Fiber bragg grating stretching type device for monitoring tensile force of steel wire rope of mine lifting equipment and method

A fiber grating and monitoring device technology, which is applied to lifting equipment, elevators, transportation and packaging in mines, can solve the problems of difficulty in finding hidden safety hazards in time, being easily affected by complex environments, and low precision, and can solve the problems of strain and Temperature cross-sensitivity, improving measurement accuracy and sensitivity, and ensuring the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

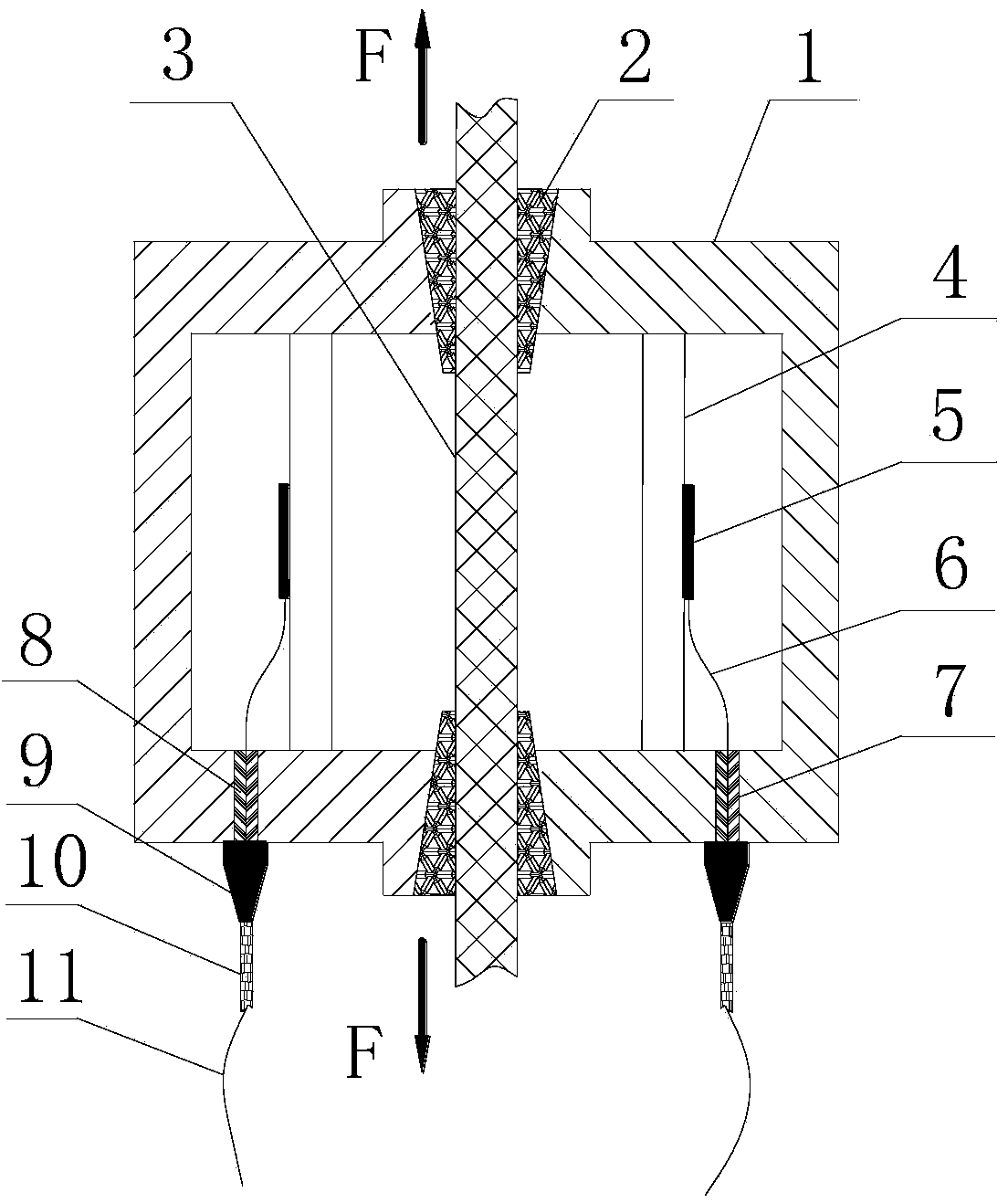

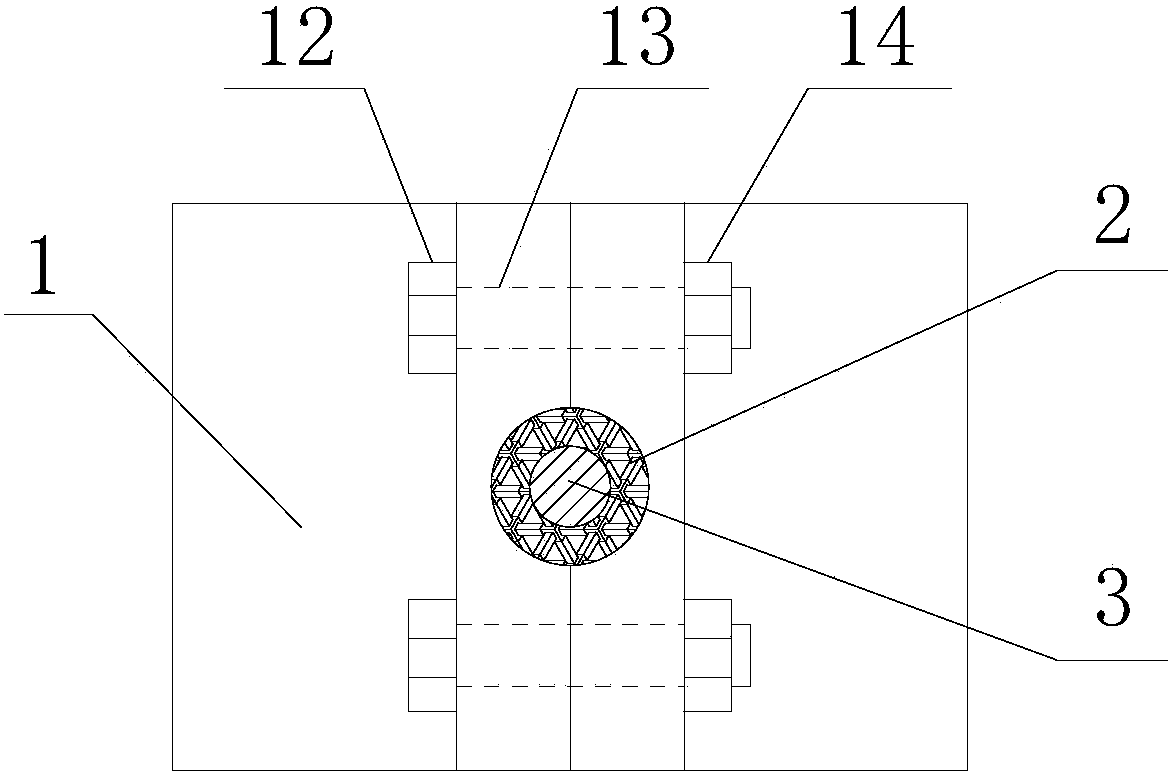

[0024] Such as figure 1 and figure 2 As shown, the optical fiber grating tensile type mine hoisting equipment wire rope tension monitoring device of the present invention includes a package casing 1, an anti-skid wedge-shaped rubber ring 2, a steel wire rope 3, an elastic measuring rod 4, an optical fiber grating 5, an optical fiber 6, and an optical fiber outlet hole 7, Sealant 8, optical fiber connector 9, armor protection rubber 10, optical fiber pigtail 11, bolt 12, bolt hole 13, fastening nut 14. The packaging shell 1 is buckled symmetrically to fix the steel wire rope 3, and an anti-skid wedge-shaped rubber ring 2 is installed between the packaging shell 1 and the fixing part of the steel wire rope 3. One end of the inside of 1 is small in size; the top and bottom of the package shell 1 are symmetrically provided with bolt holes 13, and the bolts 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com