Method and device for preparing biaxially oriented polystyrene (Bops) sheet material

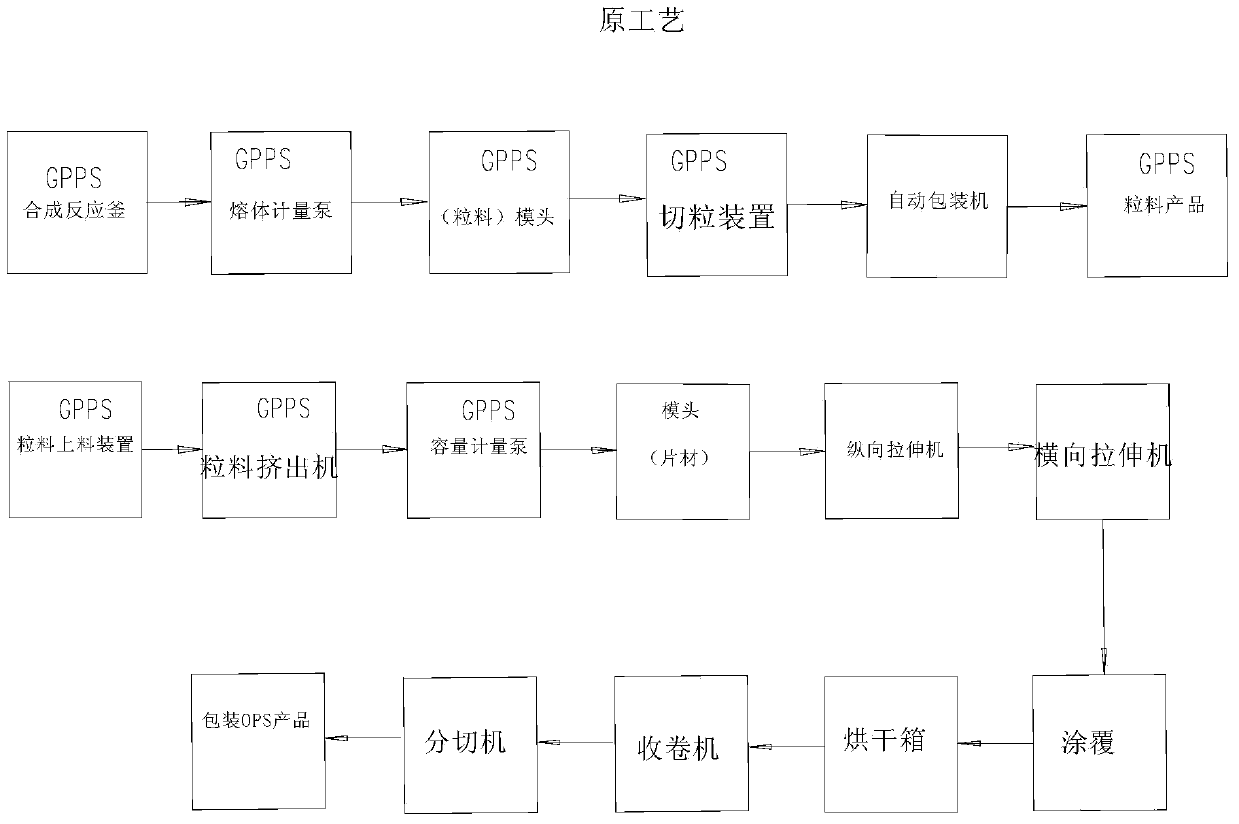

A polystyrene sheet, biaxially stretched technology, applied in the field of preparation of biaxially stretched polystyrene sheets, can solve the problems of many equipment, long process, complicated process, etc., and achieve simple process, short process, and packaging saving Effects of fees and shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

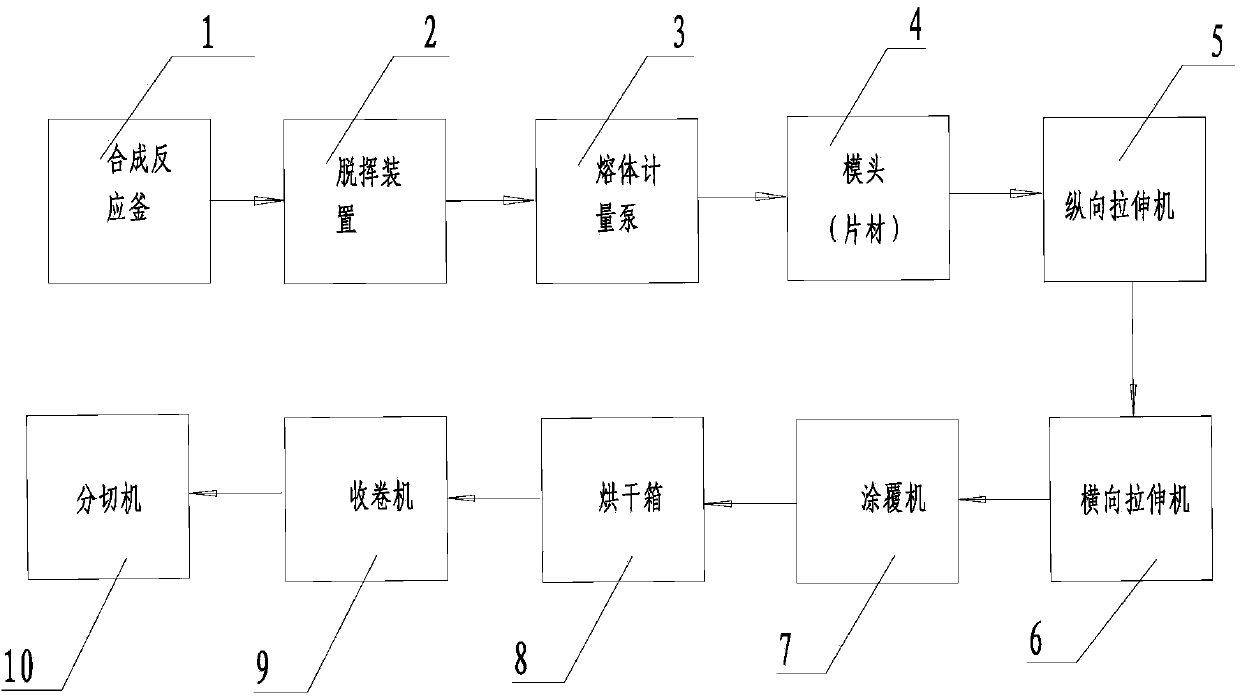

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: a kind of preparation method of biaxially stretched polystyrene sheet, it comprises the following steps:

[0020] (1) Synthesis of polystyrene resin; synthesis reaction kettle, temperature: 160°C, vacuum degree: 0.01-0.1Mpa; (2) Devolatilization device: temperature: 240°C, vacuum degree: 0.01-0.1Mpa; (3) melting Volume metering gear pump, temperature 230°C, pressure 3Mpa; (4) cast sheet; sheet die, temperature 230°C, pressure: 3Mp; (5) longitudinal stretching: temperature 145°C, multiple: 3.5 times; (6) Transverse stretching: temperature is 145°C, stretching ratio: 3.5 times.

[0021] The following steps are also included: (7) coating: (8) drying: the temperature is 90-120°C; (9) winding: (10) cutting: according to the standard.

Embodiment 2

[0022] Embodiment 2: a kind of preparation method of biaxially stretched polystyrene sheet comprises the following steps:

[0023] (1) Synthesis of polystyrene resin; synthetic reaction kettle, temperature: 140°C, vacuum degree: 0.01-0.1Mpa; (2) devolatilization device: temperature 220°C, vacuum degree: 0.01-0.1Mpa; (3) melting Volume metering gear pump, temperature: 190°C, pressure: 23Mpa; (4) cast sheet; sheet die, temperature: 230°C; pressure: 23Mpa; (5) longitudinal stretching: temperature: 110°C, stretching ratio: 1.5 times; (6) Transverse stretching: temperature is 110°C, stretching ratio: 1.5 times.

[0024] The following steps are also included: (7) coating: (8) drying: the temperature is 90-120°C; (9) winding: (10) cutting: according to the standard.

Embodiment 3

[0025] Example 3: (1) polystyrene resin synthesis; synthetic reaction kettle, temperature: 160°C, vacuum: 0.01-0.1Mpa; (2) devolatilization: temperature: 220°C, vacuum: 0.01-0.1Mpa; ( 3) Melt delivery metering pump, temperature 210°C, pressure 15Mpa (4) cast sheet; sheet die, temperature 130°C; pressure: 12Mpa; (5) Longitudinal stretching: temperature 120°C, stretch Multiplier: 3 times; (6) Transverse stretching: temperature is 120°C, stretching ratio: 2.5 times.

[0026] The following steps are also included: (7) coating: (8) drying: the temperature is 90-120°C; (9) winding: (10) cutting: according to the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com