Pulping low-concentration slag removal system

A pulping and pulping technology, which is applied in textiles, papermaking, fiber raw material processing, etc., can solve the problems of increasing pipeline wear, increasing maintenance costs and maintenance difficulties, increasing pipeline length, etc., and achieves the effect of reducing pipeline wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

[0017] The following examples are non-limiting examples of the invention.

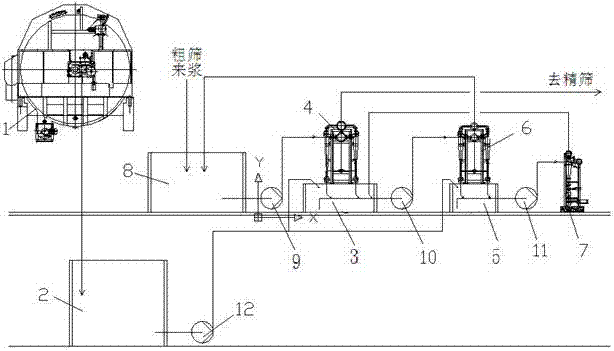

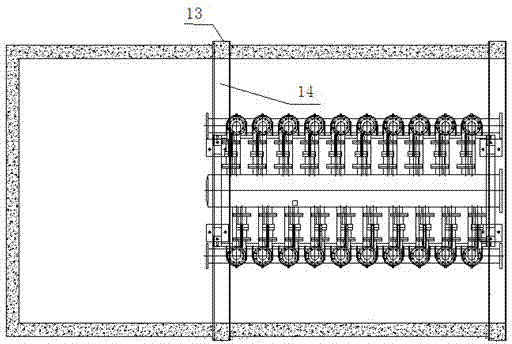

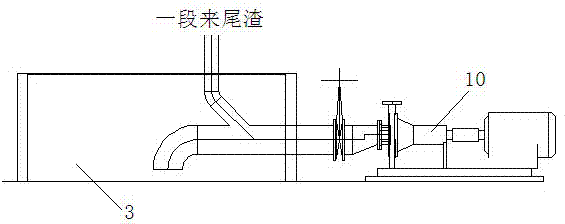

[0018] Such as figure 1 As shown, the pulping low-consistency slag removal system consists of multiple discs (1), turbid white water pool (2), one-stage low-consistency slag removal and white water pool (3), one-stage low-consistency Slag white water pool (5), second-stage low-consistency slag remover (6), third-stage low-consistency slag remover (7), coarse screen fine stock tank (8), first-stage slag removal pulp feed pump (9), second-stage It consists of a slag removal pump (10), a three-stage slag removal pump (11), and a supplementary white water pump (12).

[0019] The pulp from the coarse screen and the good pulp from the second-stage low-consistency slag remover (6) are inserted into the inlet pipe of the first-stage slag-feeding pump (9) at an angle of 45°, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com