Preparation method of 2, 4-dichloroaniline

A technology of dichloroaniline and m-dichlorobenzene, which is applied in the field of preparation of 2.4-dichloroaniline, can solve the problems of low product purity, difficulty in keeping the production environment clean, and high energy consumption, so as to reduce energy consumption and protect the environment Meaning, effect of keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further illustrate the technical solution of the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0015] The purity of 2-(4-hydroxyphenoxy)propionic acid, ethanol and toluene used in this example are all ≥99%.

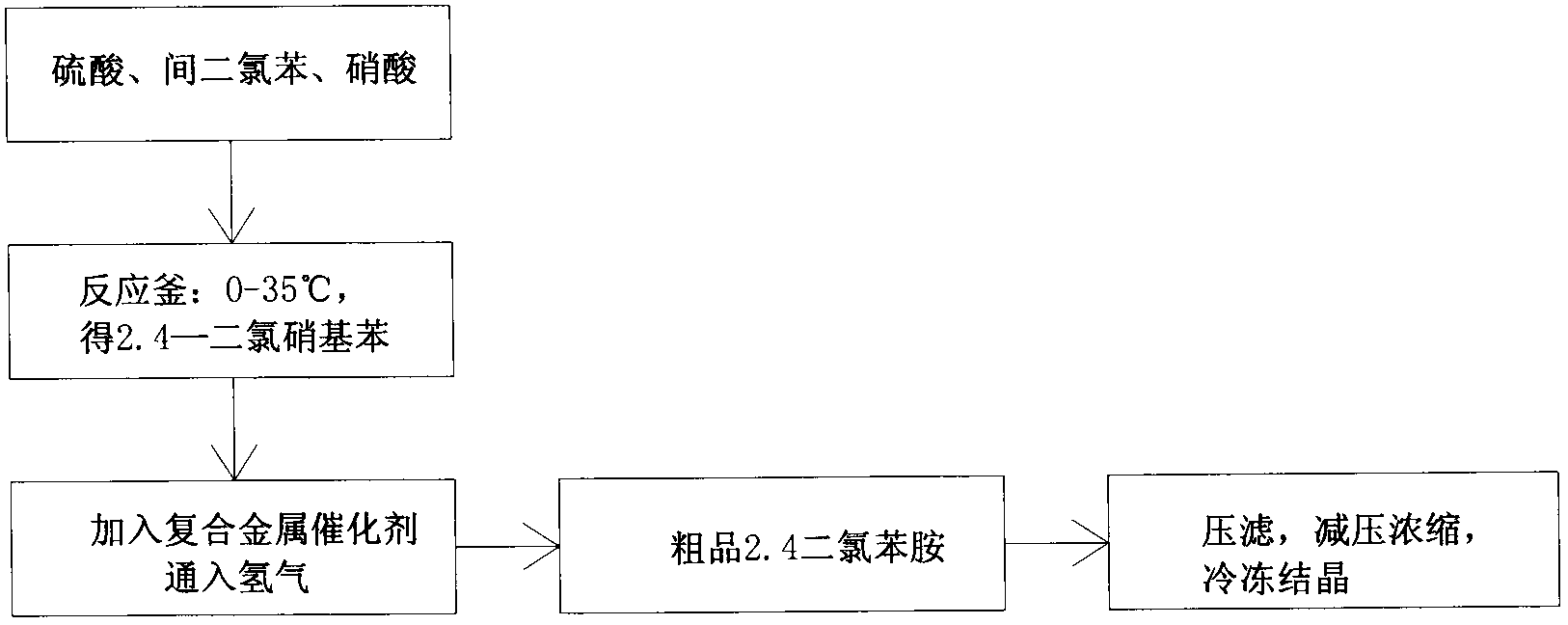

[0016] A preparation method for 2.4-dichloroaniline, comprising the following steps (such as figure 1 shown):

[0017] (1), raw material 160kg sulfuric acid and m-dichlorobenzene are added in the reactor, nitric acid is added dropwise under stirring, nitric acid: m-dichlorobenzene=1: 1.05-1.3 (molar ratio), the temperature in the reactor is controlled at 0- 35°C, the reaction time is 1 hour, after the reaction is completed, the waste acid is filtered off, the product is washed with 1% a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com