Quartz resonant element

A technology of resonant components and quartz, which is applied in the field of resonators, can solve problems such as poor symmetry, limited increase in electric field strength, and low resonance stability of resonant components, and achieve the effects of enhanced stability, increased field strength, and improved excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

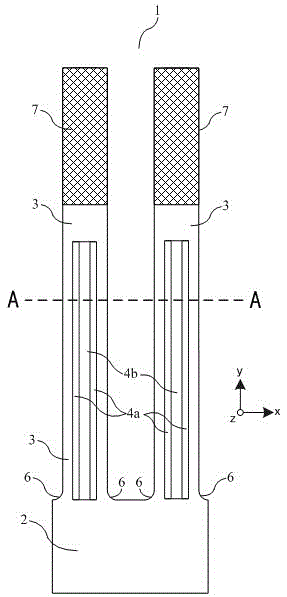

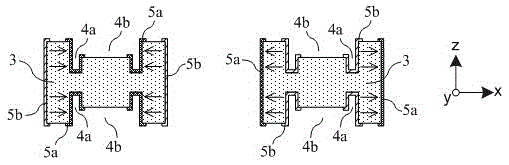

[0019] like Figure 1a and Figure 1b As shown, the quartz resonant element 1 of the present invention includes a base 2 for mounting and fixing and two resonant beams 3, which are arranged parallel and symmetrically along the Y direction and work in a width bending resonant mode. One end of the two resonant beams 3 is connected to the base 2 , and chamfers 6 are provided on the left and right sides of the resonant beams connected to the base to smoothly connect with the base, so as to improve the reliability of the quartz resonant element 1 . The front and rear surfaces of the resonant beam 3 are respectively provided with symmetrical grooves, and the opening direction of the grooves is perpendicular to the vibration direction of the resonant beam. The grooves are composed of deep grooves 4a parallel on both sides and shallow grooves 4b located between the two deep grooves 4a and integrated with the two deep grooves. The inner wall of the groove and the two side walls of the...

Embodiment 2

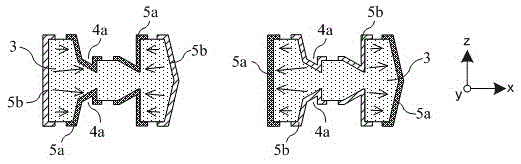

[0026] like Figure 2a and Figure 2b As shown, the structure of the quartz resonant element of this embodiment is similar to the structure of the quartz resonant element of embodiment 1, the difference is that the resonant beam 3 is only provided with grooves on one of the front and rear surfaces. To highlight the shape of the surface grooves, Figure 2a Electrodes are not shown.

[0027] For thinner resonant beams, when the grooves are made on both sides at the same time, the deep groove 4a is easy to etch through, which reduces the dynamic strength of the resonant beam 3. At the same time, the dynamic impedance of the resonant beam 3 will increase when it resonates, reducing the quartz Stability of the resonant element. The structure of the resonant beam 3 with grooves formed on one side in this embodiment is more suitable for the manufacture of a miniaturized quartz resonant element 1 based on a thinner substrate. Since the groove is set on one side, the metal mass blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com