Adhesive sheet

A technology of adhesive sheets and adhesives, applied in the direction of polyether adhesives, conductive adhesives, adhesive types, etc., can solve problems such as adverse effects and pollution of optical properties of optical components, and achieve low pollution, Improved inspection accuracy and reduced appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

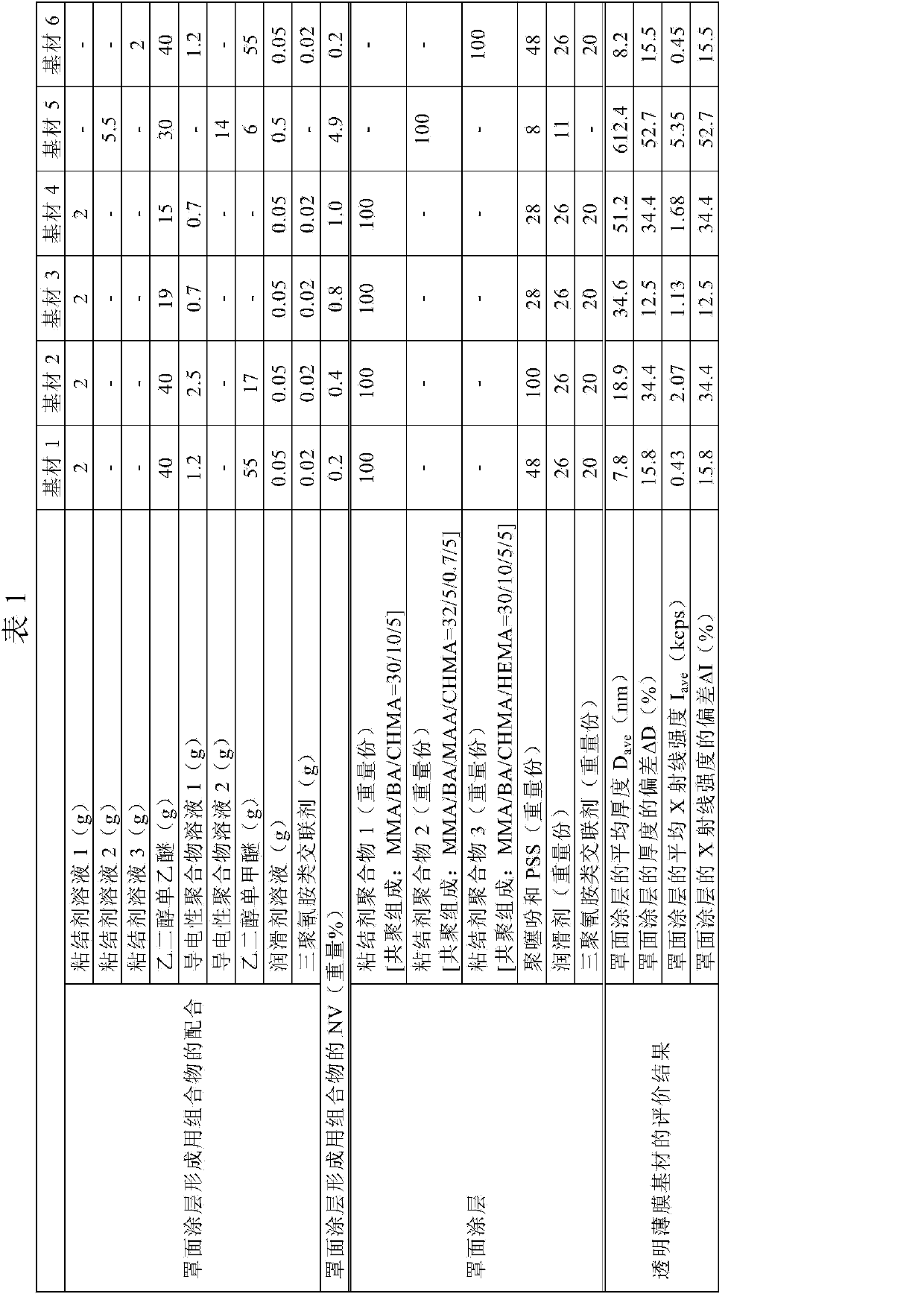

[0271] Manufacturing example 1 [Manufacturing example of transparent film substrate]

[0272] (Preparation of a composition for forming a top coat layer)

[0273] Charge 25g of toluene into the reactor, raise the temperature inside the reactor to 105°C, then add 30g of methyl methacrylate (MMA) and 10g of n-butyl acrylate (BA) dropwise to the above reactor continuously in 2 hours. ), 5g cyclohexyl methacrylate (CHMA), 0.2g azobisisobutyronitrile mixed solution. After completion of the dropwise addition, the temperature in the reactor was adjusted to 110 to 115°C, and the same temperature was maintained for 3 hours to carry out a copolymerization reaction. After 3 hours, a mixed solution of 4 g of toluene and 0.1 g of azobisisobutyronitrile was dropped into the reactor, and the same temperature was maintained for 1 hour. Then, the temperature in the reactor was cooled to 90°C, and toluene was added to adjust the NV to 5% by weight, and an acrylic polymer containing 5% by weig...

manufacture example 2

[0277] Manufacturing example 2 [Manufacturing example of transparent film substrate]

[0278]In Production Example 1, the amount of conductive polymer solution 1 used was changed from 1.2 g to 2.5 g, and the amount of ethylene glycol monomethyl ether used was changed from 55 g to 17 g. In addition, the solution for forming a top coat layer was applied so that the thickness after drying was about 20 nm. Otherwise, it carried out similarly to Production Example 1, and produced the transparent film base material (it may also be called "substrate 2") which has a transparent top coat layer on one side of a PET film.

manufacture example 3

[0279] Manufacturing example 3 [Manufacturing example of transparent film substrate]

[0280] In Production Example 1, the amount of ethylene glycol monoethyl ether used was changed from 40 g to 19 g, the amount of conductive polymer solution 1 used was changed from 1.2 g to 0.7 g, and ethylene glycol monomethyl ether was not used. In addition, the solution for forming a top coat layer was applied so that the thickness after drying was about 40 nm. Otherwise, it carried out similarly to the manufacture example 1, and produced the transparent film base material (it may also be called "substrate 3") which has a transparent top coat layer on one side of a PET film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com