Welding robot based on rectangular coordinate system

A technology of welding robot and Cartesian coordinate system, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high manufacturing cost, poor versatility, and complex structure, so as to reduce construction cost, facilitate placement, beautiful layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following describes the present invention in detail with reference to the drawings and embodiments:

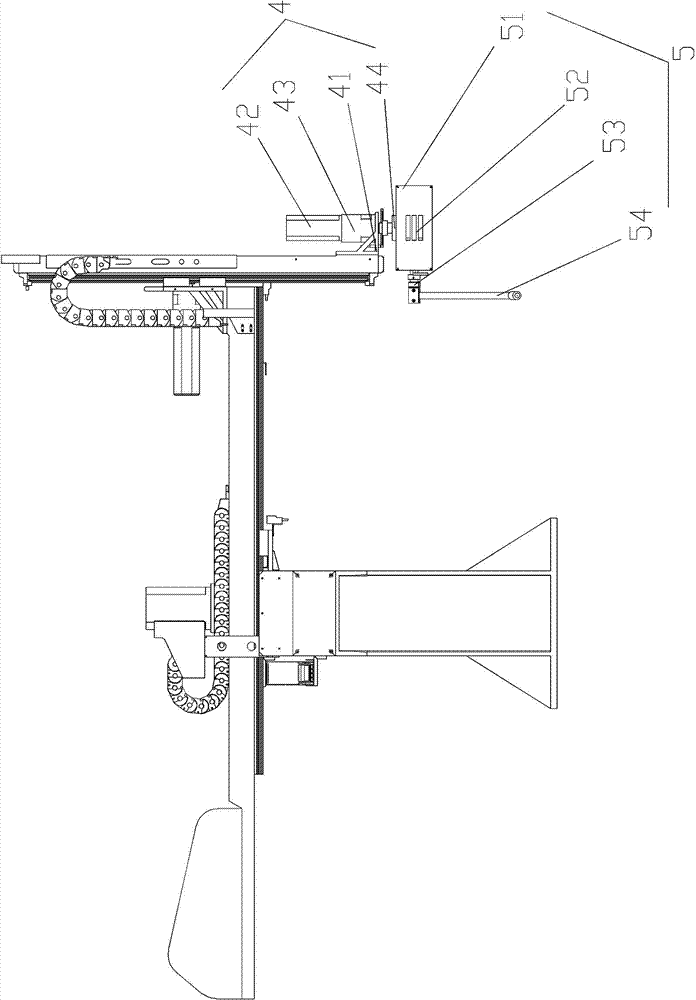

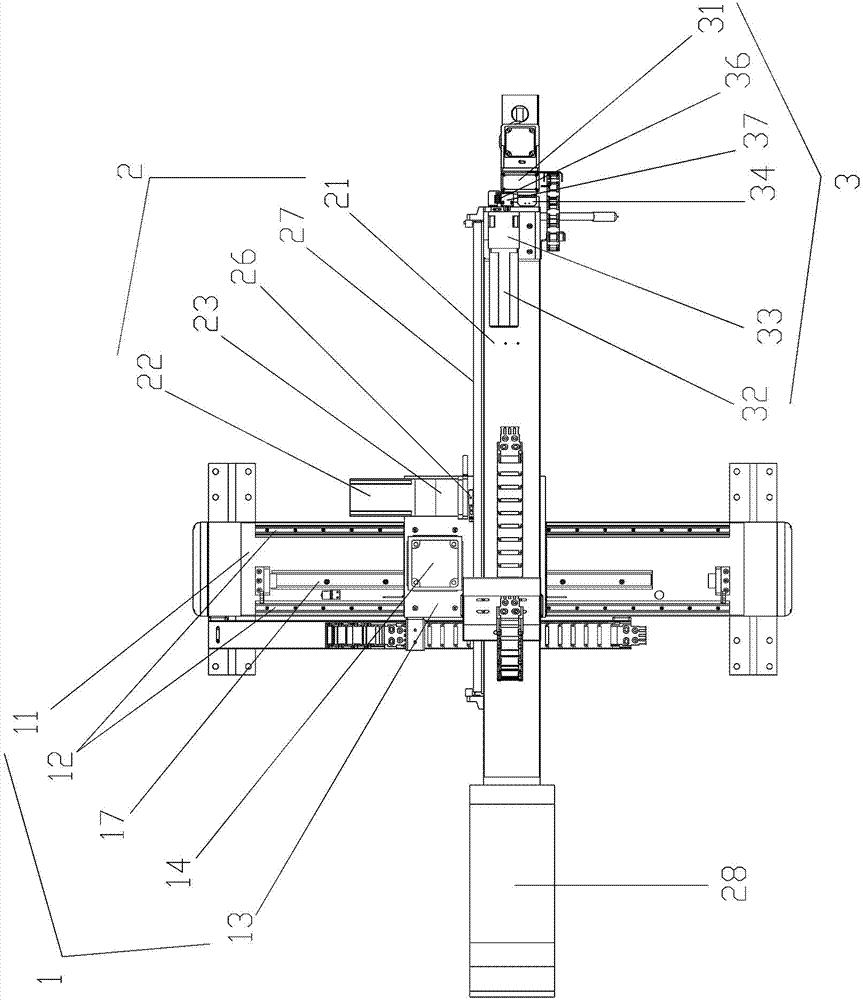

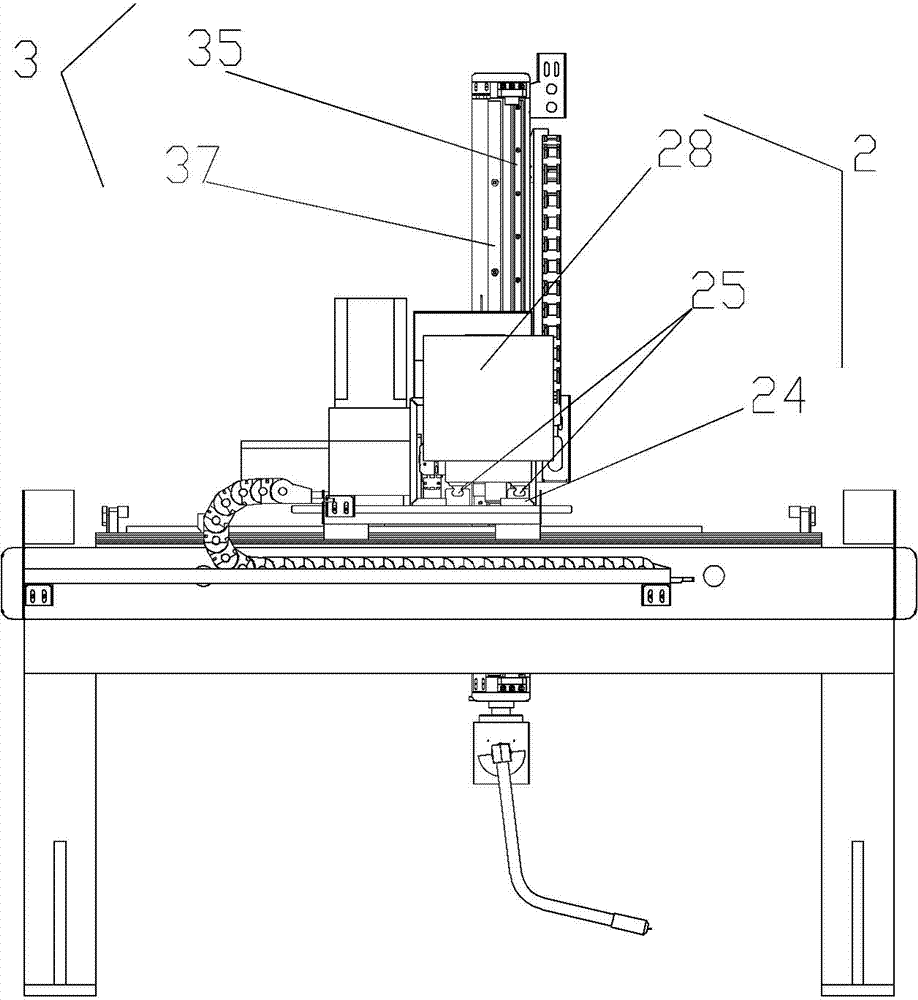

[0035] Such as Figure 1-Figure 4 The illustrated embodiment of the present invention is a welding robot based on a Cartesian coordinate system. The robot includes: an X-axis base mechanism 1 includes: a base 11; two first guide rails 12: mounted on the base 11; X Shaft sliding table 13: installed on the first guide rail 12; first motor 14: installed on the X-axis sliding table 13, the first motor is controlled by the control system; the first planetary gear reducer 15: cooperates with the first motor 14 Installed on the X-axis sliding table, the output shaft extends downwards outside the X-axis sliding table; the first gear 16: arranged under the X-axis sliding table and fixedly connected to the first planetary gear reducer 15; the first rack 17 : Installed on the base 11, meshed with the first gear 16 and driven by it; among them, the first motor 14 drives the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com