Three-level multi-loop automatic combined type drier for high-humidity and high-viscosity material

A three-stage multi-loop, dryer technology, applied in dryers, non-progressive dryers, drying and other directions, can solve the problems of few tumble dryers, difficult to complete drying at one time, bending deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

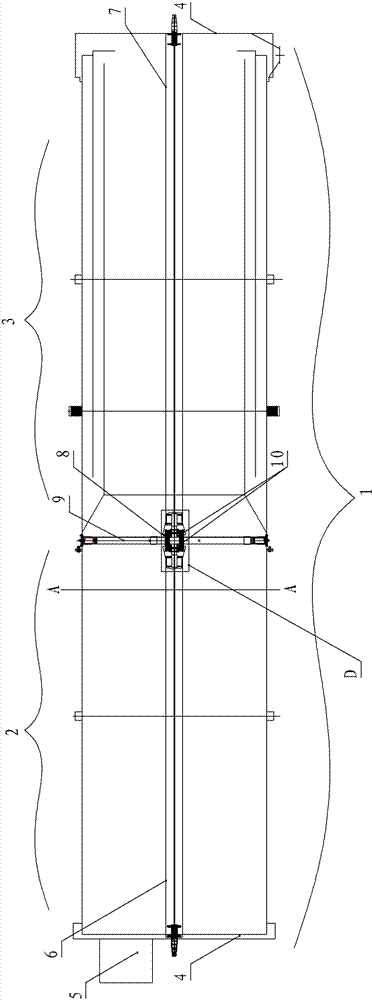

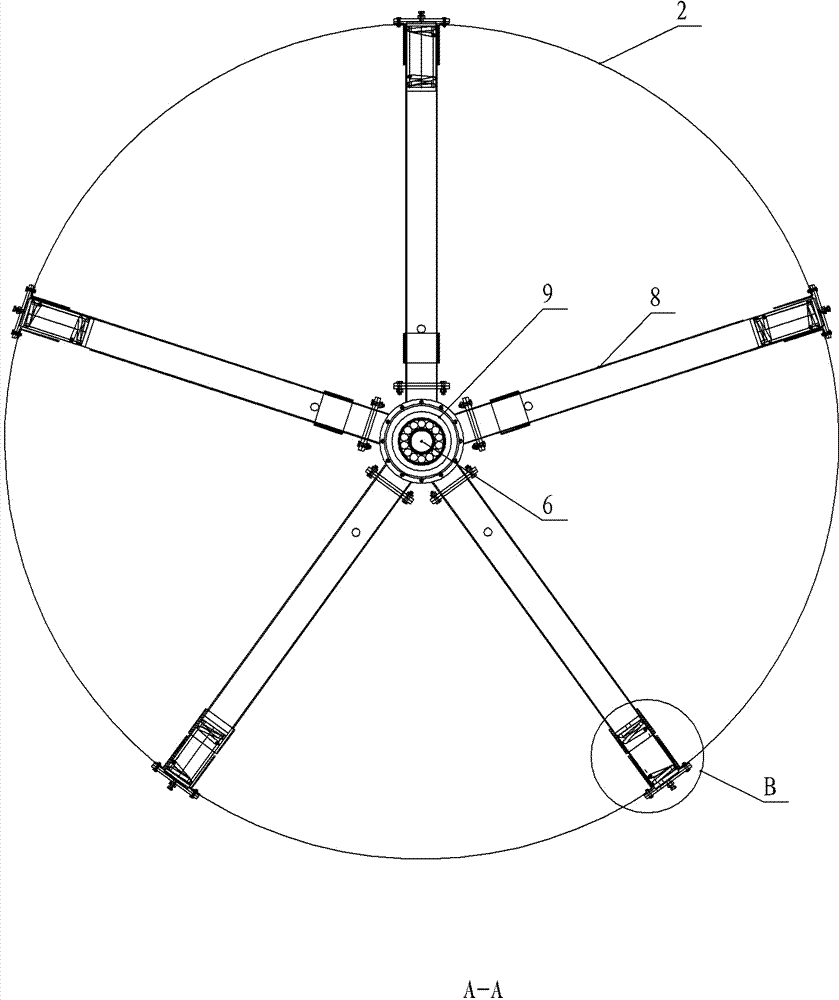

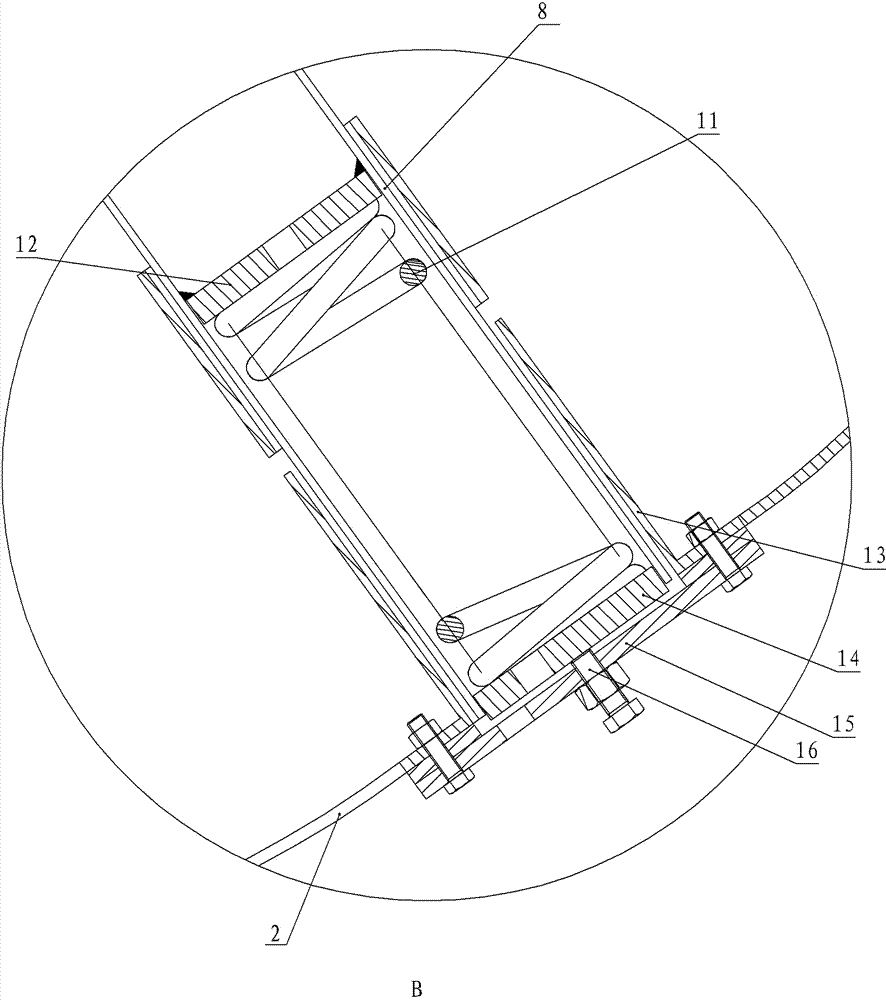

[0029] Embodiment one: see figure 1 , figure 2 , image 3 In the figure, a "rotary rake Feiteng" three-stage multi-circuit automatic combined high-humidity and high-viscosity material dryer includes at least the drum body, the covers at both ends of the drum body, the internal breaking shaft, and the heating air system. The drum body described above includes a single-layer drum section and a multi-layer drum section connected as one, the single-layer drum section has only one layer of drums, and there are at least two layers of drums in the multi-layer drum section, and the drums of the multi-layer drum section are from the inside To the outside, there are first-stage rollers, second-stage rollers...Nth-stage rollers. The rollers of the single-layer roller section are docked with the first-stage rollers of the multi-layer roller section. The broken shaft includes two sections, two sections The outer ends of the breaking shafts are respectively installed on the covers at bot...

Embodiment 2

[0034] Embodiment two: see Figure 4 , figure 2 , image 3 , Figure 5 In the figure, a "rotary rake Feiteng" three-stage multi-circuit automatic combined high-humidity and high-viscosity material dryer includes at least the drum body, the covers at both ends of the drum body, the internal breaking shaft, and the heating air system. The drum body described above includes a single-layer drum section and a multi-layer drum section connected as one, the single-layer drum section has only one layer of drums, and there are at least two layers of drums in the multi-layer drum section, and the drums of the multi-layer drum section are from the inside To the outside, there are first-stage rollers, second-stage rollers...Nth-stage rollers. The rollers of the single-layer roller section are docked with the first-stage rollers of the multi-layer roller section. The broken shaft includes two sections, two sections The outer ends of the breaking shafts are respectively installed on the...

Embodiment 3

[0041] Embodiment three: see figure 1 , figure 2 , image 3 , Image 6 , Figure 7 , a "rotary rake Feiteng" three-stage multi-circuit automatic combined high-humidity and high-viscosity material dryer, at least including a drum body, covers at both ends of the drum body, an internal dispersing shaft, and a heating air system. The drum body includes a single-layer drum section and a multi-layer drum section connected as one. The single-layer drum section has only one layer of drums, and there are at least two layers of drums in the multi-layer drum section. The drums of the multi-layer drum section are from inside to outside The first-stage roller, the second-stage roller...the N-stage roller in turn, the roller of the single-layer roller section is docked with the first-stage roller of the multi-layer roller section, and the breaking shaft includes two sections, and the two-stage breaking The outer ends of the shaft are respectively installed on the covers at both ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com