Shovel plate with biomimetic geometrical structure characteristics for micro-appearance processing on surface of soil

A soil surface and geometric structure technology, which is applied in the fields of application, tillage implements, agricultural machinery and implements, etc., can solve the problems of weakening the micro-topography processing effect of the soil surface, unsuitable soil conditions for farming, and easy bending and deformation of shovel plates. Achieve effective soil surface micro-topography processing operations, increase soil water storage and moisture conservation capacity, and prevent soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

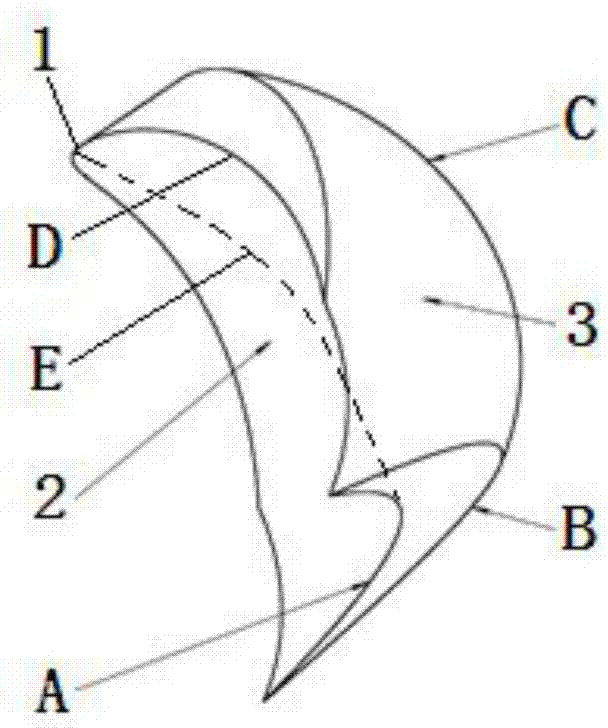

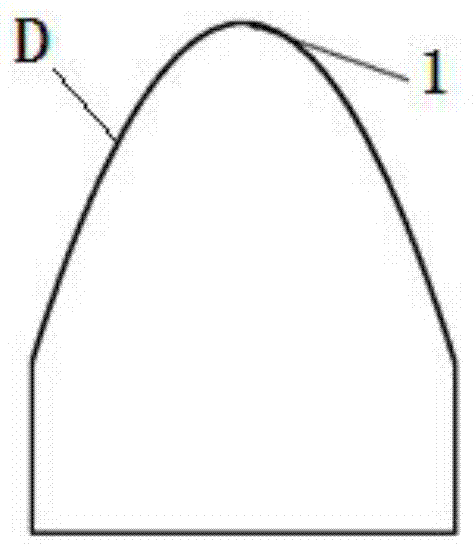

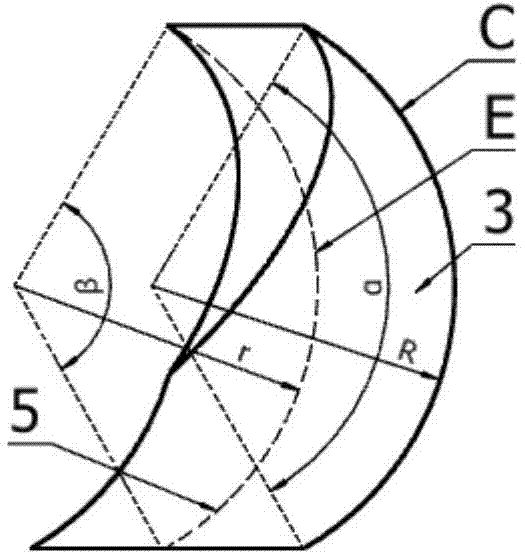

[0037] The specific structure of the shovel plate with bionic geometric structure characteristics for machining rolling parts of soil surface microtopography is given by Figure 1 to Figure 4 show. The characteristics of the shovel with bionic geometric structure characteristics in this example are: the cross-sectional contour curve B of the back soil surface of the bionic shovel takes the vertex of the curve as the origin, and the characteristic curve equation is y=ax 2 , where the value of the parameter a is 0.025; the curve segment whose x interval is between -50mm and 50mm is used. The cross-sectional contour curve A of the bionic shovel and the cross-sectional contour curve B of the back soil surface are in the same coordinate system, and the curve equation is y=bx 2 +c, where the value of parameter b is 0.0125, and the value of parameter c is 40; the x interval of the curve segment used is -50mm to 50mm. The contour curve E of the longitudinal section of the facing soi...

Embodiment 2

[0041] The second structure of the shovel plate with bionic geometric structure characteristics for machining rolling parts of soil surface microtopography is composed of Figure 11 show. The difference from Example 1 is that the shovel with bionic geometric structure features in this example has the following characteristics: the cross-sectional contour curve B of the back soil surface of the bionic shovel takes the vertex of the curve as the origin, and the characteristic curve equation is y=0.02 x 2 , the x interval of the curve segment used is -80mm to 80mm. The cross-sectional contour curve A of the bionic shovel is in the same coordinate system as the cross-sectional contour curve B of the back soil surface, and the curve equation is y=0.01x 2 +64, the x interval of the curve segment used is -80mm to 80mm. The profile curve E of the longitudinal section on the soil-facing surface is represented by a circular arc. The arc radius r of the profile curve of the longitudin...

Embodiment 3

[0043] The third structure of the shovel plate with bionic geometric structure characteristics for machining rolling parts of soil surface microtopography is composed of Figure 12 show. Different from Embodiment 1 and Embodiment 2, the profile curve A of the cross-section profile of the blade facing the soil and the profile curve B of the cross-section of the soil-back surface of the shovel with bionic geometric structure features have the same curvature. This embodiment has the following characteristics: the cross-sectional profile curve B of the back soil surface of the bionic shovel is based on the apex of the curve as the origin, and the characteristic curve equation is y=0.15x 2 , the interval of x of the curve segment used is -40mm to 40mm. The cross-sectional contour curve A of the bionic shovel and the cross-sectional contour curve B of the back soil surface are in the same coordinate system, and the curve equation is y=0.15x 2 +10, the x interval of the curve segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com