Resistance top-mounted micro-propeller and preparation method thereof

A micro-propulsion and top-mounted technology, which is applied in the field of micro-propulsion technology and micro-electromechanical systems, can solve the problems of MEMS process incompatibility, low fuel energy utilization rate, and unstable device performance, so as to improve the air flow mode and increase fuel energy. Effect of Utilization, Parameter Sensitivity Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

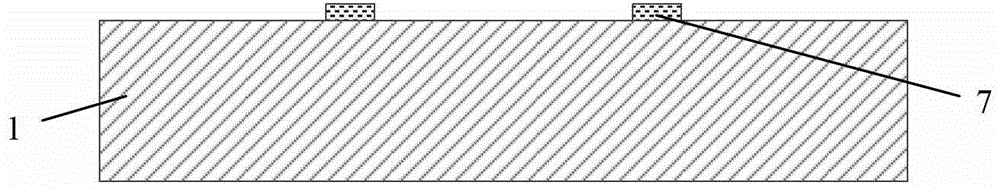

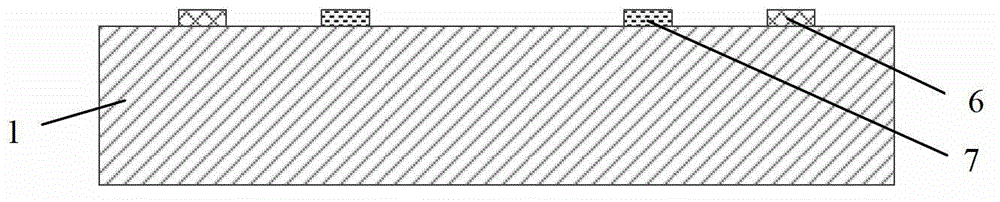

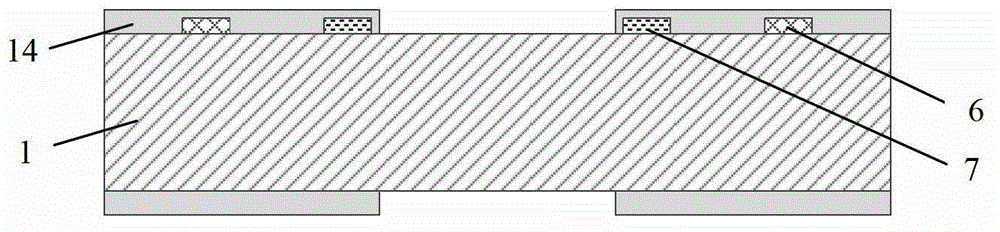

[0031] In this embodiment, a resistive top-mounted micro-propeller as shown in Figure 2 is provided, the propeller includes an upper structure 1 with a thickness of 500 μm, and the material is monocrystalline silicon; an intermediate structure 2 with a thickness of 1000 μm, The material is monocrystalline silicon; the lower layer structure 3 with a thickness of 500 μm is made of heat-resistant glass; it is characterized in that: in the middle of the upper layer structure 1, there is a nozzle 4 of a laval structure with contraction in the middle and expansion at both ends, and the expansion at both ends of the nozzle 4 The largest part is a square of 500μm*500μm, and the smallest part of the middle contraction is a square of 150μm*150μm. The ignition resistor 7 with a thickness of 300nm is distributed around the nozzle, and the ignition resistor 7 is connected to the upper transfer electrode 6 with a thickness of 300nm; the ignition resistor 7 It consists of 6 ring-shaped resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com