Wall-mounting-type vertical coal bunker without coal feeder chamber

A coal feeder and wall-mounted technology, which is applied in the field of wall-mounted vertical coal bunkers, can solve the problems of reduced stability of the overall load-bearing structure of the coal feeder chamber, unsafe and efficient use of coal bunkers, and inward movement of both side walls or columns. , to achieve the effects of reducing construction and maintenance costs, wide applicability, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

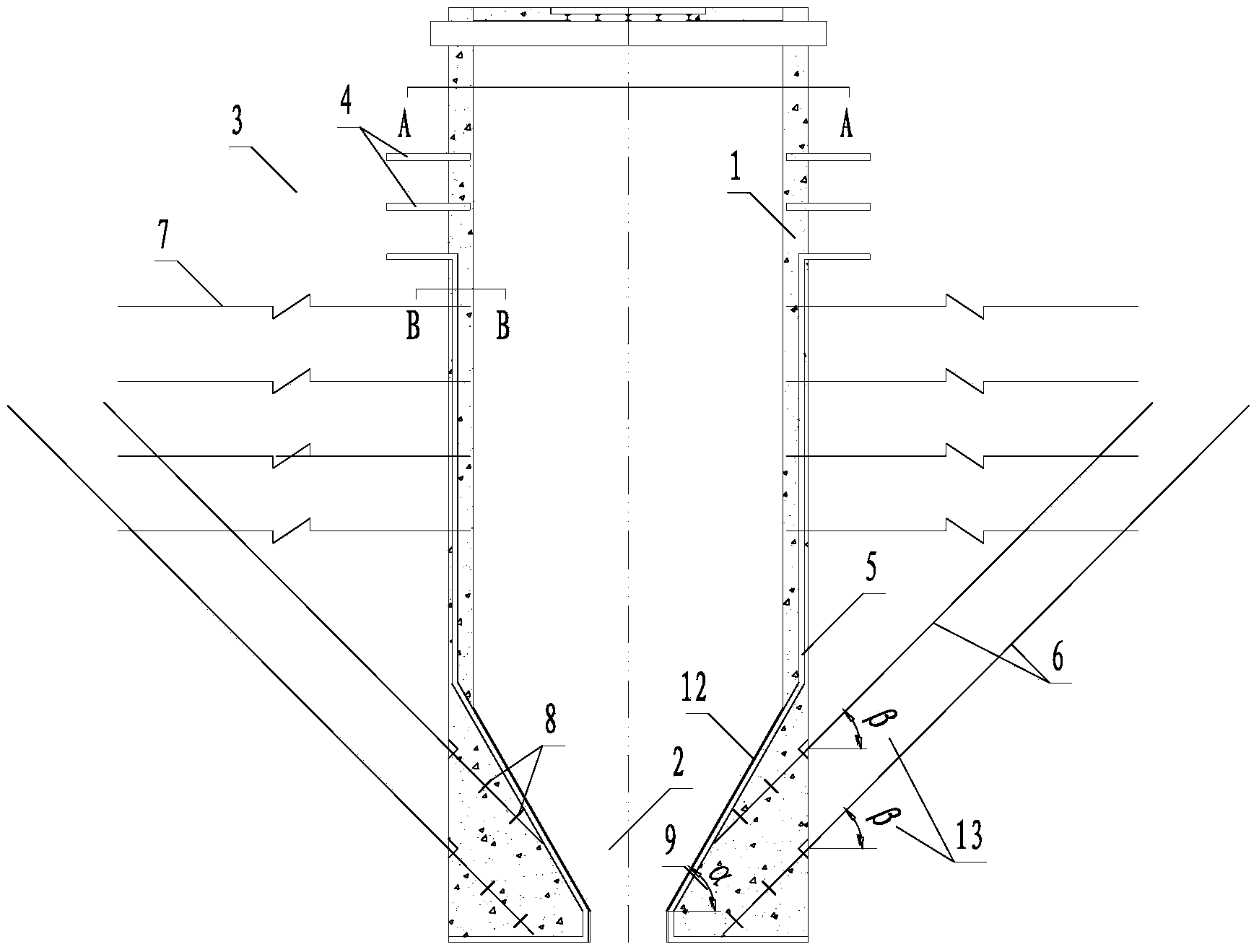

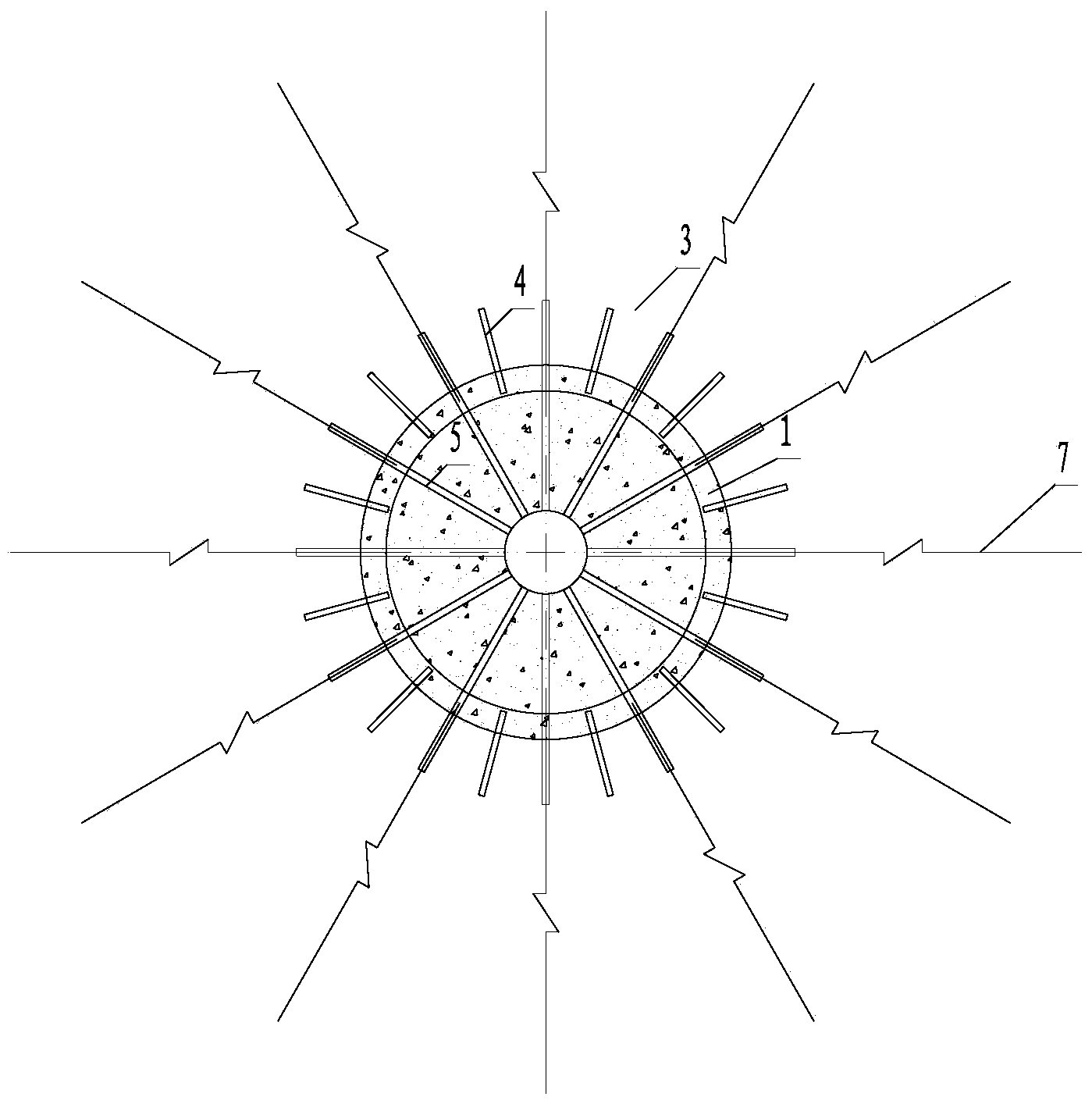

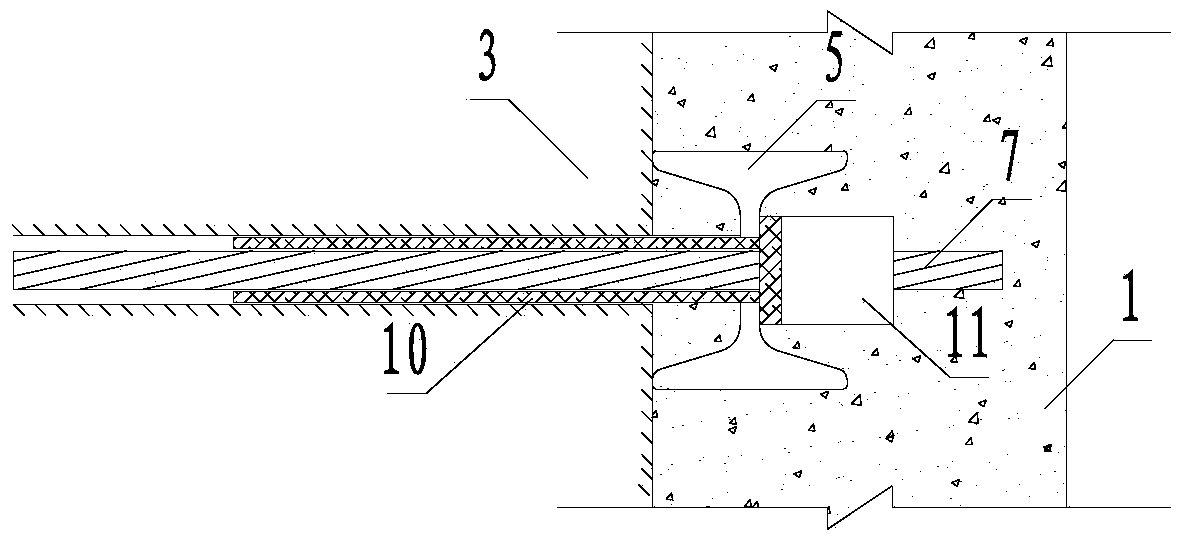

[0023] Such as figure 1 , figure 2 As shown, the wall-mounted vertical coal bunker without coal feeder chamber of the present invention comprises a cylindrical reinforced concrete silo body 1, a frustum-shaped constriction 2 at the bottom of the cylindrical reinforced concrete silo body 1, and a frustum-shaped constriction slope The angle α(9) with the horizontal direction is set according to the repose angle of coal not less than 55°. The inclined surface of the frustum-shaped constriction 2 is laid with an impact-resistant and wear-resistant lining 12 made of inorganic composite building materials. Along the outer wall of the cylindrical reinforced concrete silo 1 and the inner wall of the conical constriction 2, a plurality of I-shaped steel silo brackets 5 are arranged at intervals, and the I-shaped steel silo in the cylindrical reinforced concrete s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com