Method for breaking down fibrous material

A fiber material and decomposer technology, applied in the field of decomposing fiber materials, can solve problems such as low operating cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

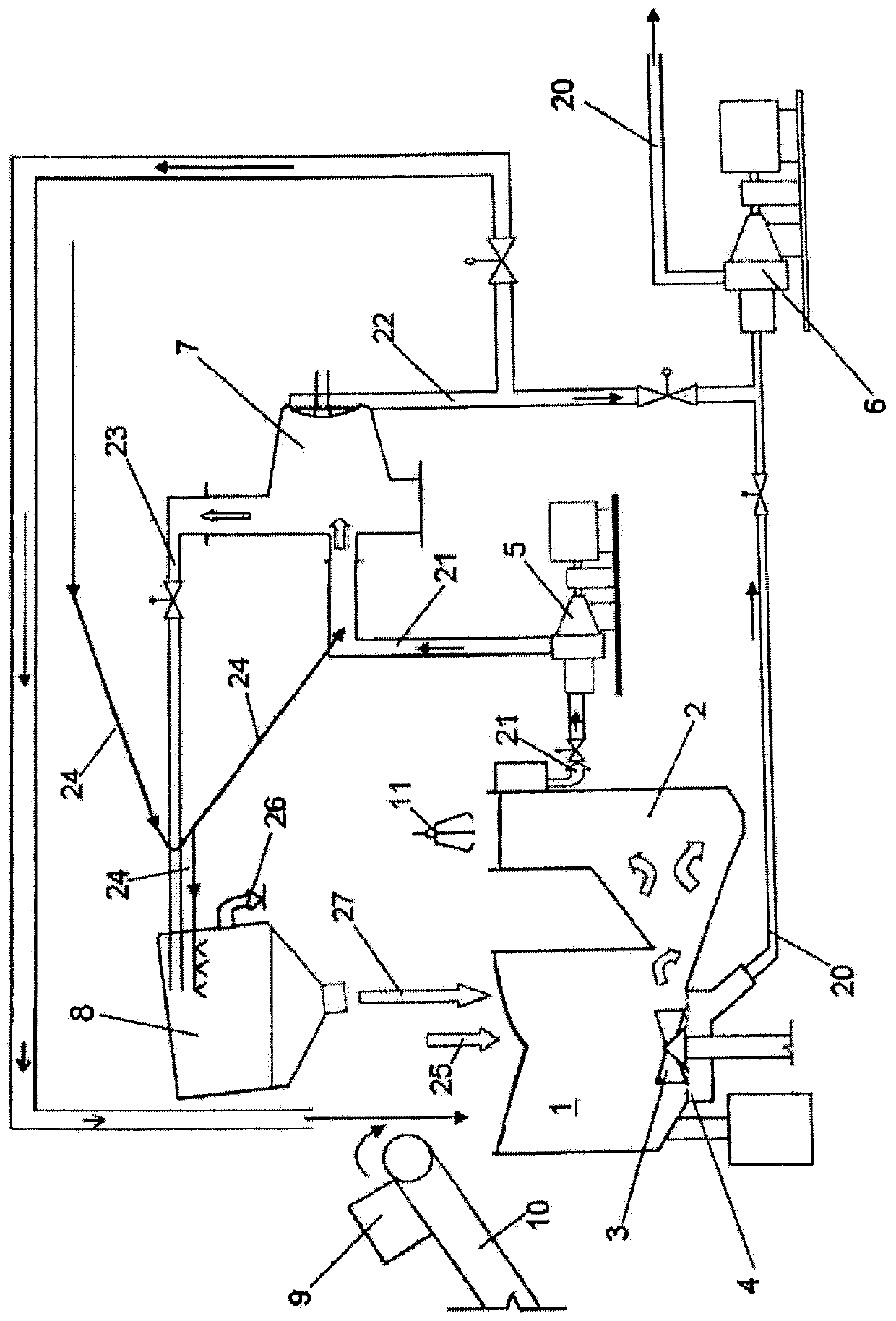

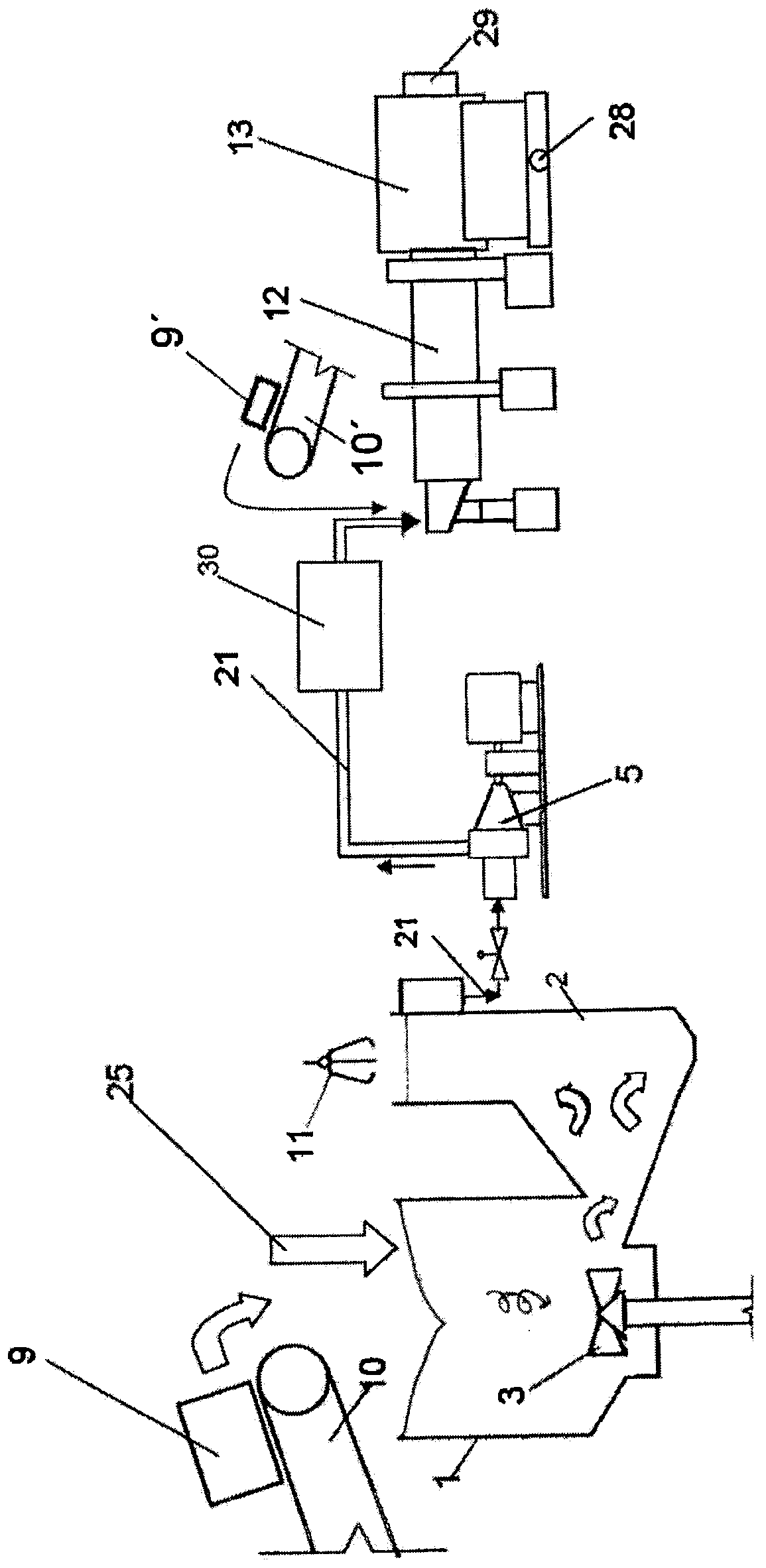

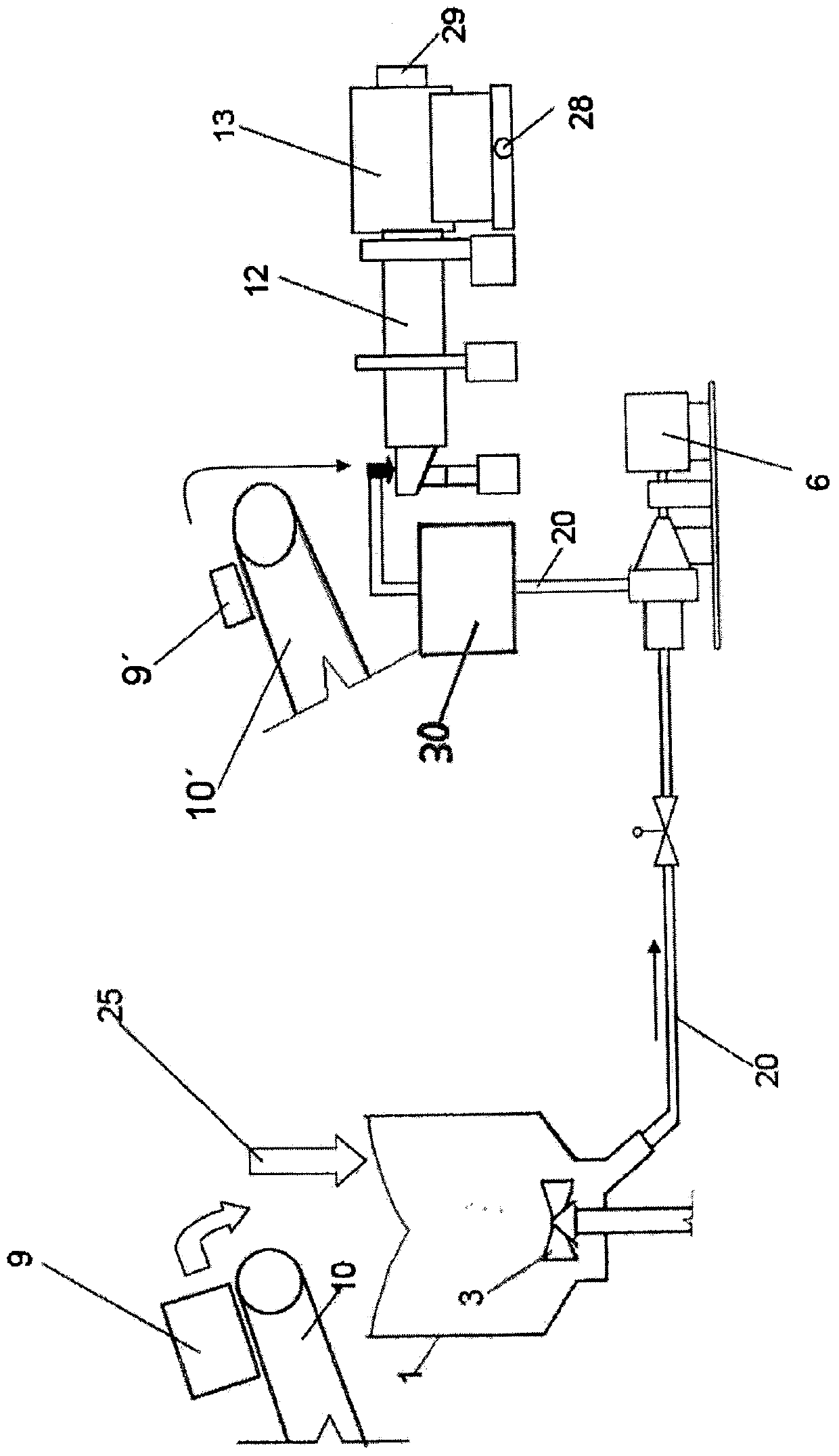

[0023] figure 1 A schematic diagram of a conventional method for decomposing waste paper is shown in . Here, the fibrous material 9 , ie the waste paper mass, is conveyed via a conveyor belt 10 to a material disintegrator 1 (mixer). The waste paper is mixed with water 25 in the material disintegrator 1 , where the waste paper is disintegrated and a fibrous material suspension is formed. In this case, the decomposition of the material in the mixer 1 is supported by the rotor 3 . Most of the decomposed fibers pass through the screen 4 below the rotor 3 to the product material chamber from which the product material flow 20 in the material decomposer 1 is output. The product material flow 20 is then conveyed by the product material pump 6 to further units for further processing.

[0024] A portion of the fibrous material suspension and in particular the disturbing material contained in the waste paper leaves the material disintegrator 1 as a slag stream 21 and reaches the sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com