Culture method for increasing biomass and grease yield of microalgae

A cultivation method and biomass technology are applied in the cultivation field of improving the yield of microalgae biomass and oil, which can solve the problems of increasing the cost of high-concentration glucose, and achieve the effects of promoting the yield of biomass and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

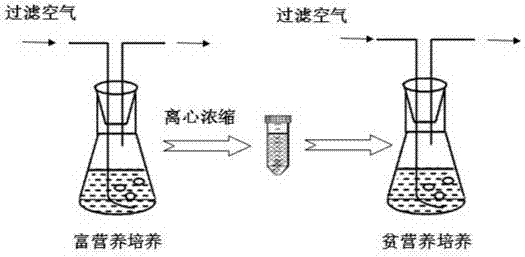

[0011] Example 1. The specific steps of the cultivation method for improving the yield of N.salina biomass and oil in this example are as follows (see the process flow chart figure 1 ):

[0012] 1. Eutrophic culture of microalgae: Inoculate Pseudochlorococcum N.salina into a normal nutrient-rich f / 2 medium, with an initial pH of 8, a temperature of 24±2°C, and an illumination of 79.29 μmol m -2 s -1 , Ventilation training to logarithmic growth phase. Nutrient-rich f / 2 medium, each liter contains: 33.6g artificial sea salt, 0.075g NaNO 3 , 0.00565g NaH 2 PO 4 ·2H 2 O, 1ml trace elements (T) and 1ml vitamins. Among them, each liter of trace element T contains: 4.16g Na 2 EDTA, 3.15g FeCl 3 ·6H 2 O, 0.18g MnCl 2 ·4H 2 O, 10mg CoCl 2 ·6H 2 O, 10mg CuSO 4 ·5H 2 O, 22mg ZnSO 4 ·7H 2 O, 6mg Na 2 MoO 4 ·2H 2 O. Each liter of vitamins contains: 100mg vitamin B1, 0.5mg vitamin B12 and 0.5mg vitamin H.

[0013] 2. Collection and concentration of microalgae: After the microchlorococcus N. sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com