Self-propelled concrete spraying machine with spray head with functions of automatic rotation and traction

A concrete sprayer and automatic rotation technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of normal vehicle traffic, difficult implementation, and small culvert space, and achieve higher construction production efficiency and improved efficiency. Construction quality, the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

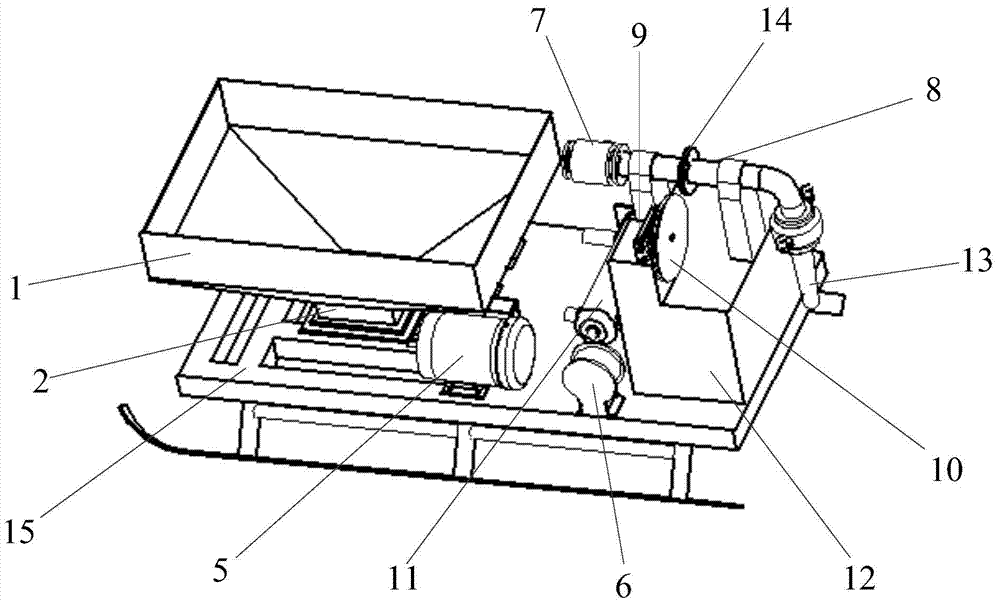

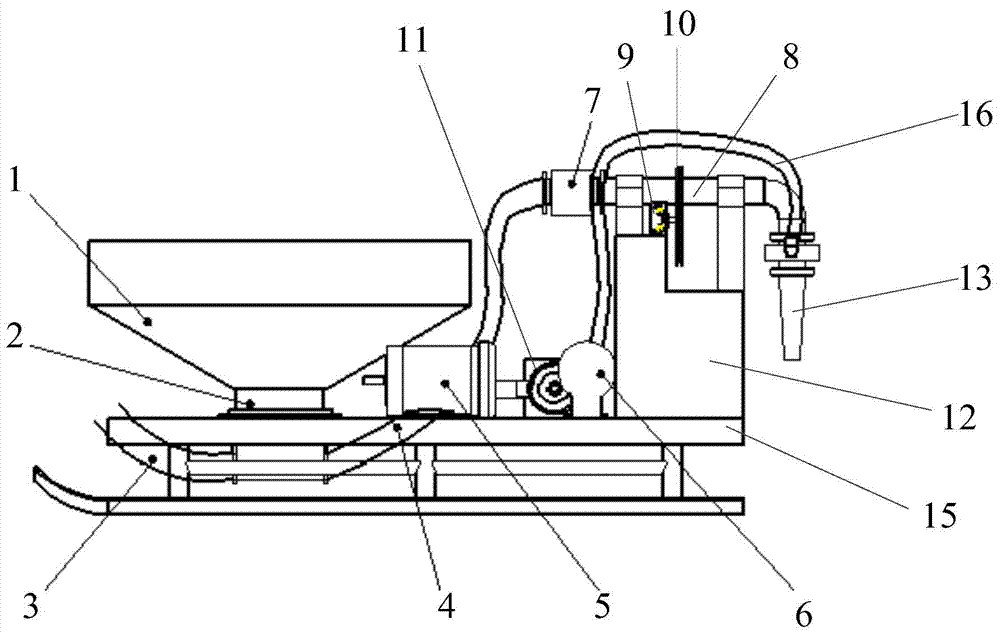

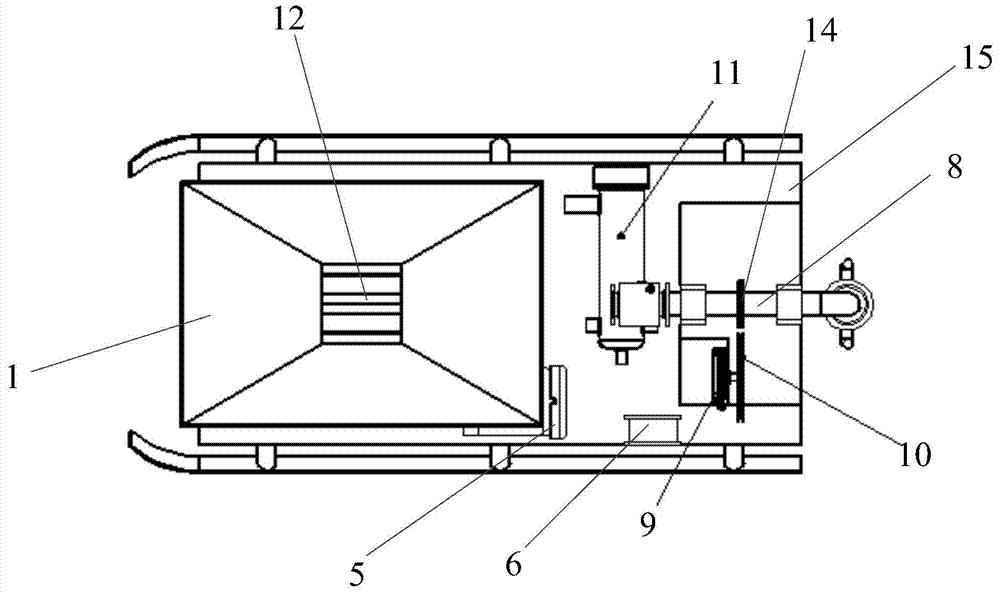

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] see Figure 1 to Figure 3 , the present invention comprises a sled with a sled 15, and a concrete feeding device with a paddle mixer 2 arranged on the sled 15, the paddle 2 is driven to rotate by a driving device, and the driving device is installed on the sled 15, the driving device is a motor 5 installed on the sled, and the output shaft of the motor 5 is fixed coaxially with the rotating shaft of the pusher; figure 2 As shown, the winch machine 11 is also installed on the sled board 15 to make the whole device move unidirectionally along the longitudinal direction; the rope at one end of the winch machine 11 is fixed on a firm object, and the whole device is controlled to move as a whole by controlling the winch machine to rotate. The concrete feeding device includes a conical hopper 1, and the dial mixer 2 is installed at the lower part of the conical hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com