Three-shaft full-automatic edge rolling machine

A rounder, fully automatic technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of difficulty in meeting workpieces of different diameters, complex structure of the rounder, and limited use range, etc. Wide, simple structure, convenient replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

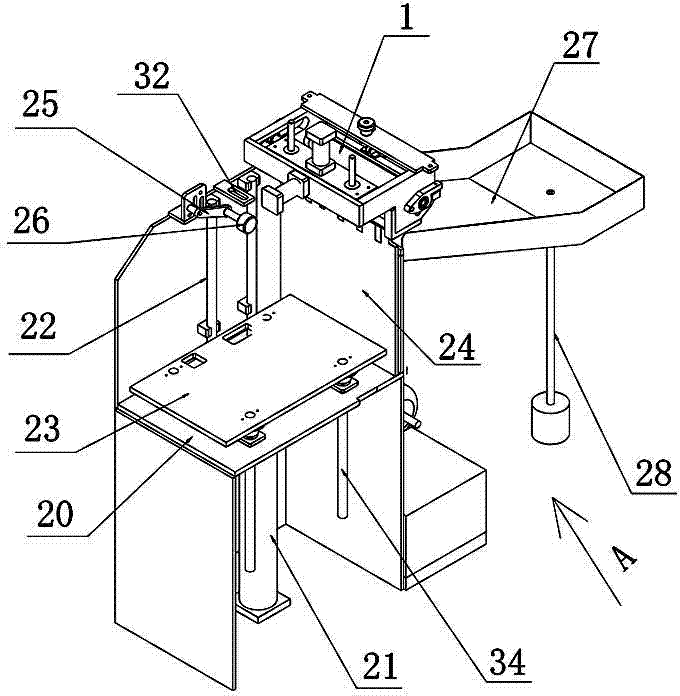

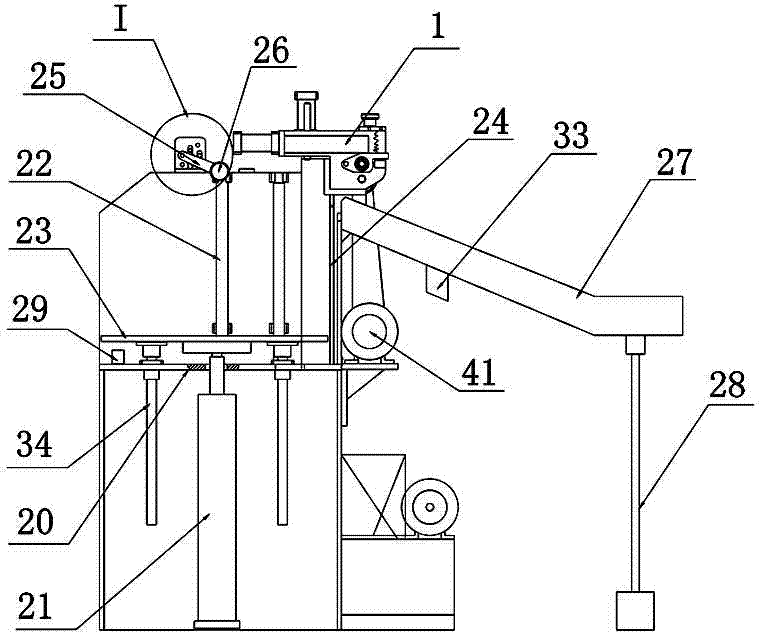

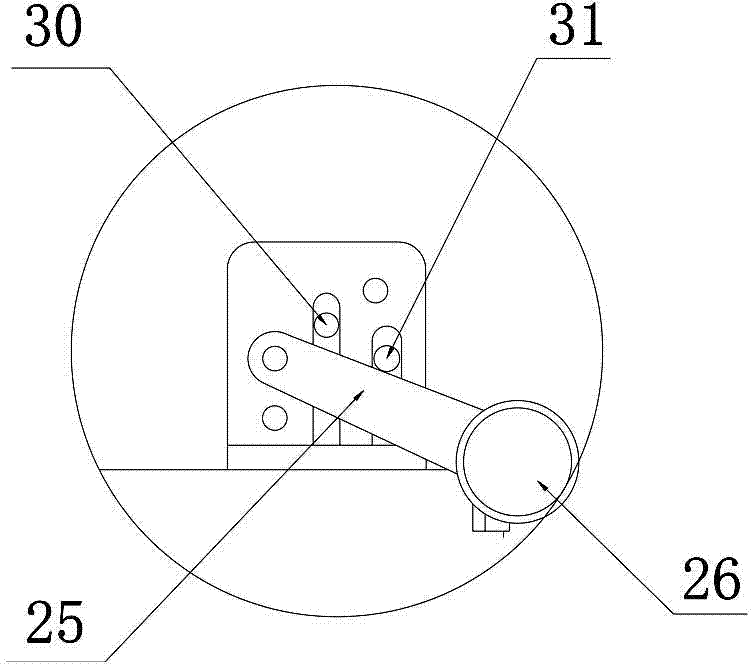

[0019] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the three-axis automatic rolling machine of the present invention includes a fuselage, a head 1 and a power drive system and a control system, and the fuselage is located in the The feed port and discharge port of the head 1 are respectively provided with a discharge mechanism and a discharge mechanism. The head 1 includes a feed mechanism and a roll forming mechanism arranged on the frame 2. The junction of the circular forming mechanism is provided with a guide plate 3, and the feeding mechanism includes a suction device that is driven up and down by a suction cylinder 4 vertically arranged on the frame 2, and a driving device is provided at the front of the suction device. The pusher cylinder 5 of its horizontal movement, the cylinder barrel end of described suction cylinder 4 is fixed on the slide plate 35 that moves horizontally along frame 2, and described slide plate 35 is fixedly connected with the piston rod end of pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com