Method for film stretching of internally-suspended film of hollow glass and film stretching frame assembly

A glass and film-stretching technology, used in building energy-saving door and window systems, curtain wall systems, and multi-insulating glass fields, can solve problems such as difficulty in ensuring product performance consistency, insurmountable automation in production and processing, and solder joints affecting the smoothness of the film surface. To achieve the effect of easy control of processing technology and quality, improved optical and thermal properties, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Bandage assembly and bandage method

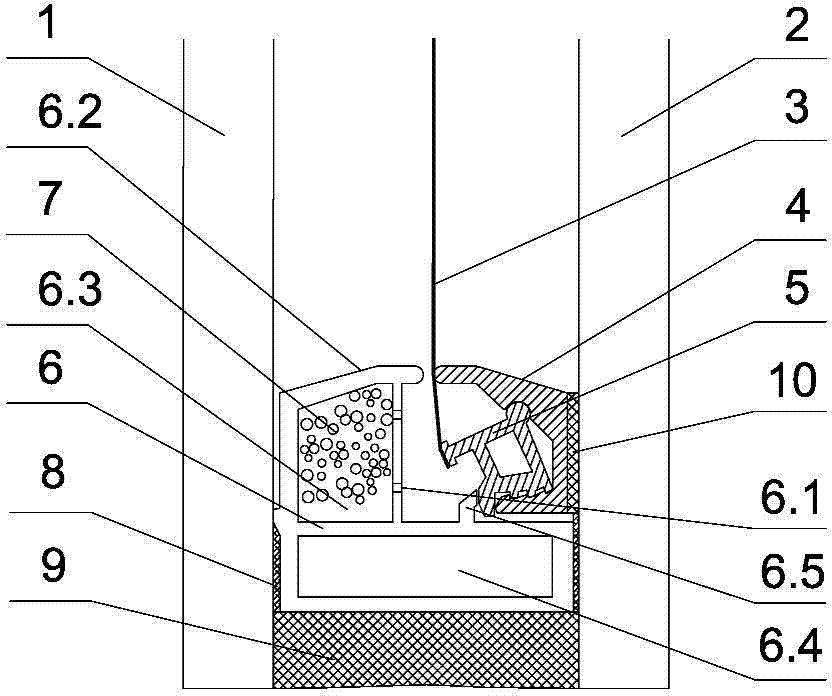

[0046] like figure 1 As shown, the new technology of the hollow glass inner suspension membrane of the present invention is to complete the assembly of the inner suspension membrane of the insulating glass in a purification workshop with a certain level.

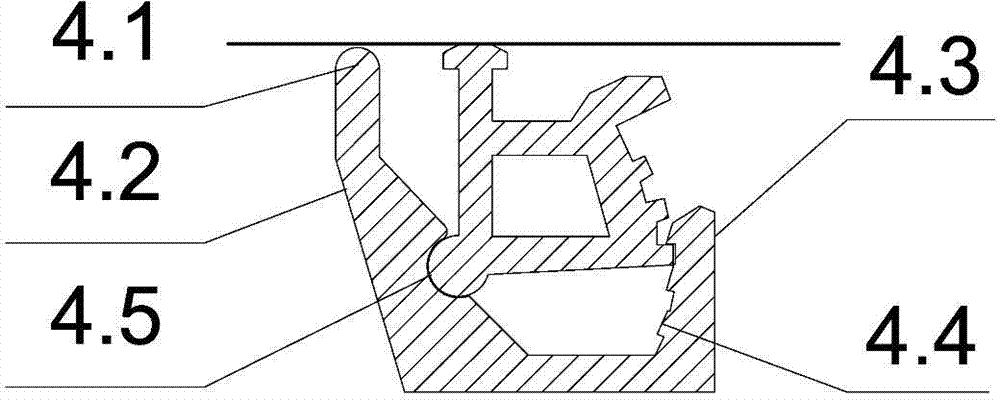

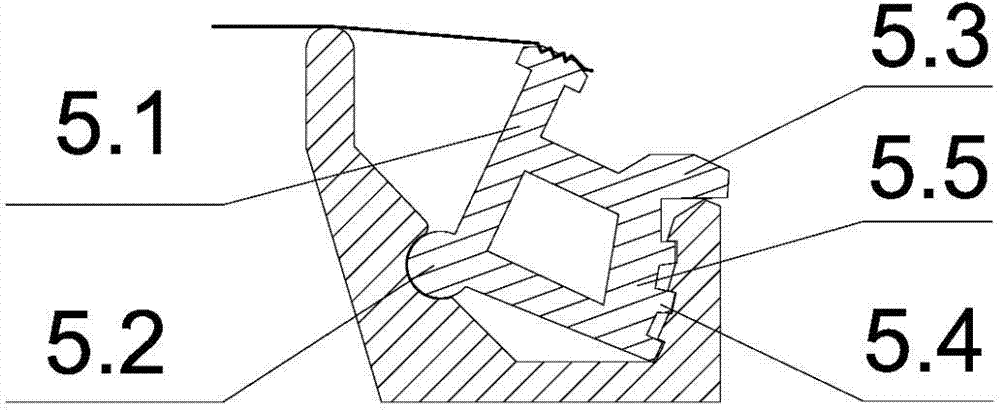

[0047] The stretch film assembly is assembled from a structural frame 4 and a rotating frame 5 . Structural frame 4 is an extruded profile with high modulus polymer (see figure 2 ). The rotating frame 5 is a co-extruded polymer profile with a special structure and a gradient modulus distribution (see image 3 ), the clamp 5.5, the clamp 5.3, the knob 5.2 and the main cavity are all extruded with high modulus raw materials, while the clamp 5.1 requires materials with a small modulus and good elasticity and recovery deformation ability to be co-extruded with the aforementioned parts into a profile. Chuck 5.1 During the co-extrusion process, it is cut in a zigzag ...

Embodiment 2

[0056] Embodiment 2: stretch film frame assembly deformation one

[0057] like Image 6 As shown, the rotating frame can also be replaced by a polymer structural section with a three-claw shape. The common point of the three claws is used as a rotating fulcrum and is also called a turning button. The claw on the side of the rotating frame close to the hollow glass cavity serves as a Decorative end plate (the end is used as the flange of the stretch film), the middle claw of the three-claw shape is the fixed side of the inner suspension film, and the end of the fixed side is a group of protruding chucks distributed at intervals, which are in direct contact with the film , with good elasticity and low modulus, and a tight contact point between the film and the chuck that can move in a small range is obtained by welding; the outer claw of the rotating frame close to the sealing structure of the outer end of the insulating glass has a backstop The locked tooth socket is called ...

Embodiment 3

[0061] Embodiment 3: stretch film frame assembly deformation two

[0062] like Figure 7 As shown, the rotating frame is also replaced by a polymer structural profile with a three-claw shape in cross-section, wherein the rotating fulcrum, that is, the turning button, is arranged on the fixed plate of the L-shaped structural frame near the inner end, and cooperates with the rotating fulcrum, that is, the turning button. The grooves are arranged on the rotating frame, and the processing and assembly of the stretch film assembly are as described in Examples 1 and 2.

[0063]

[0064] The present invention has following characteristics:

[0065]The rotating frame and the structural frame, which are composed of co-extruded polymer profiles with special structure and gradient modulus distribution, rotate around the fulcrum in the structural frame through the rotating frame, driving the chuck on it to pull the plastic film outward along the film periphery. Tighten, the chuck c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com