Method for testing activity of denitration catalyst of selective catalytic reduction (SCR) system of thermal power plant on site

A technology of SCR system and denitration catalyst, which is applied in the field of selective catalytic reduction of flue gas, can solve the problems of cumbersome steps, poor controllability, hidden dangers, etc., achieves simple and convenient operation, strong practicability, and ensures accuracy and representativeness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

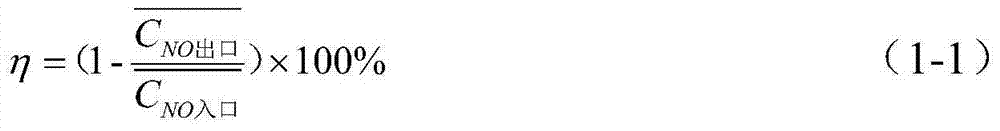

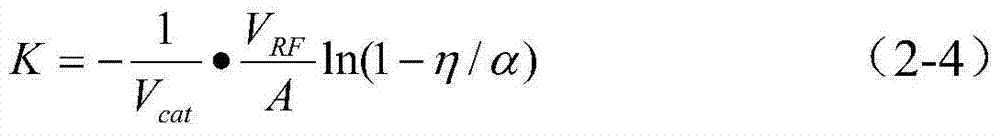

[0028] (1) Measure the average denitrification efficiency. Equipped with a 3012 flue gas analyzer produced by China Qingdao Laoying Company. Stabilize the boiler load involved in the proposed on-site test of the denitration catalyst activity of the SCR system of the thermal power plant, and count the NH involved in the proposed on-site test of the denitrification catalyst activity of the SCR system of the thermal power plant 3 NH in storage tank 3 quantity. Use conventional methods to take the NH 3 NH in storage tank 3 Mix with air to make NH 3 3vol% NH 3 mixture with air, the resulting NH 3 3vol% NH 3 The mixture with air is uniformly sprayed into the denitrification reactor of the SCR system of the thermal power plant to be tested on site. After the working condition of the SCR system tends to be stable, the on-site test of the activity of the SCR denitrification catalysts in each layer of the SCR system is started.

[0029](1.1) Using conventional methods, through t...

Embodiment 2

[0049] (1) Measure the average denitrification efficiency. Equipped with a 3012 flue gas analyzer produced by China Qingdao Laoying Company. Stabilize the boiler load involved in the proposed on-site test of the denitration catalyst activity of the SCR system of the thermal power plant, and count the NH involved in the proposed on-site test of the denitrification catalyst activity of the SCR system of the thermal power plant 3 NH in storage tank 3 quantity. Use conventional methods to take the NH 3 NH in storage tank 3 Mix with air to make NH 3 5vol% NH 3 mixture with air, the resulting NH 3 5vol% NH 3 The mixture with air is evenly sprayed into the denitrification reactor of the SCR system of the thermal power plant to be tested on site. After the working condition of the SCR system tends to be stable, the on-site test of the activity of the SCR denitrification catalysts in each layer of the SCR system is started.

[0050] Following steps (1.1)~(1.3) are with embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com