Method for monitoring rammed point soil stabilization state vibration in real time

A soil reinforcement and real-time monitoring technology, which is applied in soil protection, on-site foundation soil survey, construction, etc., can solve the problems of rough reflection of foundation reinforcement status, collapsibility coefficient to be studied, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

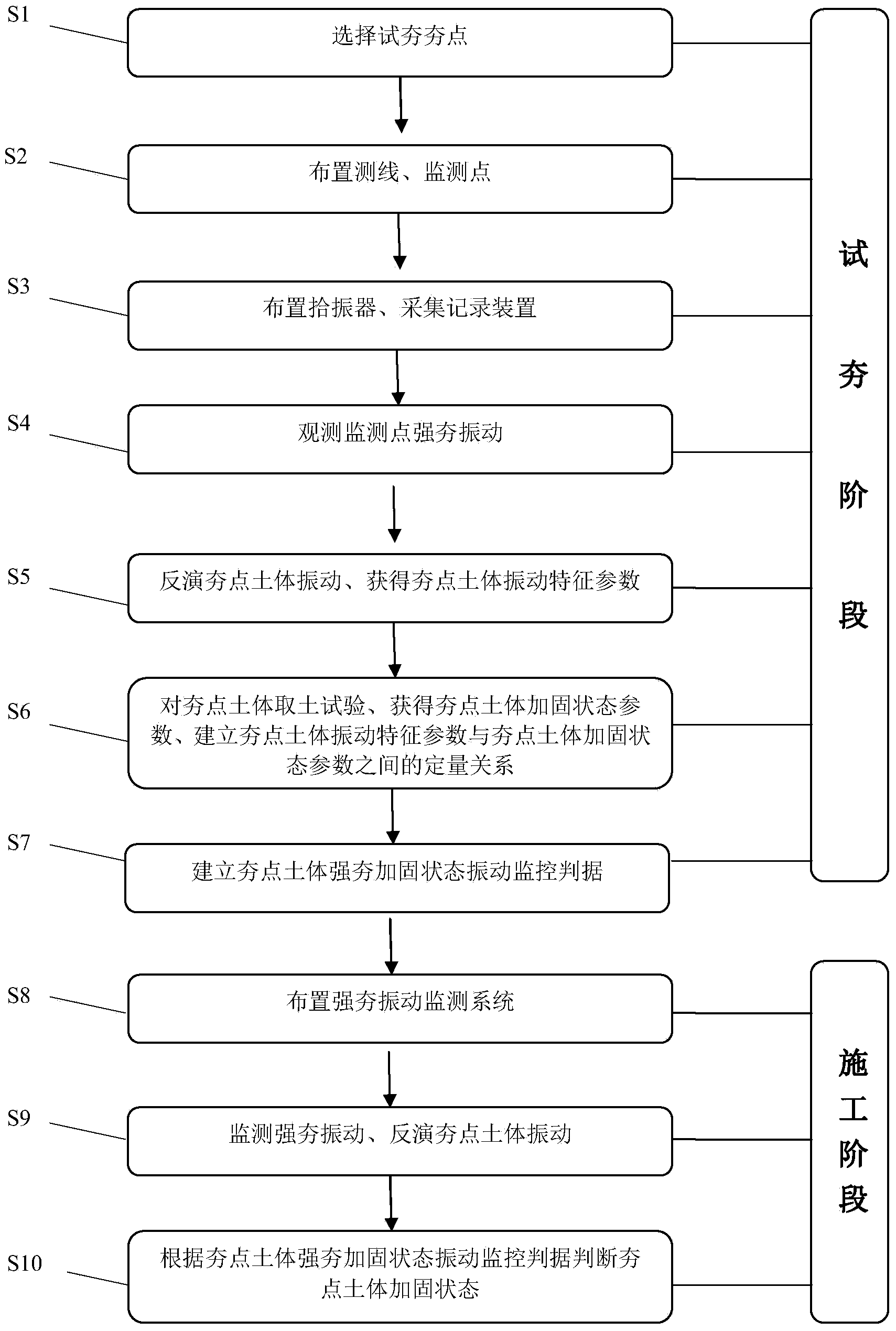

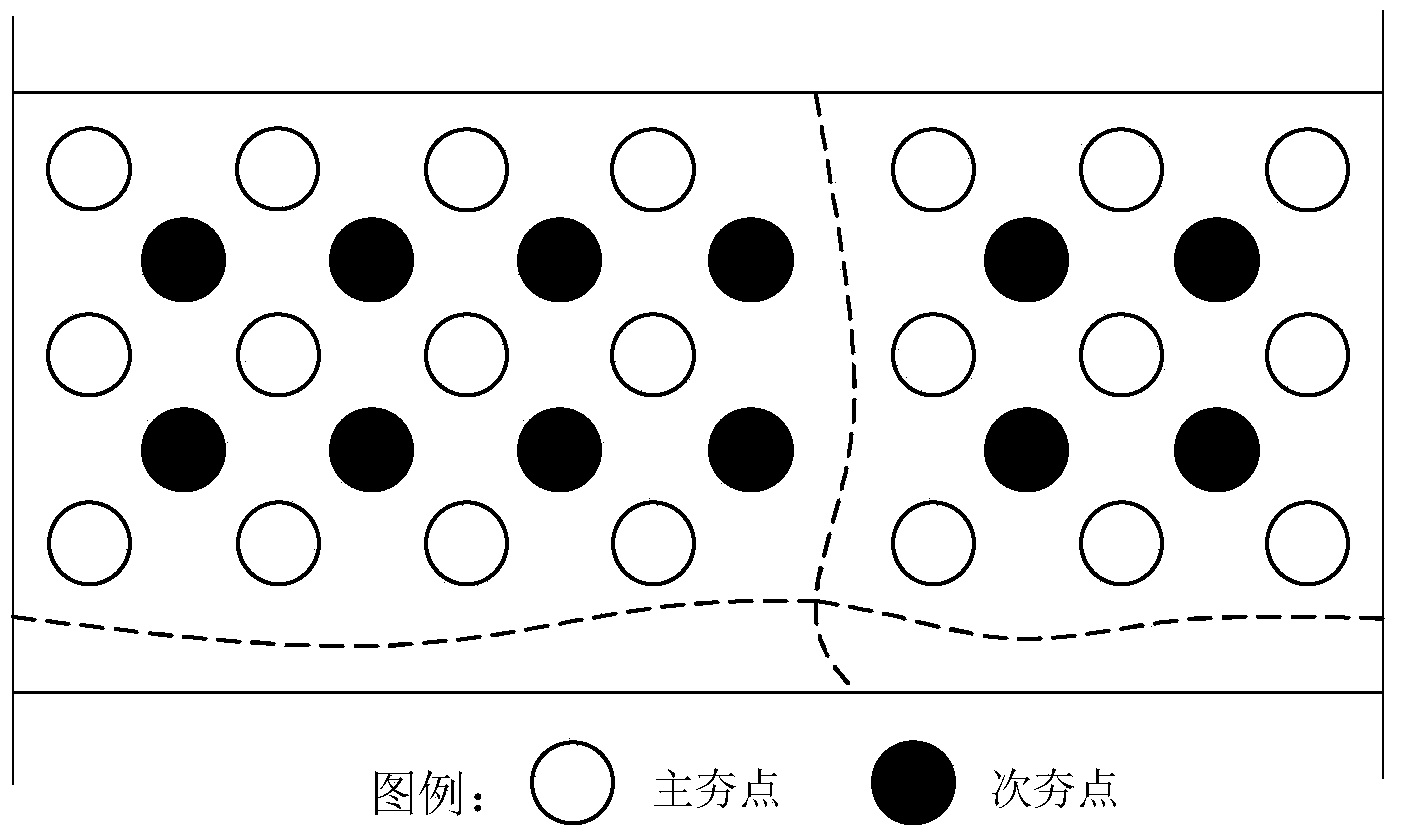

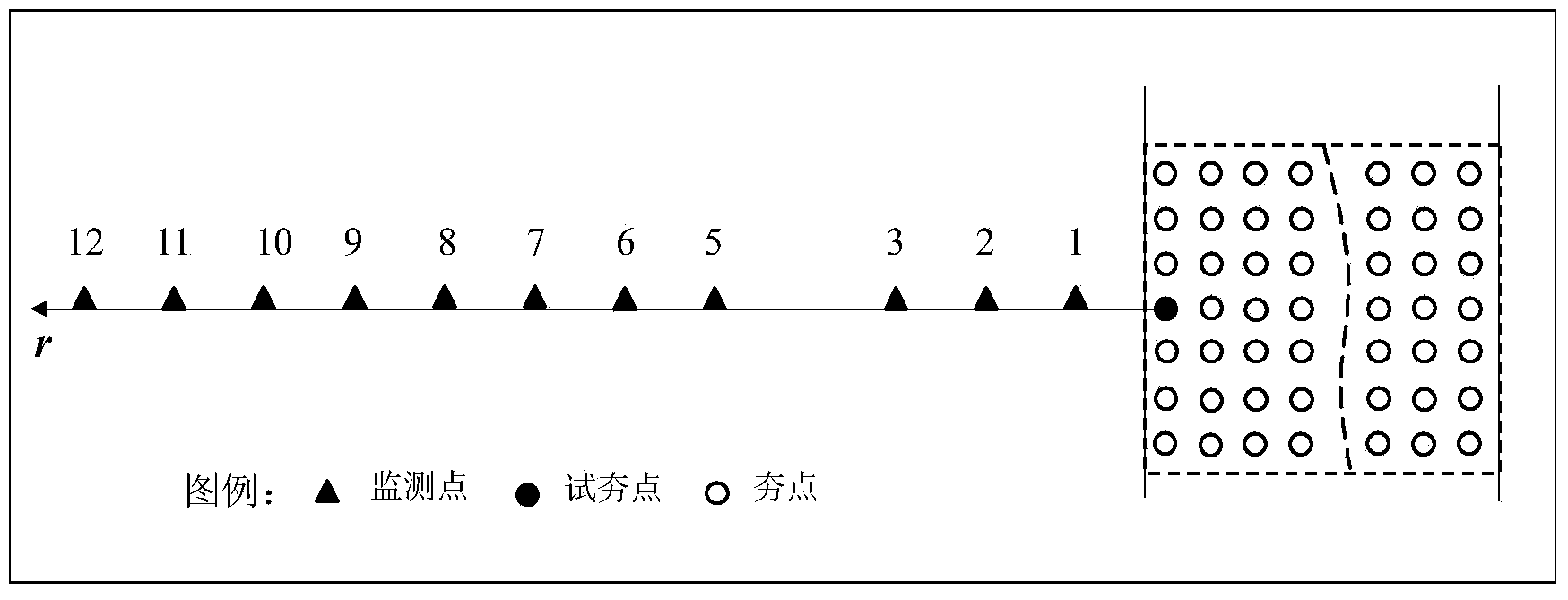

[0058] Such as Figure 1 to Figure 3 as shown, figure 1 It is a flow chart of a method for real-time monitoring of the vibration of the tamping point soil reinforcement state of the present invention; figure 2 It is a schematic diagram of plane layout of tamping points in the test tamping stage of a method for real-time monitoring of vibration of tamping point soil reinforcement state of the present invention; image 3 It is a schematic plan layout diagram of a dynamic tamping vibration monitoring system during the dynamic tamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com