Method for positioning and homogenizing residual stress of thermal shock compounding

A residual stress and thermal vibration technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of small processing deformation, lack of implementation applications, limited effect of vibration aging technology, etc., to increase molecular vitality, The effect of simulation and experiment is consistent, saving the time of testing and comparison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

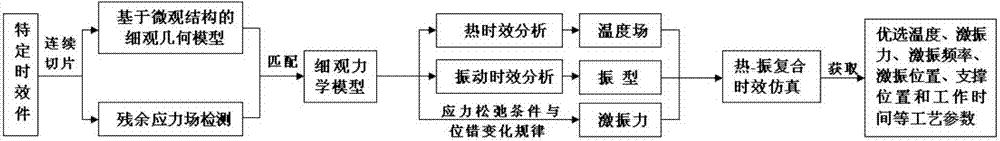

[0042] Combined with the accompanying drawings figure 2 Describe the specific steps of the thermal shock composite residual stress localization and homogenization method described in the present invention:

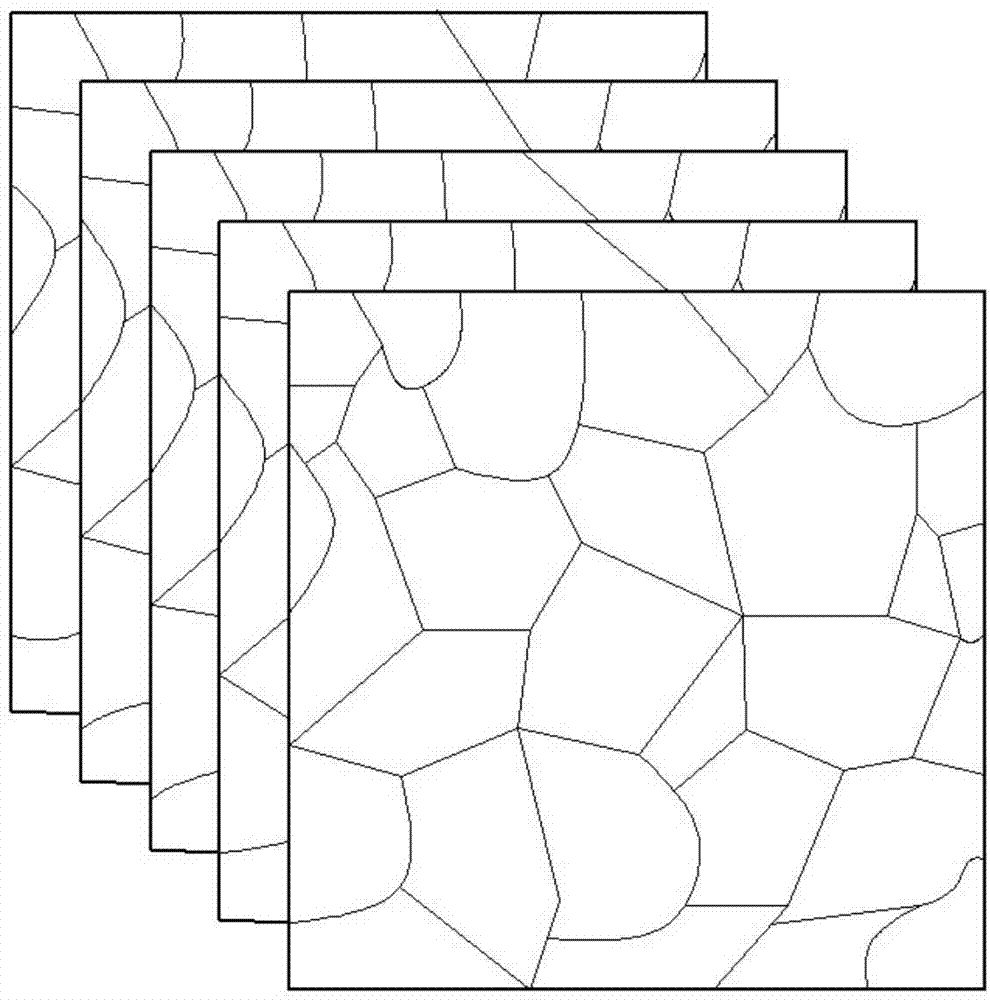

[0043] Step 1: Carry out continuous slicing for a specific workpiece or its blank, such as figure 1 As shown, after preparing the sample, the digital image of each section of the material is obtained by means of a transmission electron microscope, which is converted into a three-dimensional model by segmentation processing, and then the geometric model is established in the finite element software to obtain a mesoscopic geometric model based on the microstructure;

[0044] Step 2: While continuously slicing in step 1, detect the residual stress of each layer through X-ray diffraction equipment, and obtain the three-dimensional residual stress field of the workpiece;

[0045] Step 3: Mesh the geometric model of step 1, then match it with the residual stress field measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com