Thin type flat linear vibration motor

A linear vibration and flat technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of poor universality, inconvenient replacement, and low service life of coils, and achieve the effects of improving service life, avoiding impact, and protecting coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

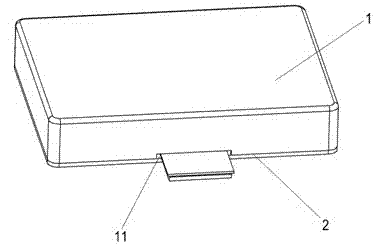

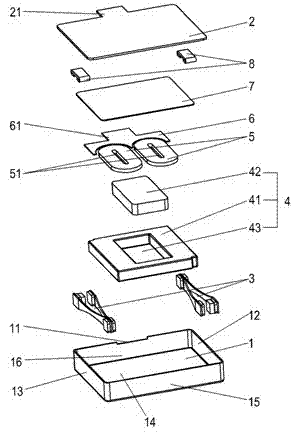

[0052] such as 1 and figure 2 As shown, this embodiment provides a vibration motor, including a casing 1 and a cover plate 2 mounted on the casing 1, the casing 1 has a bottom surface 14, and a first side wall 12 connected to the bottom surface 14 , the second side wall 13, the front wall 16 and the rear wall 15, the bottom surface 14 and the above-mentioned side wall of the casing 1 enclose a cavity with a specific height, and the front wall 16 is provided with a concave installation groove 11 , the cover plate 2 has an outwardly protruding cover plate protrusion 21, and the cover plate protrusion 21 is inserted into the concave installation groove 11, so as to connect the cover plate 2 and the casing 1 Composed together to form an installation space.

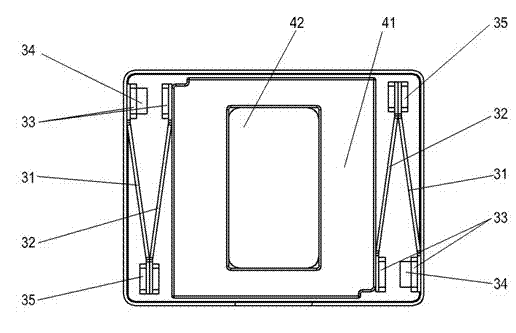

[0053] In the installation space, a vibrating assembly 4 and two coils 5 connected in series are installed sequentially from the bottom surface 14 of the casing 1 towards the direction of the cover plate 2 (the coil 5 is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com