Laser processing device and laser processing method

A technology of laser processing and processed objects, applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve the problems of difficult precision processing, impossible precision processing, etc., and achieve the effect of high plane precision and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

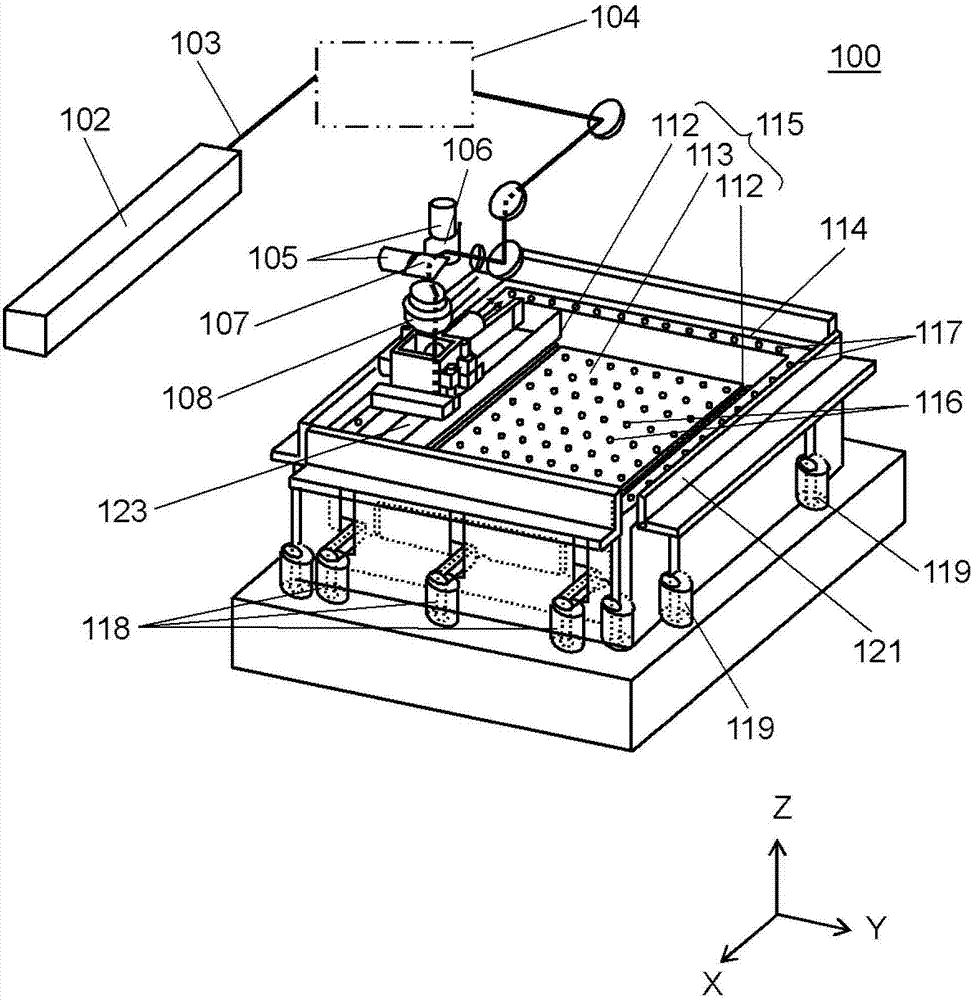

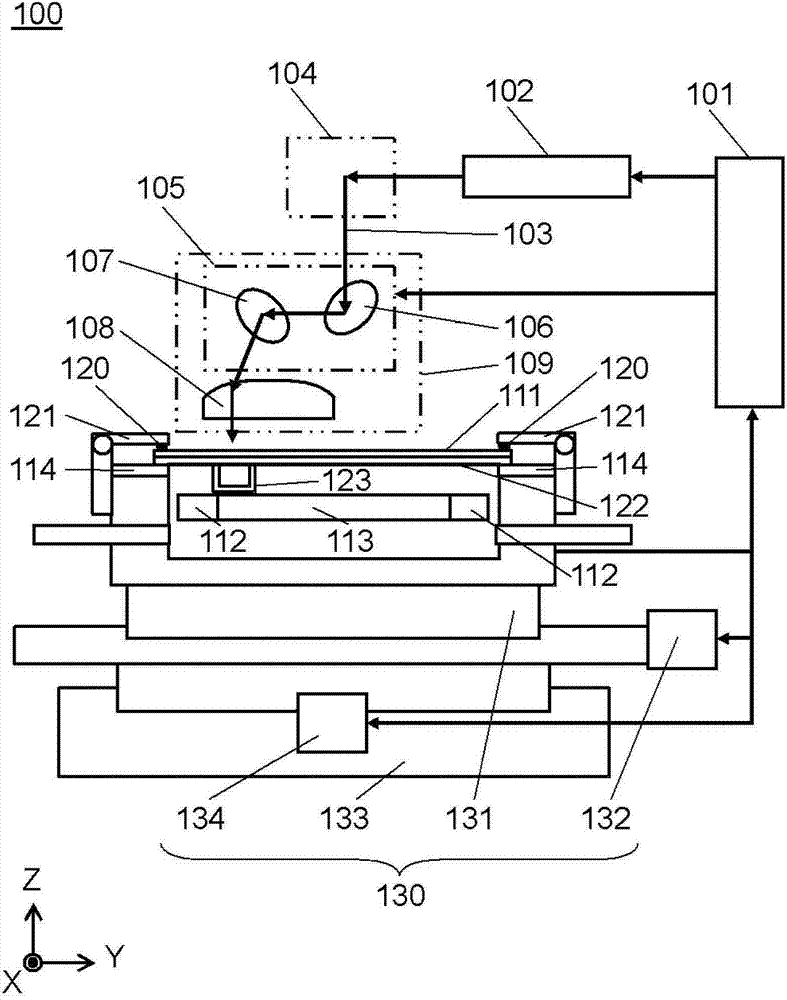

[0057] figure 1 It is a perspective view which shows the schematic structure of the laser processing apparatus 100 which concerns on an example of embodiment of this invention. exist figure 1 In , in order to facilitate visual confirmation of the structure of the device, the workpiece and the jig sheet described later are removed. In addition, in order to explain the detailed structure, figure 2 It is a cross-sectional view of the laser processing apparatus 100 viewed from the X direction.

[0058] exist figure 1 and figure 2 In this case, a laser beam 103 is emitted from a laser oscillator 102 and guided to an optical system 104 including mirrors and lenses. The optical system 104 adjusts the density (laser diameter) of the laser beam 103 , shapes the shape, suppresses stray light, and the like so that the laser beam 103 is directed in a predetermined direction.

[0059] The laser beam 103 after passing through the optical system 104 is directed to a galvano scanne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com