Ground construction method for artificial icing climate laboratory

A construction method and laboratory technology, applied to floors, insulation layers, buildings, etc., can solve the problems of easy water ingress and moisture in the insulation layer, and achieve the effects of excellent bearing capacity, reduced fire risk, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

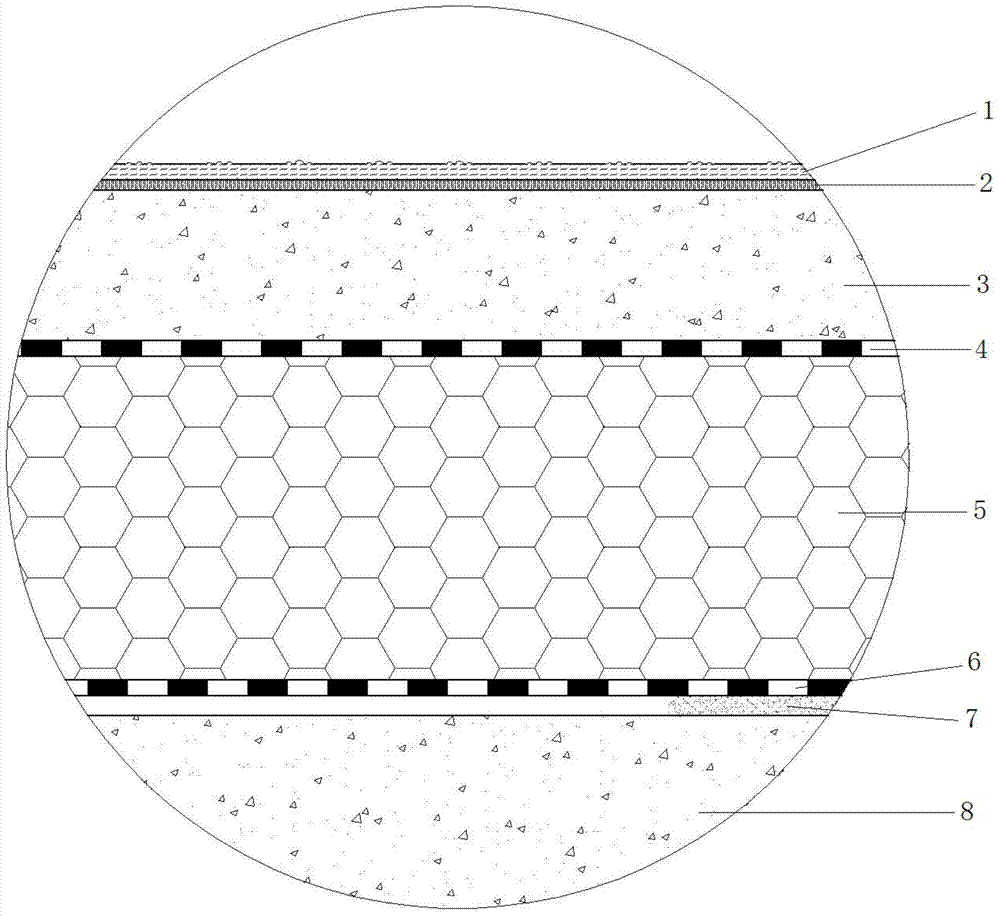

[0029] (1) Compact the plain soil layer on the ground surface of the artificial ice-covered climate laboratory to be constructed, bind two-way steel bars on the compacted plain soil layer, pour concrete slurry to form the first reinforced concrete layer 8, and maintain for 12 days;

[0030] (2), on the cured first reinforced concrete layer 8 formed in step (1), lay a layer of first waterproof membrane layer 7 with SBS modified asphalt waterproof membrane;

[0031] (3), apply a layer of cement mortar protective layer 6 on the first waterproof membrane layer 7 laid in step (2), with a thickness of 18mm, and maintain for 7 days;

[0032] (4), laying a layer of high-density polyurethane insulation board layer 5 on the cement mortar protective layer 6 applied in step (3);

[0033] (5), on the high-density polyurethane insulation board layer 5 laid in step (4), use SBS modified bitumen waterproof membrane to lay a second waterproof membrane layer 4;

[0034] (6), on the second wate...

Embodiment 2

[0039] (1) Compact the plain soil layer on the ground surface of the artificial ice-covered climate laboratory to be constructed, bind two-way steel bars on the compacted plain soil layer, pour concrete slurry to form the first reinforced concrete layer 8, and maintain for 18 days;

[0040] Step (2) is the same as embodiment 1;

[0041] (3), apply a layer of cement mortar protective layer 6 on the first waterproof membrane layer 7 laid in step (2), with a thickness of 22mm, and maintain for 10 days;

[0042] Steps (4) to (5) are the same as in Example 1;

[0043] (6), on the second waterproof membrane layer 4 laid in step (5), bind two-way steel bars, pour concrete slurry to form the second reinforced concrete layer 3, with a thickness of 120mm, and maintain for 18 days;

[0044] (7), on the cured second reinforced concrete layer 3 formed in step (6), paint a layer of epoxy resin wear-resistant floor paint layer 2, with a thickness of 2mm, and let it dry naturally for 4 days;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com