Polysilicon Deposition Device

A deposition device, polysilicon technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of reducing polysilicon production output, quality decline, process cycle time increase, etc., to shorten equipment cleaning or cleaning time, improve product quality Yield, the effect of shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

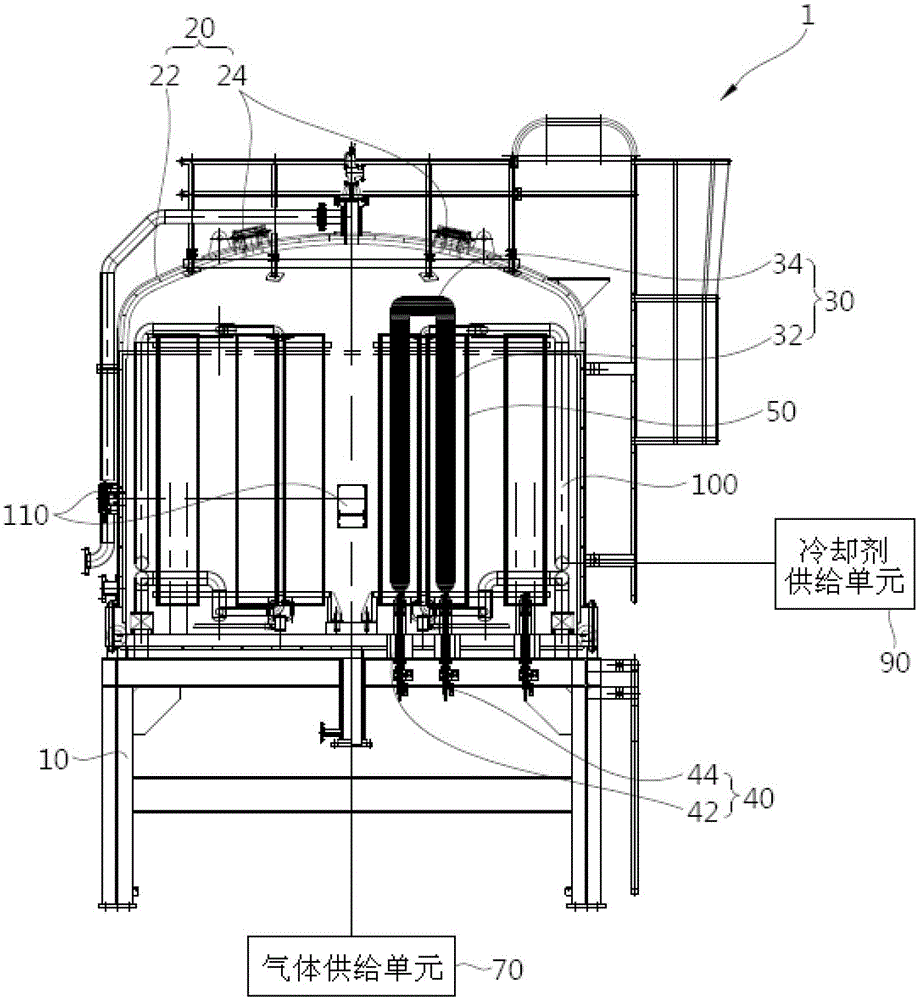

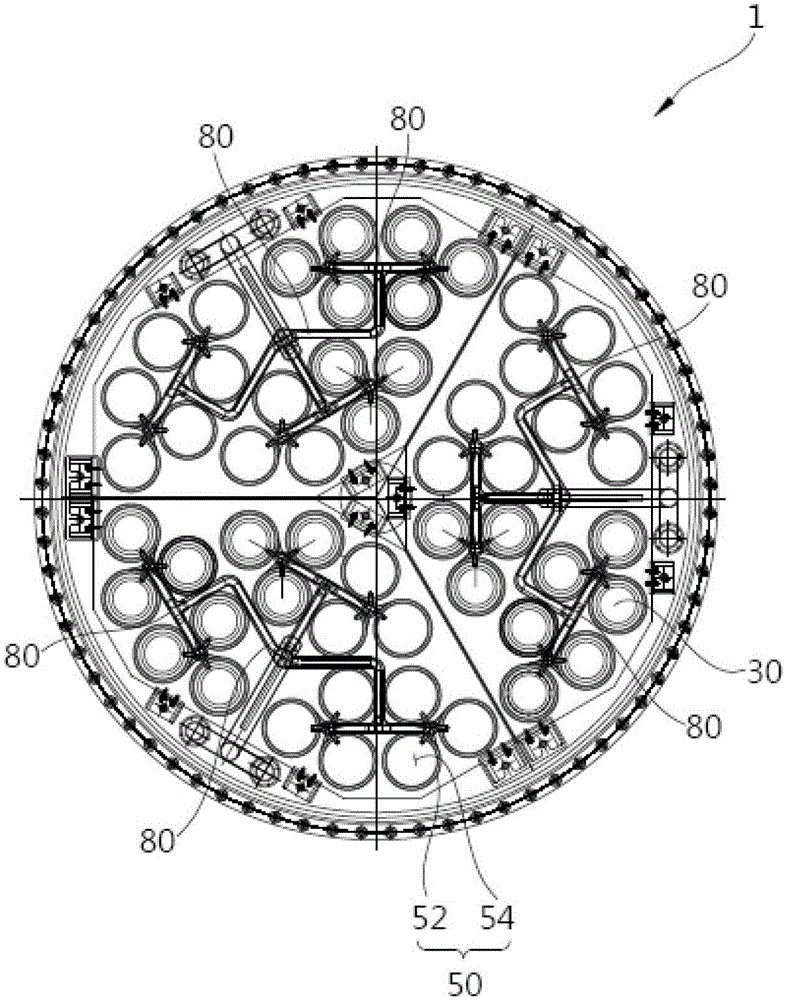

[0069] figure 1 is a cross-sectional view of a polysilicon deposition apparatus according to an embodiment of the present invention, figure 2 It is a plan view of the polysilicon deposition apparatus according to the embodiment of the present invention.

[0070] like figure 1 and figure 2 As shown, the polysilicon deposition apparatus 1 according to the first embodiment of the present invention includes a reaction chamber 20 , a silicon core rod 30 and a jacket unit 50 .

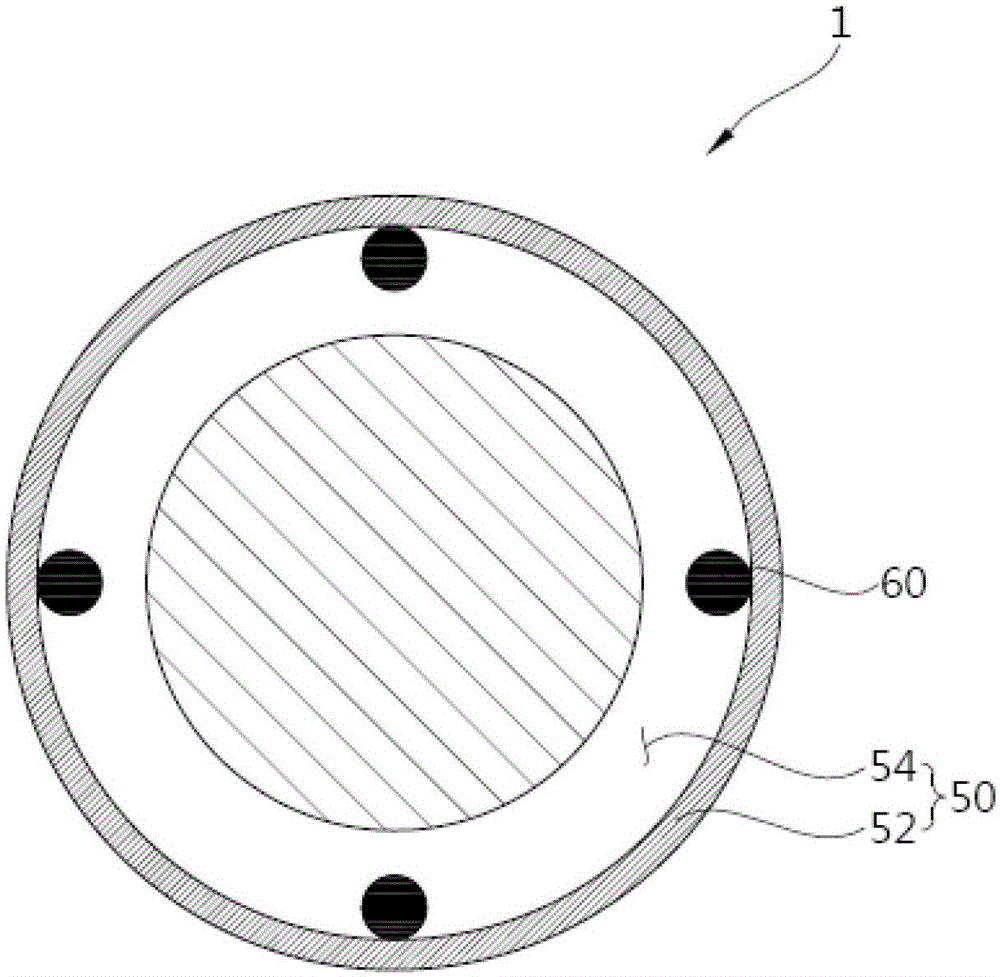

[0071] The reaction chamber 20 is used for accommodating the silicon core rod 30 and the jacket unit 50 . The number N of silicon core rods 30 is arranged inside the reaction chamber 20 and has a pair of silicon rods 32 that are energized by current. The polysilicon is deposited by the reaction of the process gas while being heated by the energized current. Moreover, the jacket unit 50 is formed with M receiving holes 54 for receiving N silicon core rods 30 having a pair of silicon rods 32, and the rea...

no. 2 example

[0094] Figure 5 is a perspective view of a polysilicon deposition apparatus according to a second embodiment of the present invention, Image 6 Yes Figure 5 A top view of the polysilicon deposition apparatus shown, and, Figure 7 It is a perspective view of a partial region of a jacket unit of a polysilicon deposition apparatus according to a second embodiment of the present invention combined with a shielding member.

[0095] Before explaining, it should be noted that Figure 7 The jacketed unit shown is shown in the Figure 5 and Figure 5 Partial area of the jacketed unit shown, and described below Figure 8 to Figure 10 Partial area of jacketed unit shown.

[0096] like Figure 5 to Figure 7 As shown, the polysilicon deposition apparatus 1 according to the second embodiment of the present invention includes a silicon core rod 130 , a jacket unit 150 and a shielding member 220 .

[0097] There are a plurality of silicon core rods 130 , and polysilicon is depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com