Waterborne epoxy zinc-rich coating modified by nano conductive carbon material and preparation method thereof

A water-based epoxy zinc-rich, nano-conductive technology, used in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of increasing the cost of steel structure painting and maintenance, short effective anti-corrosion time, etc., to improve anti-corrosion performance, Improve flexibility and enhance the effect of current conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

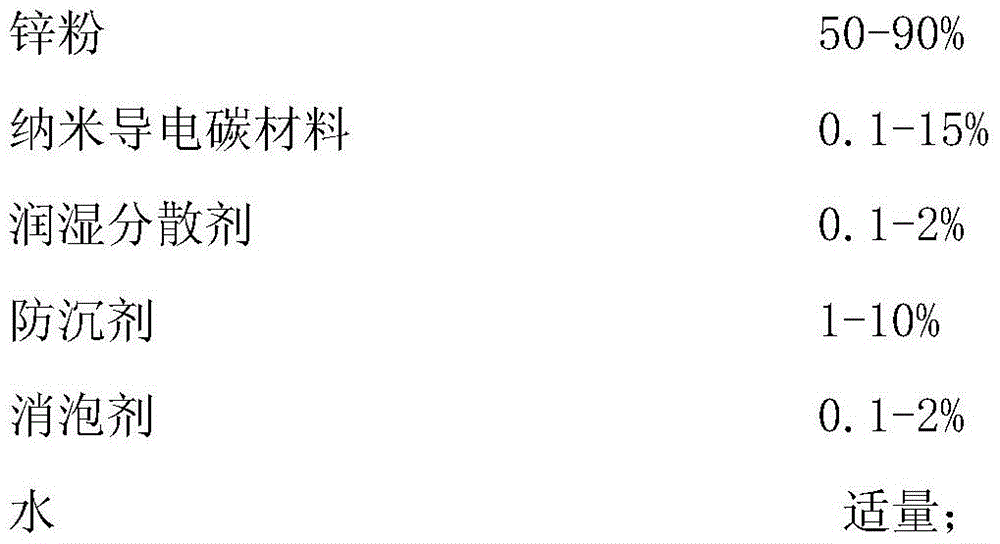

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.35 g of hydroxyl multi-walled carbon nanotubes and ultrasonically disperse them in 10 ml of deionized water to prepare multi-walled carbon nanotubes slurry;

[0028] (2) Add 100g of epoxy emulsion, 1g of FX600, 1g of AP7015 and 50ml of deionized water into the mixing tank of the high-speed disperser, stir at 200r / min for 20 minutes, and disperse evenly;

[0029] (3) Add 156g of zinc powder and 7.5g of sodium montmorillonite successively while continuing to stir, and stir at 600r / min;

[0030] (4) Add the multi-walled carbon nanotube slurry prepared in (1) gradually to the slurry obtained in (3), and disperse at a high speed of 1500r / min for 30 minutes to prepare component A;

[0031] (5) Add 40g of amine-modified curing agent emulsion (component B) with a solid content of 50% to component A, stir gently, and sieve to obtain nano-conductive carbon material modified water-based zinc-rich epoxy coating;

[0032] (6) Spray the prepared nano-conductive carbon m...

Embodiment 2

[0034] (1) Weigh 0.56 hydroxyl multi-walled carbon nanotubes and ultrasonically disperse them in 10ml deionized water to prepare multi-walled carbon nanotubes slurry;

[0035] (2) Add 100g of epoxy emulsion, 1g of FX600, 1g of AP7015 and 50ml of deionized water into the mixing tank of the high-speed disperser, stir at 200r / min for 20 minutes, and disperse evenly;

[0036] (3) Add 156g of zinc powder and 7.5g of sodium montmorillonite successively while continuing to stir, and stir at 600r / min;

[0037] (4) Add the multi-walled carbon nanotube slurry prepared in (1) gradually to the slurry obtained in (3), and disperse at a high speed of 1500r / min for 30 minutes to prepare component A;

[0038] (5) Add 40g of amine-modified curing agent emulsion (component B) with a solid content of 50% to component A, stir gently, and sieve to obtain nano-conductive carbon material modified water-based zinc-rich epoxy coating;

[0039] (6) Spray the prepared nano-conductive carbon material m...

Embodiment 3

[0041] (1) Weigh 0.98 g of hydroxyl multi-walled carbon nanotubes and ultrasonically disperse them in 20 ml of deionized water to prepare multi-walled carbon nanotubes slurry;

[0042] (2) Add 100g of epoxy emulsion, 1g of FX600, 1g of AP7015 and 50ml of deionized water into the mixing tank of the high-speed disperser, stir at 200r / min for 20 minutes, and disperse evenly;

[0043] (3) Add 156g of zinc powder and 7.5g of sodium montmorillonite successively while continuing to stir, and stir at 600r / min;

[0044] (4) Add the multi-walled carbon nanotube slurry prepared in (1) gradually to the slurry obtained in (3), and disperse at a high speed of 1500r / min for 45 minutes to prepare component A;

[0045] (5) Add 40g of amine-modified curing agent emulsion (component B) with a solid content of 50% to component A, stir gently, and sieve to obtain nano-conductive carbon material modified water-based zinc-rich epoxy coating;

[0046] (6) Spray the prepared nano-conductive carbon m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com