Adhesive production process method

A production process and adhesive technology, applied in the direction of adhesives, adhesive additives, epoxy resin glue, etc., can solve the problems of low production efficiency, time-consuming production efficiency, long production time, etc., and achieve complete defoaming and good dispersion effect, the effect of increasing the dispersion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

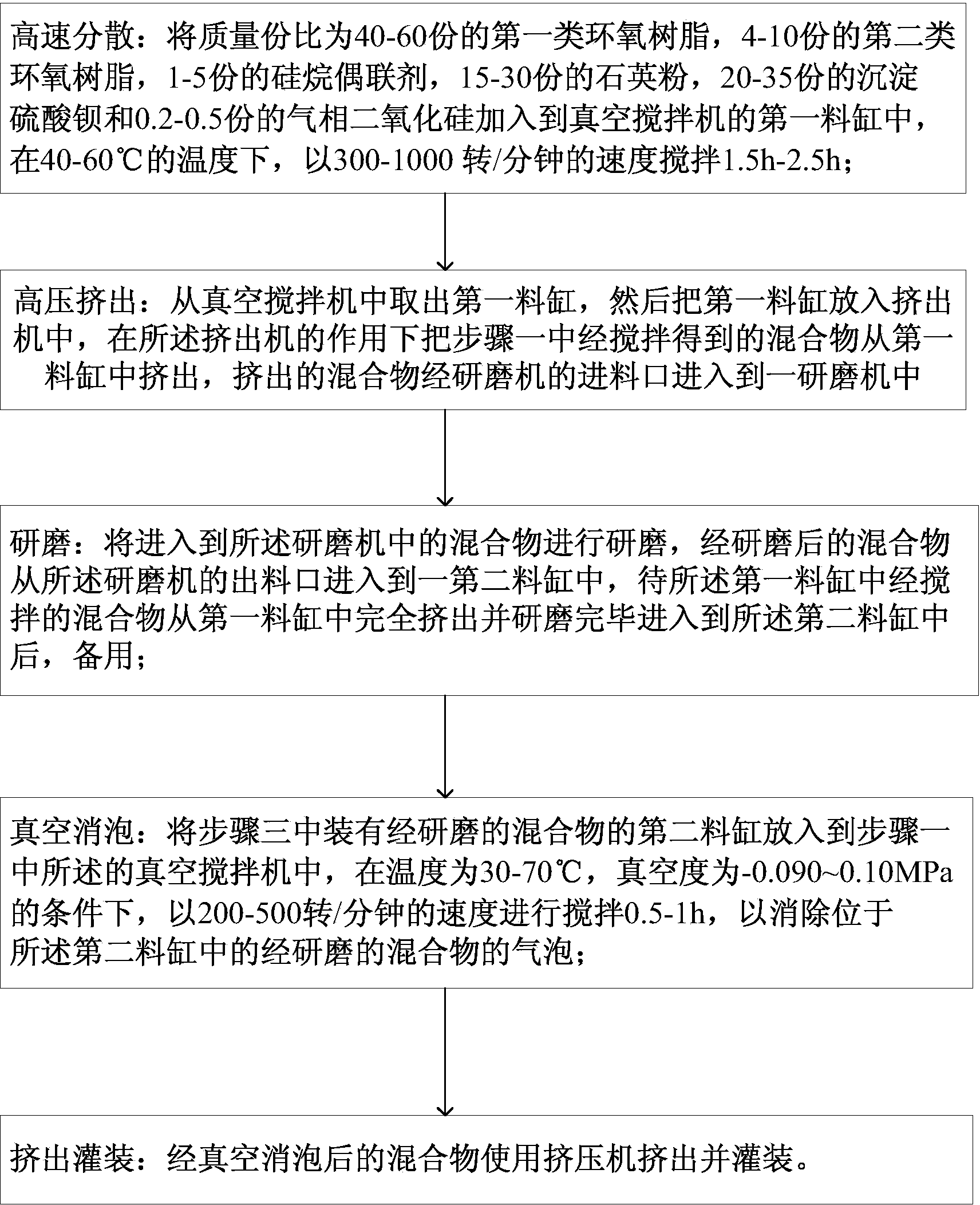

Method used

Image

Examples

Embodiment 1

[0024] Step 1, high-speed dispersion: first add epoxy resin E42 with a mass part ratio of 40 parts into the first material tank of the high-viscosity vacuum mixer. The high-viscosity vacuum mixer is equipped with a heating jacket, and the stirring motor is started. At a temperature of 40°C, stir at a speed of 300 rpm. While stirring, start the scraping motor to start the scraping parts, and then add epoxy resin CY with a mass ratio of 4 parts in sequence while stirring. -183, 1 part of silane coupling agent, 15 parts of quartz powder, 20 parts of precipitated barium sulfate and 0.2 part of fumed silica, after adding all the materials, stir for 0.5h.

[0025] Step 2, high-pressure extrusion: Take out the first material cylinder from the vacuum mixer described in step 1, then put the first material cylinder into a high-viscosity hydraulic extruder, and under the condition of a pressure of 12MPa, the hydraulic cylinder The piston rod is moved downward under the action, and the mi...

Embodiment 2

[0030] Step 1, high-speed dispersion: first add the mixture of epoxy resin E44 and epoxy resin E51 with a mass part ratio of 60 parts into the first material tank of the high-viscosity vacuum mixer. The high-viscosity vacuum mixer has a heating clamp set, start the stirring motor to stir, and stir at a temperature of 60°C at a speed of 1000 rpm. While stirring, start the scraping motor to start the scraping parts, and then add mass parts in sequence while stirring. The ratio is 10 parts of epoxy resin CY-184, 5 parts of silane coupling agent, 30 parts of quartz powder, 35 parts of precipitated barium sulfate and 0.5 part of fumed silica. After all materials are added, stir for 0.5 h.

[0031] Step 2, high-pressure extrusion: Take out the first material cylinder from the vacuum mixer described in step 1, then put the first material cylinder into a high-viscosity hydraulic extruder, and under the condition of a pressure of 16MPa, in the hydraulic cylinder The piston rod is move...

Embodiment 3

[0036] Step 1, high-speed dispersion: first add the mixture of epoxy resin E42 and epoxy resin E51 with a mass part ratio of 50 parts into the first material tank of the high-viscosity vacuum mixer. The high-viscosity vacuum mixer has a heating clamp set, start the stirring motor to stir, and stir at a temperature of 50°C at a speed of 700 rpm. While stirring, start the scraping motor to start the scraping parts, and then add mass parts in sequence while stirring. The ratio is 7 parts of epoxy resin CY-184 and epoxy resin CY-183 mixture, 3 parts of silane coupling agent, 22 parts of quartz powder, 27 parts of precipitated barium sulfate and 0.4 parts of fumed silica, After all the materials were added, it was stirred for another 0.5h.

[0037] Step 2, high-pressure extrusion: Take out the first material cylinder from the vacuum mixer described in step 1, then put the first material cylinder into a high-viscosity hydraulic extruder, and under the condition of a pressure of 14MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com