Red trimming and punching compound process of claw pole

A technology of trimming, punching and composite technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, pre-forging of middle holes, corrosion of cutting fluid, etc., and achieve the production site and surrounding areas. Improvement of the environment, improvement of production safety and production efficiency, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A claw pole red trimming and punching composite process, which has the following process steps: a. blanking; b. hot forging, and simultaneously forging the center pre-holes on both ends of the claw pole blank; c. using a red trimming punching compound die The two processes of red trimming and red punching of the claw pole blank are completed at one time; d, shot blasting; e, shaping; f, turning plane; g, finishing turning.

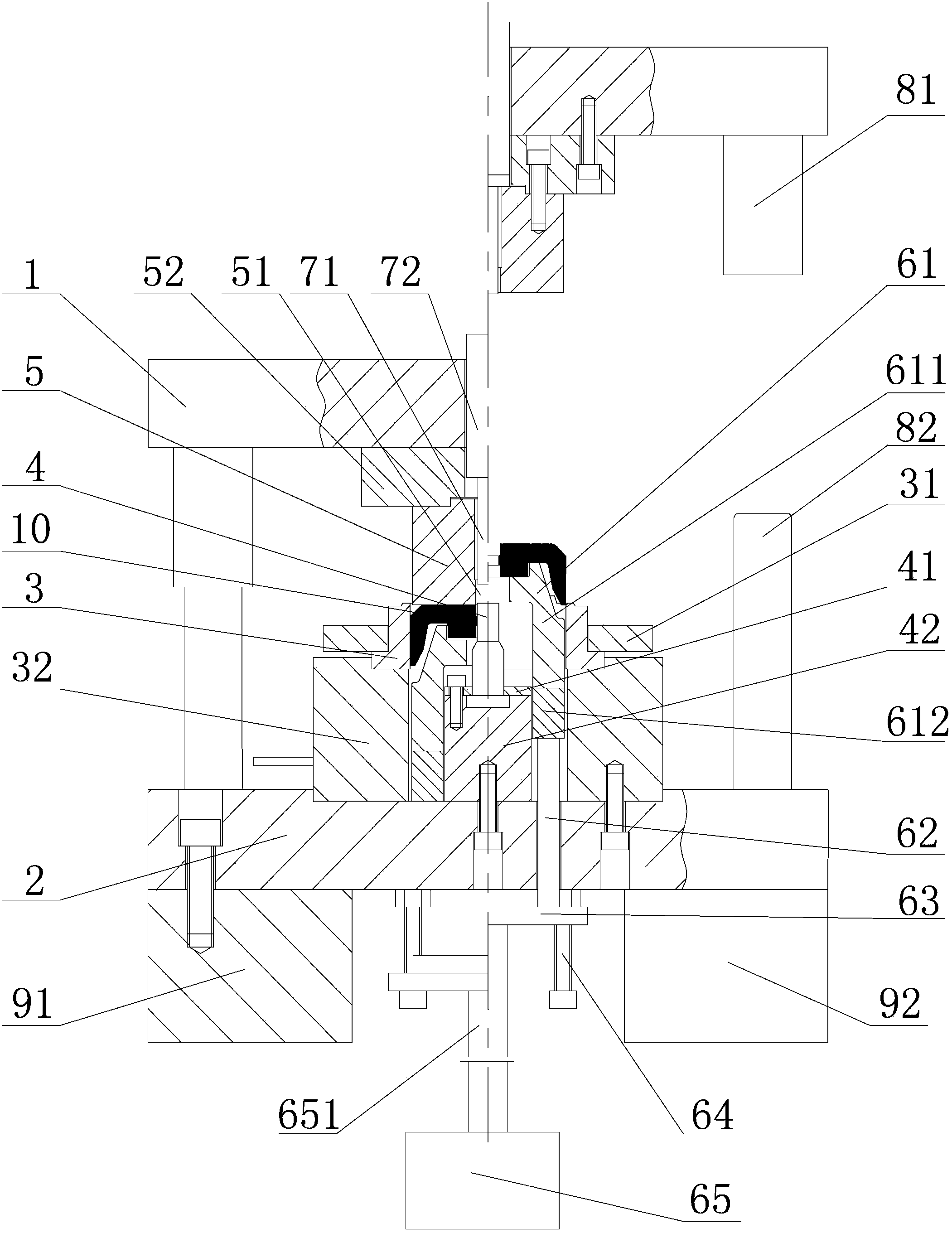

[0019] Such as figure 1 As shown, the above-mentioned red trimming and punching composite formwork includes an upper template 1 and a lower template 2 arranged up and down oppositely, and the two sides of the bottom surface of the lower template 2 are fixedly connected with two lower support seats 91, 92 respectively. The side of the lower template 2 facing the upper template 1 is fixedly connected with a trimming die 3 for placing the formed claw pole hot forging blank 10 and performing red trimming on it and for red punching the claw pole hot forg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap