Dust collector for energy-saving environment-friendly axial flow fan group

An energy-saving and environmental protection, dust removal device technology, applied in the direction of dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems that the dust removal device cannot achieve the dust removal effect, cannot reach the ecological city, and increase equipment investment. Achieve the effect of reducing power, saving resources and energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

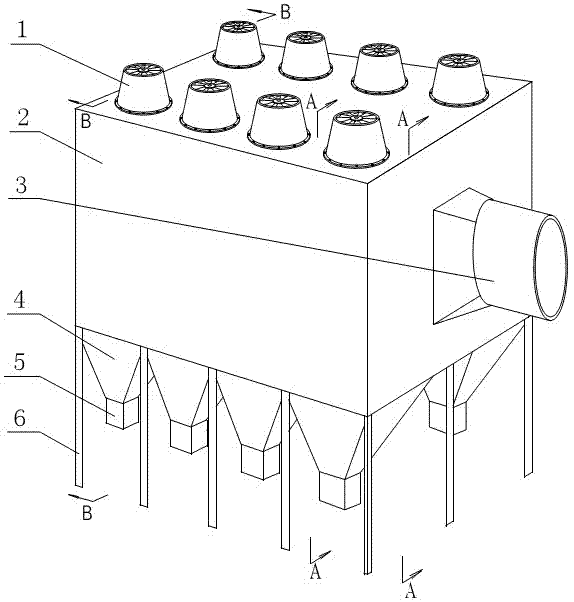

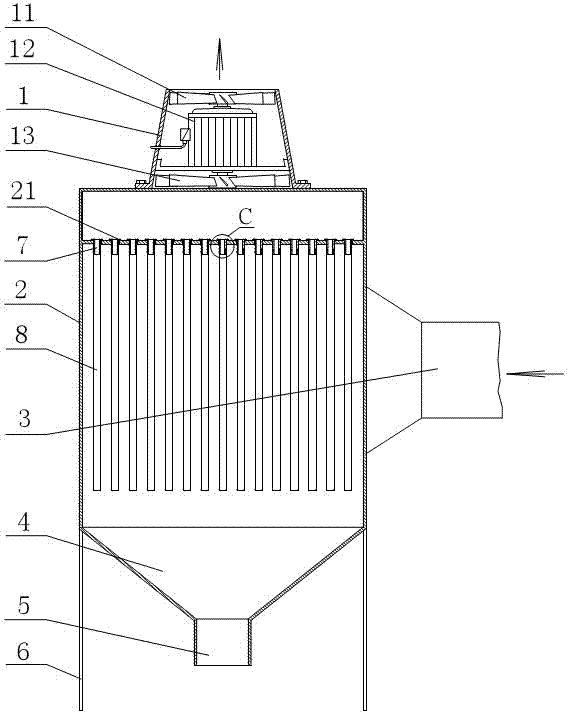

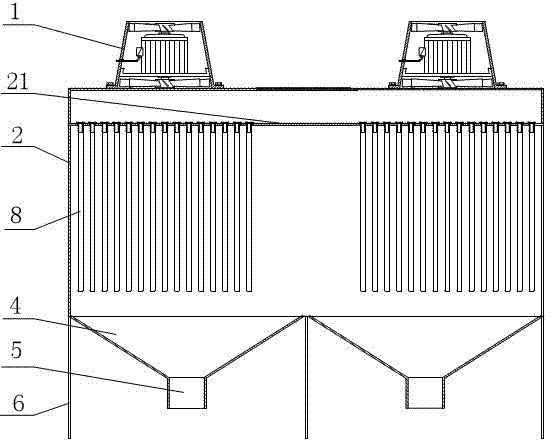

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] The box body 2 is a complete large cavity, which is simple in structure and easy to manufacture and process. Above the partition is a clean room and an exhaust duct, and below the partition is a dust removal room. The box is fixed on the ground through the support frames 6 at its lower end. superior.

[0013] There are eight air outlets evenly distributed on the upper surface of the box, and a fan is fixed with screws at each air outlet. On the side wall of the box 2, an air inlet pipe 3 is welded and fixed between the two symmetrical air outlets. It directly leads into the large cavity of the box body 2, and welds and fixes a partition plate 21 with a through hole at a distance of 1 to 3 meters from the top of the box body. A filter bag ring 7 is installed at the through hole of the partition plate corresponding to each fan. The port has a flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com