Charging device for high-power power battery pack

A technology for power battery packs and charging devices, applied in battery circuit devices, circuit devices, collectors, etc., can solve problems such as output power limitation, unbalanced power consumption, unscientific charging current, etc., to ensure balance and stability, The effect of increasing the charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

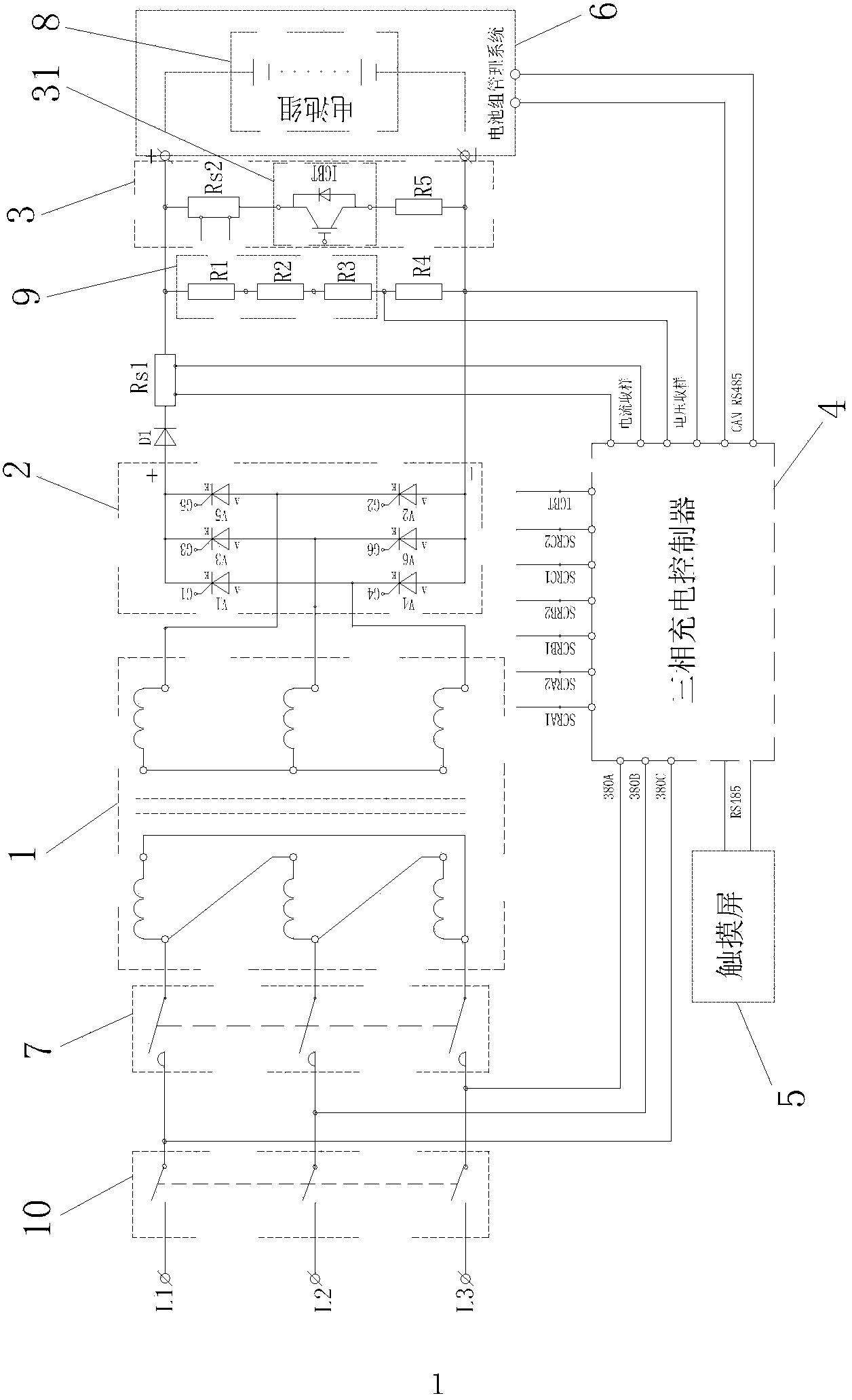

[0028] figure 1 As shown, a charging device for a high-power power battery pack includes a three-phase transformer 1, a three-phase thyristor phase-shifting voltage regulation rectifier circuit 2, an IGBT negative pulse discharge circuit 3, a three-phase charging controller 4, a touch screen 5, A battery pack management system 6, the touch screen 5 is connected to the three-phase charging controller 4 through the RS485 communication interface;

[0029] The primary coil of the three-phase transformer 1 is connected to the three-phase power supply through the contactor 7, and the three-phase thyristor phase-shift voltage regulation rectifier circuit 2 includes six thyristors, and the positive pole of the first thyristor V1 is connected to the fourth thyristor. The negative pole of the thyristor V4 is connected to the first end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com