Thick broad-bean sauce and energy-saving making method thereof

A technology of bean paste and mildew, which is applied in food preparation, food science, application, etc., can solve the problems of hindering the economic benefits of enterprises, occupying the fermentation tank of soy sauce grains, and unfavorable technological innovation, so as to reduce the investment in fixed assets and reduce the operation of enterprises cost, and the effect of reducing facility occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Pour 75kg of dry white petals into the soaking pot from the feeding hole, and start the rotating soaking pot, add 60kg of water heated to boiling into the rotating pot for mixing, add water while rotating, and continue rotating and soaking after the water is added After 10 minutes, quickly inject cold water to cool down to 40°C, drain the water and "sweat away", open the lid in time, add 225g of 3811 Aspergillus oryzae seed koji, seal the cover, start the rotation of the foam tank, fully mix the seed koji and wet petals, and open Cover and put the material into the koji room through the conveyor belt; control the temperature of the product at 32°C, enter the koji for about 20 hours, and perform the first turn over, about 10 hours after the first turn, perform the second turn over, After turning the koji for the second time, control the temperature of the product at 28°C, keep the temperature of the product for 40 hours and then release the koji, and wash the molded petals...

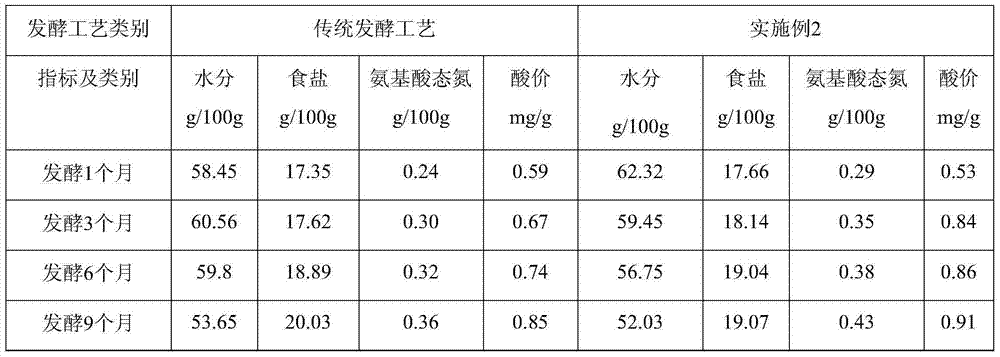

Embodiment 2

[0047] Pour 80kg of dry white petals into the foam tank from the feeding hole, start the rotary foam tank, add 60-65kg of water heated to boiling into the rotary pot for mixing, add water while rotating, and continue to Rotate and soak for 15 minutes, quickly inject cold water to cool down to 40°C, drain the water and "sweat away", open the lid in time and add 320g of Aspergillus oryzae seed koji, then seal the cover, start the foam tank to rotate, fully mix the seed koji and wet petals, Open the cover and discharge the material and send the koji material into the koji making room through the conveyor belt; control the temperature of the product at 34°C, enter the koji for 20 hours, and perform the first turning over, 10 hours after the first turning, perform the second turning over, and the second turning over After turning the koji twice, set the temperature of the control product to 30°C, keep the temperature of the product for 40 hours and then release the koji, and wash th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com