Epoxy resin vacuum pouring mechanical arm

A technology of vacuum casting and epoxy resin, which is applied in the field of epoxy resin casting, which can solve the problems of large volume of pouring box, low work efficiency, waste of materials, etc., and achieve the effect of small volume of vacuum box, high work efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

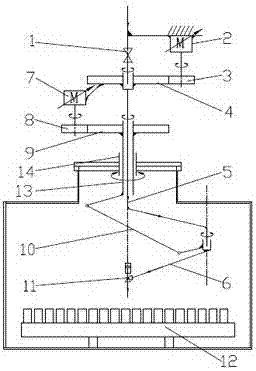

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

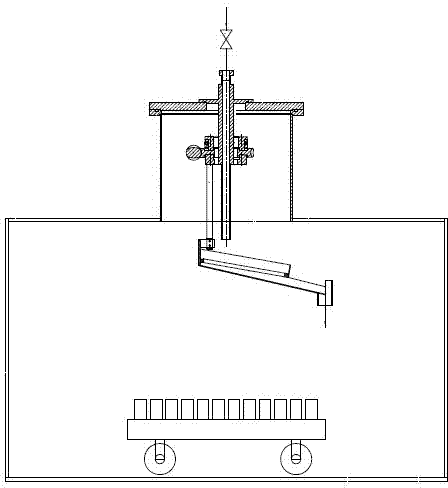

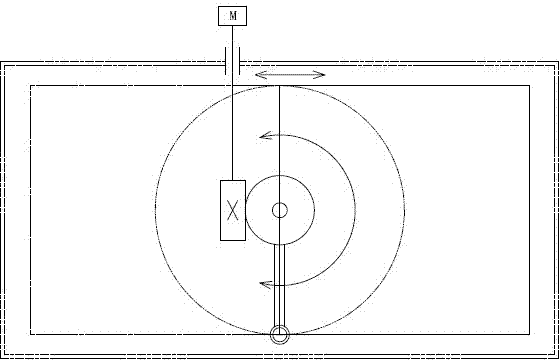

[0029] image 3 , Figure 4 , Figure 5 An epoxy resin vacuum casting mechanical arm is shown, including a feed valve 1, a feed pipe, a spindle drive servo reduction motor 2, a spindle drive pinion 3, a spindle gear 4, a pouring main arm 5, a pouring forearm 6, and a forearm Swing drive servo deceleration motor 7, forearm drive pinion 8, forearm swing gear 9, forearm swing push rod 10, pouring angle valve 11, shaft sleeve 13 and sealing chamber 14, feed valve 1 is at one end of feed pipe, feed The feeding tube passes through the main shaft gear 4, the feeding tube is connected to the casting main arm 5 through the rotary joint, the casting main arm 5 passes through the forearm swinging gear 9 and is fixed on the vacuum sealed box through the sealing chamber 14 and the shaft sleeve 13, and the casting The main arm 5 is connected to the castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com