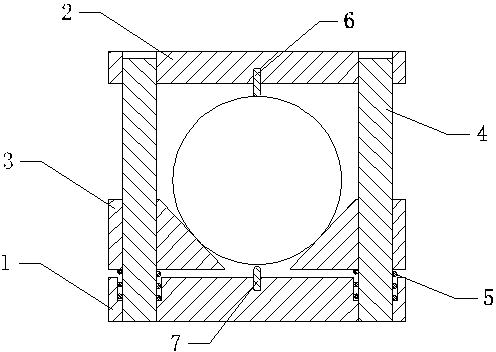

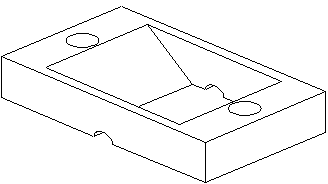

[0019] Such as Figure 1-3 Shown is a specific embodiment of the present invention, this is used for the test auxiliary device of Brazilian method testing rock tensile strength, comprises base 1, spacer 2, upper spacer 6 and lower spacer 7, column 4, positioning frame 3 and spring 5.

[0020] Described column 4 is provided with two, and is symmetrically fixed on the middle position of both ends of base 1, and spring 5 is sleeved on described two column 4 respectively, in order to ensure the stability of spring 5, described base 1 is provided with Two spring slots, the column 4 passes through the spring slot and is fixed in the base 1. In this embodiment, the column 4 is fixed by welding, and the spring 5 passes through the column 4 and is arranged in the spring slot.

[0021] The internal space of the positioning frame 3 is set as a trapezoidal hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com