Manufacturing process of cross-linked polyethylene insulated cable main terminal molding stress control module

A cross-linked polyethylene, stress control technology, used in cable accessories, cable installation, cable installation devices, etc., can solve the problems of local electric field distortion, insulation breakdown, restricting the safe operation of cable systems, etc., to achieve stable electrical performance, The effect of the production process is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

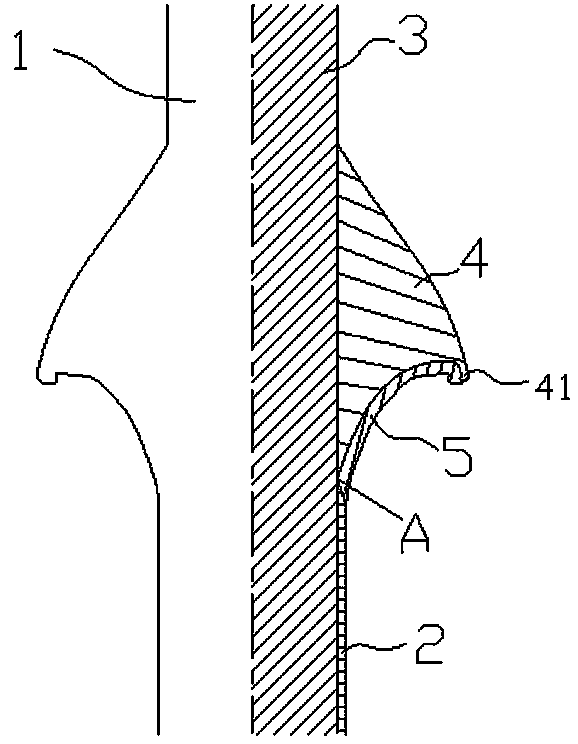

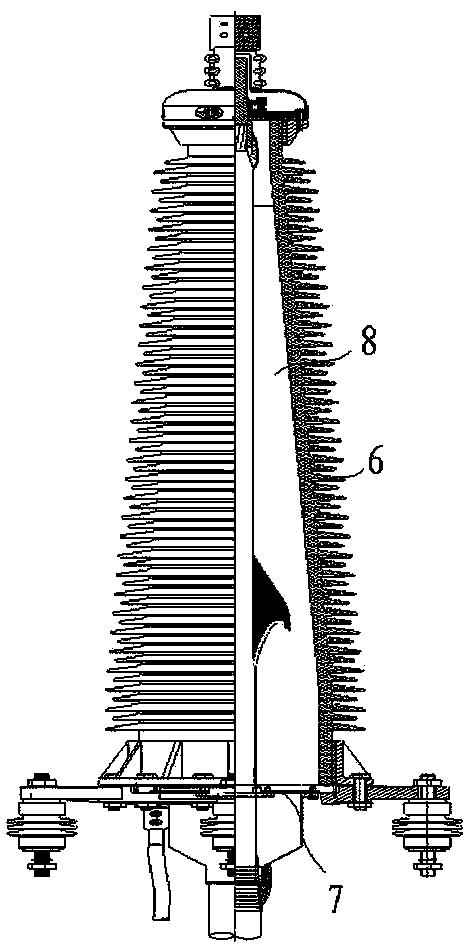

[0013] The manufacturing process of the present invention is used to overcome the problem of electric field distortion at the stripping and cutting part of the semiconductive layer of the cable main body terminal, and prevent this part from being broken down; this part mainly performs several aspects of work: the melting and crosslinking process of the factory insulating layer and the filling insulation; Melt crosslinking process of factory semiconducting layer and filled semiconducting layer; melt crosslinking process of filled insulating and filled semiconducting layer. After the above work is completed, the injection molding process of the stress control module can be completed. After the above process is completed, the production of the cable terminal head is further carried out.

[0014] Specifically, such as figure 1 As shown, according to the requirements of the production process, the outer sheath and metal sheath at the cable terminal are stripped and cut, the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com